A new form of 3D print material has been sourced from biodiesel fuel.

Diesel fuel is in widespread use across the globe, particularly in trucks and heavy machinery. It’s not so much used in smaller automobiles now, so it may not be as visible. But it’s a pervasive fuel.

However, it’s also a significant generator of greenhouse gases, and should ultimately be phased out.

But what would you replace it with? There are electric cars, but few electric trucks and even fewer electric versions of heavy machinery. It would appear that diesel fuel would be in the cards for quite some time.

One solution that’s being explored is the use of biodiesel fuel. This is pretty much the same as standard fossil-sourced diesel, except it’s sourced entirely from biological sources. This changes the diesel into a sustainable fuel, as it is obtained from sustainable sources in a circular manner.

Because of this we are likely to see a gradual increase in the use of biodiesel fuel over the coming decade.

Then it gets more interesting. It turns out that the production of biodiesel fuel generates some waste materials. One of them is matter organic non-glycerol, or “MONG”. Apparently MONG makes up about a quarter of the waste produced by soy biodiesel factories. MONG is typically sent to the landfill, which just isn’t a good thing.

Now, researcher have found a way to make use of the huge amount of waste MONG produced by these plants. They explain:

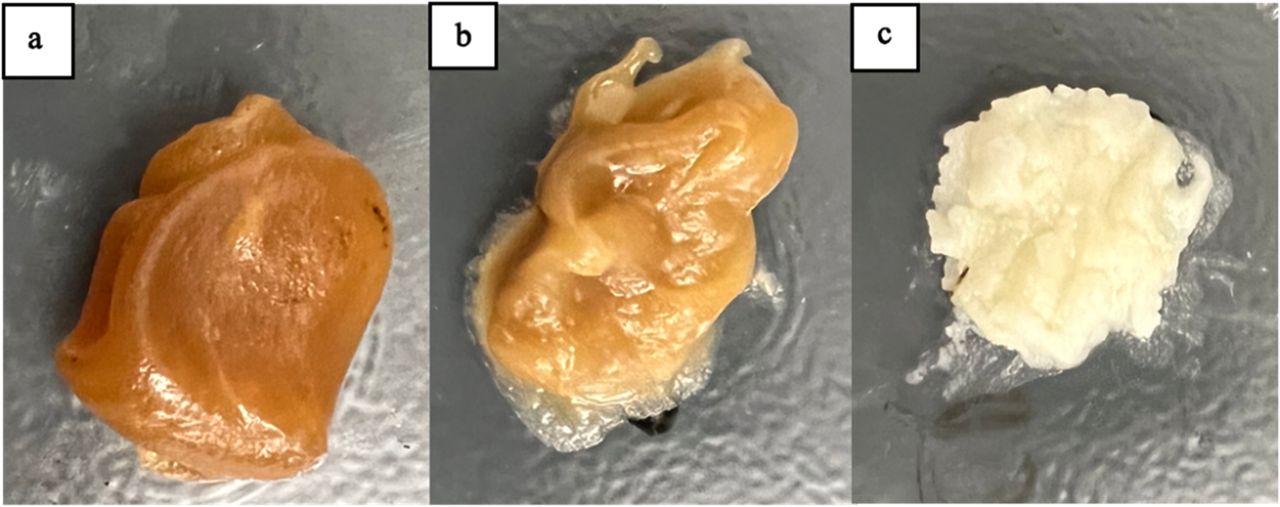

“In this work, soy MONG was characterized for potential use as a copolymer to produce filaments for 3D printing with an intent to add value and redirect it from landfills. As a copolymer, MONG was evaluated to reduce the synthetic polymer content of the natural fiber composites (NFC). Even though the general thermal behavior of the MONG was compared to that of a thermoplastic polymer in composite applications, it is dependent on the composition of the MONG, which is a variable depending on plant discharge waste.”

After some treatments, the resulting copolymer paste could be combined with a thermoplastic to create a usable material.

While the research focused on biodiesel produced using soybeans, the process can also be produced with other substances like biogas, ethanol, etc., made from a wide range of other common sustainable biologics, including palm oil, algae, and even waste cooking oils.

This is a good technology to have in hand as we will inevitably see a dramatic increase in biofuels in coming years.

Via Science Direct