Is 3D printing actually food safe? A study turns conventional thinking upside down.

A paper from last summer entitled “Sanitation Effectiveness of 3D Printed Parts for Food and Medical Applications” explores the current notions of safety for these prints.

What’s the current thinking about FFF 3D printing food safety? Generally it falls into these points:

- The materials may contain toxic chemicals, particularly lead metal in the colorants

- The machine that the materials pass through may contaminate the print as material erodes from the nozzle or other printer components

- The layered structure of FFF prints provides plenty of nooks and crannies for unwashable material to accumulate and cause issues

As a result most people do not use their desktop 3D printer to make objects that will come in contact with food. If so, however, the standard advice is to seal the print with a certified food safe epoxy material.

But what does this study find?

They spent months 3D printing objects and testing them rigorously in kitchens and medical settings. They looked for evidence of pathogen contamination, biofilms, bacteria hiding in layer lines and other pockets of 3D prints that are challenging to clean properly. They tested a variety of cleaning processes, and looked for heavy metal contamination in PLA+ and PETG prints.

Their results on lead contamination are quite interesting. The idea is that as material passes through a brass nozzle, it could pick up lead that’s mixed with the brass. They measured the total amount of lead in a typical nozzle, and determined the amount of lead being exposed to the material — the surface area of the inside.

They also weighed new nozzles versus used nozzles having up to 1000 prints, and found there to be negligible loss of mass. Transforming that to an amount of lead, it was so small their instruments could not pick it up. They suggest that holding a brass key in your fingers might provide more exposure to lead.

They also used a mass spectrometer to measure lead in the materials themselves. They found “no contamination from lead or other heavy metals and toxins were present”.

For colorants, the researchers point out that if using a toxic colorant the manufacturer must list it on the MSDS sheet. But to keep their color recipes secret, they almost always use non toxic colorants. However, the researchers do recommend coating prints in food safe resin when exposing them to consumable liquids.

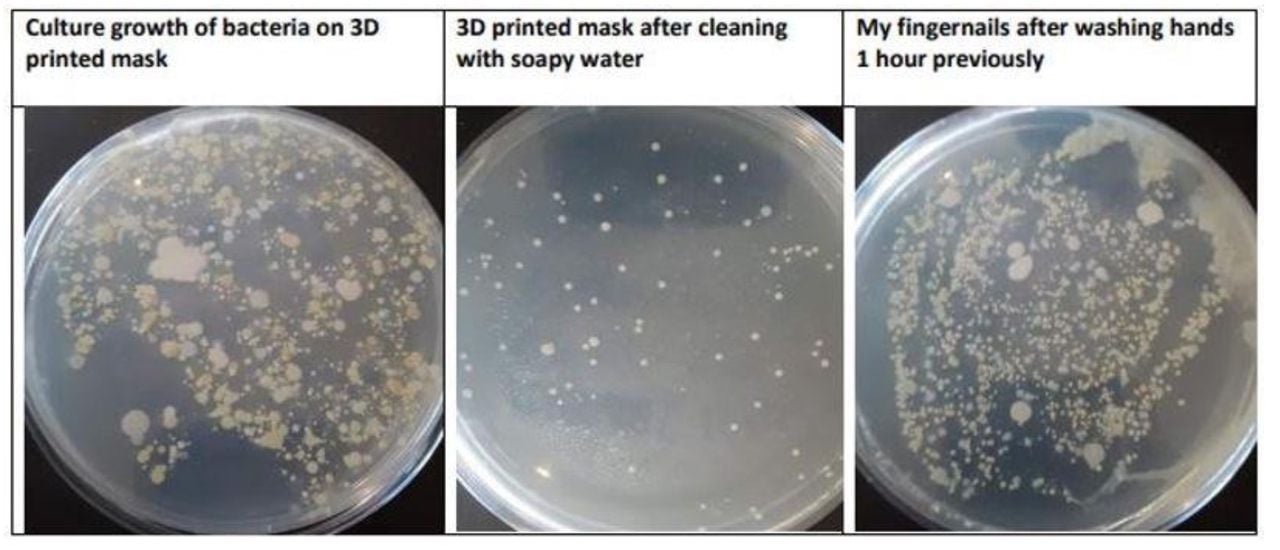

For pathogen analysis, the researchers soaked a number of 3D prints in chicken blood and livers for 24 hours to produce what must be about the nastiest scenario one could imagine. They then set to measure pathogen growth and test a variety of cleaning approaches.

They found that even washing the nasty prints with non-concentrated soap and water did remove 90% of pathogens. By adding a bleaching step they were able to significantly reduce the pathogen presence. They explain:

“Experimental results proved that baking soda, when used with soapy water, does eliminate biofilms by chemical and physical action. Further testing helped authors conclude that a 2-minute room temperature bleach water soak (200ppm) without baking soda scrub, helped dissolve biofilms and pathogens to safe levels when tested by surgical technicians. It has been concluded from the results that the best method of cleaning 3D printed parts is to use warm soapy water with a small (1/8th teaspoon or 2g) amount of baking soda on a dish rag. Spend about 15 seconds washing and scrubbing with a small amount of force, as to not damage the part. Once clean, either soak in cool bleach water for 1-2 minutes of a 200ppm molarity, 1 tablespoon bleach per gallon of water or apply 70% or greater IPA by soaking for 1 minute.”

This study overturns conventional wisdom on 3D print food safety — as long as participants actually perform the steps described above.

I encourage you to review this study; it’s easy to read and quite enlightening as they explore various ways to clean your 3D prints.

Via ResearchGate