Lithoz announced a new center of excellence for bio ceramic 3D printing.

The Austrian company is one of the very few manufacturers of ceramic 3D printers. Ceramic is an unusual material that is underused in industry. It’s a material that is very hard, and provides extreme thermal and chemical resistance.

It’s ideal for use with implants into the human body, a practice that could be called “bio ceramics”.

That’s the focus of the new COE being set up by Lithoz and HiMed, a supplier of high quality ceramic materials.

The COE will be set up at HiMed’s NY headquarters in Long Island, New York. What will take place in the COE? Lithoz explains:

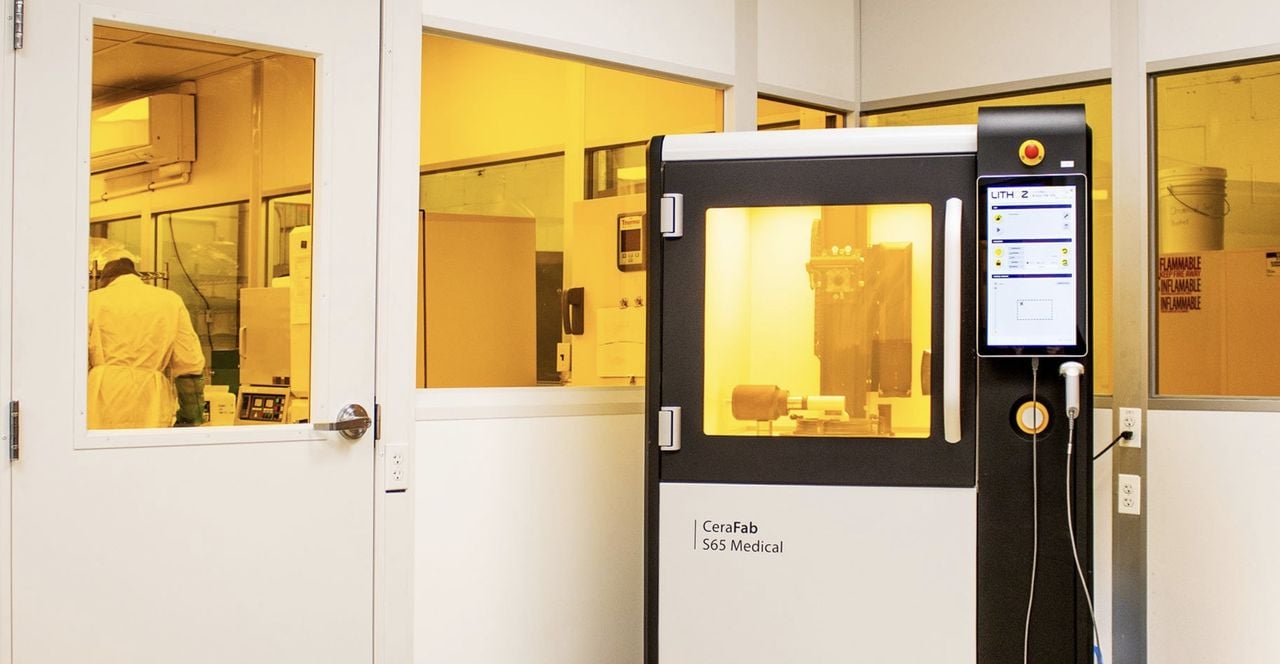

“The center will provide a comprehensive suite of services, including design support and optimization, SEM imaging, material analysis and characterization, biomaterial customization, and bioceramic 3D printing using a Lithoz CeraFab S65 Medical printer.”

But why? There’s a good reason, as they explain further:

“The company aims to promote the development of innovative manufacturing processes for bioceramic materials and help customers explore new compositions and manufacturing techniques that may have been previously out of reach for some companies. The BCoE will particularly benefit medtech startups and other businesses looking to cost-effectively prototype and optimize designs that use bioceramics.”

This is quite important because 3D printed ceramics are still quite new to industry. Change is always hard for companies, and the best way to trigger change is to show the management directly. That’s challenging if you don’t have the equipment or skills to provide a demonstration or experiment, but far easier when there’s a handy demonstration center of excellence nearby.

Even if a company doesn’t know how to solve an application problem, the COE will be able to provide expertise to figure out solutions. In the end this could lead to new production applications for bio ceramics, and ultimately more 3D printer and ceramic material sales for Lithoz and HiMed.

COE’s are always a good sign of progress for new technologies.