A startup company hopes to deploy a radically new way of 3D printing to existing machines. Topolabs has invented a way to print in three dimensions.

Normally 3D printers perform their work by dividing the intended object into flat layers, or “slices”, which are successively printing on top of each other to form a complete object. This approach is straightforward to develop in software – and ensures that the moving extruder won’t bump into any previously printed material.

But this approach also comes with a variety of limitations.

We spoke with CoFounder James Page, who explained that his frustration with the limitations with layers were overcome by inspiration from nature. He realized that trees “do interesting things to make limbs strong”. It seems that extruding plastic layers is a lot like the internal layers of trees.

The idea is to move the extruder not only in X and Y directions, as is typical, but ALSO in the Z axis: up and down. This means the extruder “floats” around the print, depositing material in unique ways.

Page began working on the concept in the early 2000’s, but assumed someone had already implemented the 3D approach. It was said that Stratasys’ founder, Scott Crump, had even contemplated using this method – but never did so.

Page found that the inexpensive 3D printers that emerged after 2010 provided a platform for deep experimentation on the concept, and by 2013 was “intensely working on it.”

Page and the Topolabs team discovered not only that the 3D extrusion technique is feasible, but that it offered multiple advantages. Parts can be made stronger by extruding directly along lines of stress; different printed geometries are possible. So far they’ve developed four new approaches:

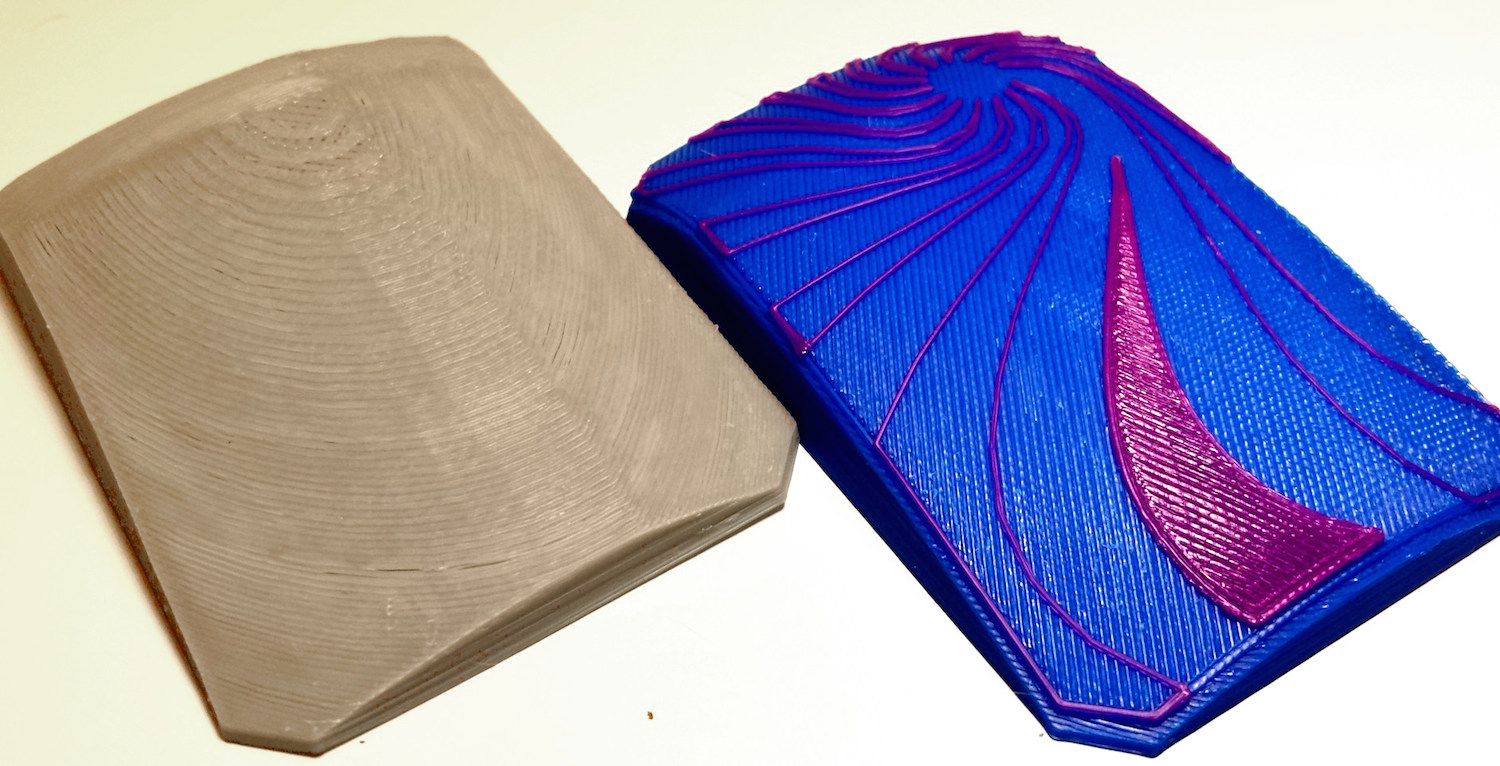

- “Strength Designer” to provide smooth 3D surfaces and gain strength. Check out the difference in the image above

- “Flexible Part Designer” to print mesh-like structures that are flexible like fabric or leather

- “Layer Locking” in which normal 2D flat layers are “locked” together with hooks to prevent layer splits

- “Aesthetics and Line Art” where 2D graphics are interpreted and “wrapped” onto a 3D surface. (also visible on the image above)

These are very powerful functions, indeed. Even better, Page says they have another ten in the labs under development. Layer Locking, yeah, we need that!

It’s not yet available but we understand that Topolabs will deploy the technology as a cloud service. Here’s how it will work:

- Upload your STL to the cloud service

- Select the type of 3D printer you’re using and specify printing parameters

- The cloud service “slices” (if that’s still an appropriate word) your model into GCODE

- You download the GCODE and stick it into your 3D printer

- A true 3D, 3D print takes place

We can’t wait to try out the service, which should launch this year sometime.

Via Topolabs