Additive Industries is set to establish a major presence in California to dramatically enter the US market.

With the recent surge of interest in 3D metal printing, particularly from the aerospace industry, it is not surprising that European and Asian 3D metal printing companies hope to make sales in the US. Additive Industries is one of those companies.

While being quite successful in Europe, they now hope to have similar results in the US, but this requires a significantly greater presence. As a result they’ve decided to not only establish a marketing and sales office, but also a “Process & Application Development Center”. They explain:

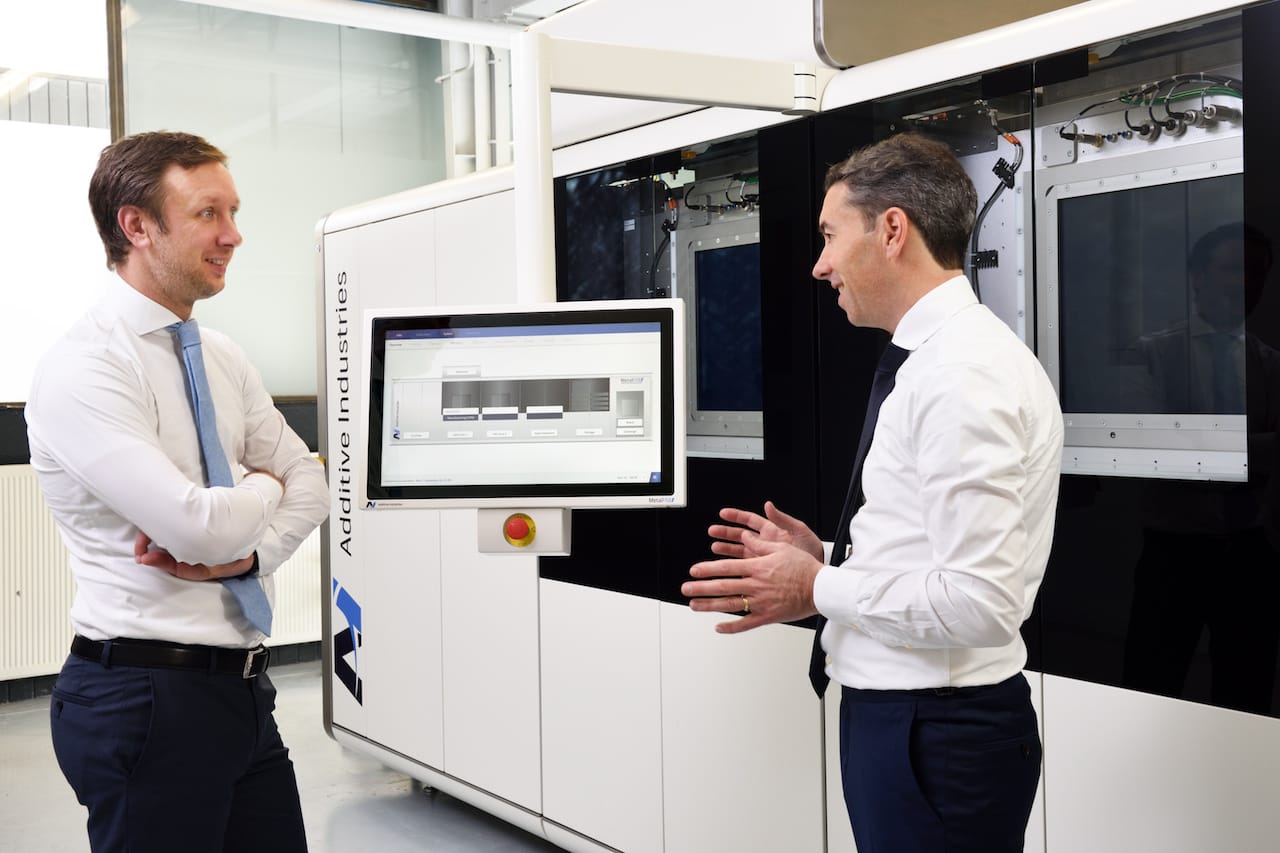

To meet the challenges of the most demanding applications, Additive Industries will establish its new North American Process & Application Development Center within the surging California aerospace and astronautics markets. Realizing time is critical in bringing production 3D printing solutions to North America, Additive Industries hired additive manufacturing veteran Shane Collins to lead the Process & Application Development Center which will be established in Southern California. Additionally, he will build a team of talented metal 3D printing professionals and will be involved in expanding the installed base of the MetalFAB1, industrial metal 3D printing system, in demanding industries like aerospace, automotive and medical devices.

This is very good news for 3D metal printing users in the US, as there will soon be another good option to consider. But I suspect many American 3D metal printing operations are not familiar with Additive Industries, so let’s provide a bit of background.

The company was founded in 2012 by Jonas Wintermans & Daan Kersten in Eindhoven, Netherlands. If you’re not familiar with Eindhoven, it’s a very interesting place and home of Philips, one of the largest manufacturing companies in the world. Philip’s presence in the area eventually led to the founding of large number of manufacturing and service startups, and is perhaps one of the reasons we find 3D printing companies like Ultimaker, Shapeways and now Additive Industries in the vicinity.

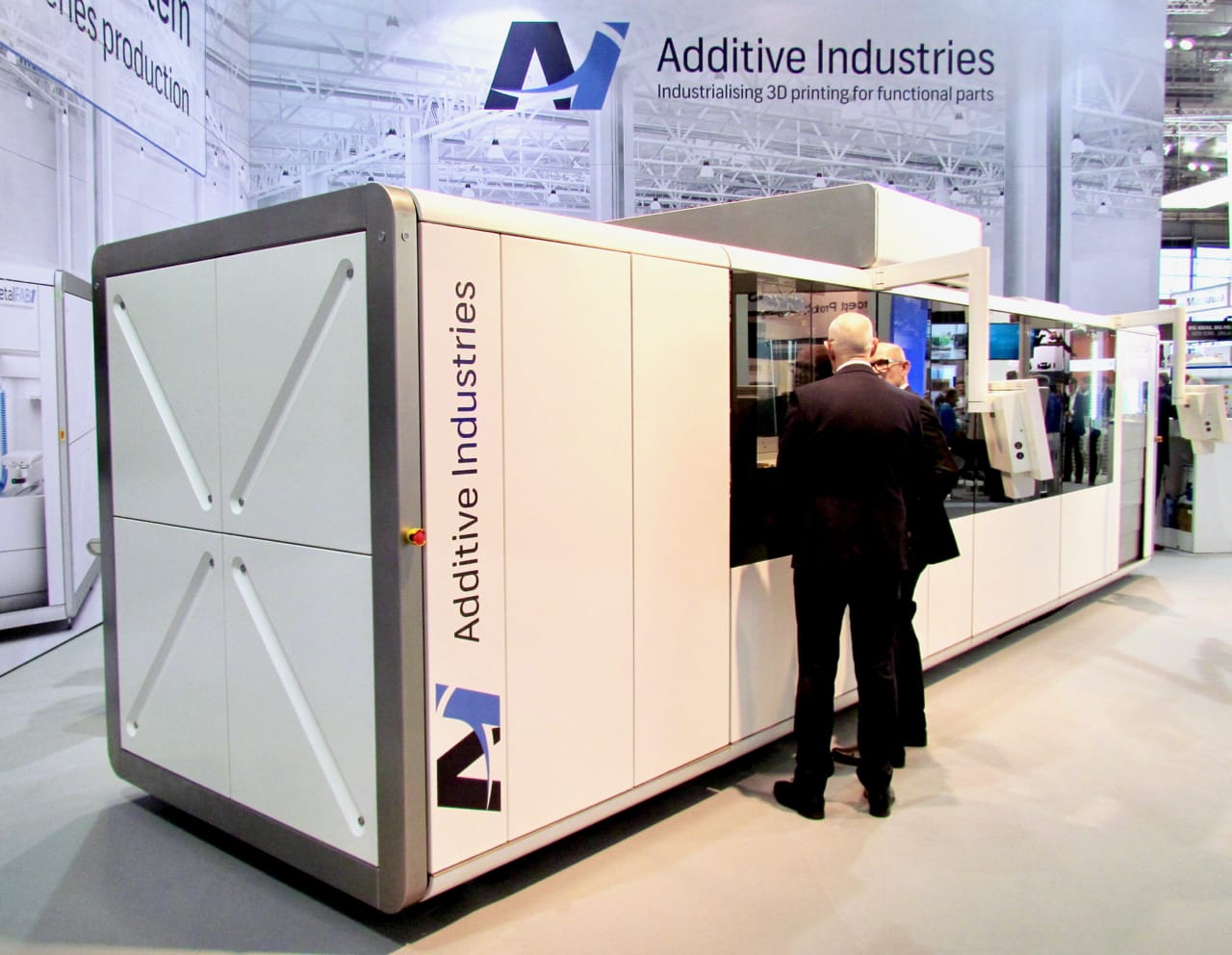

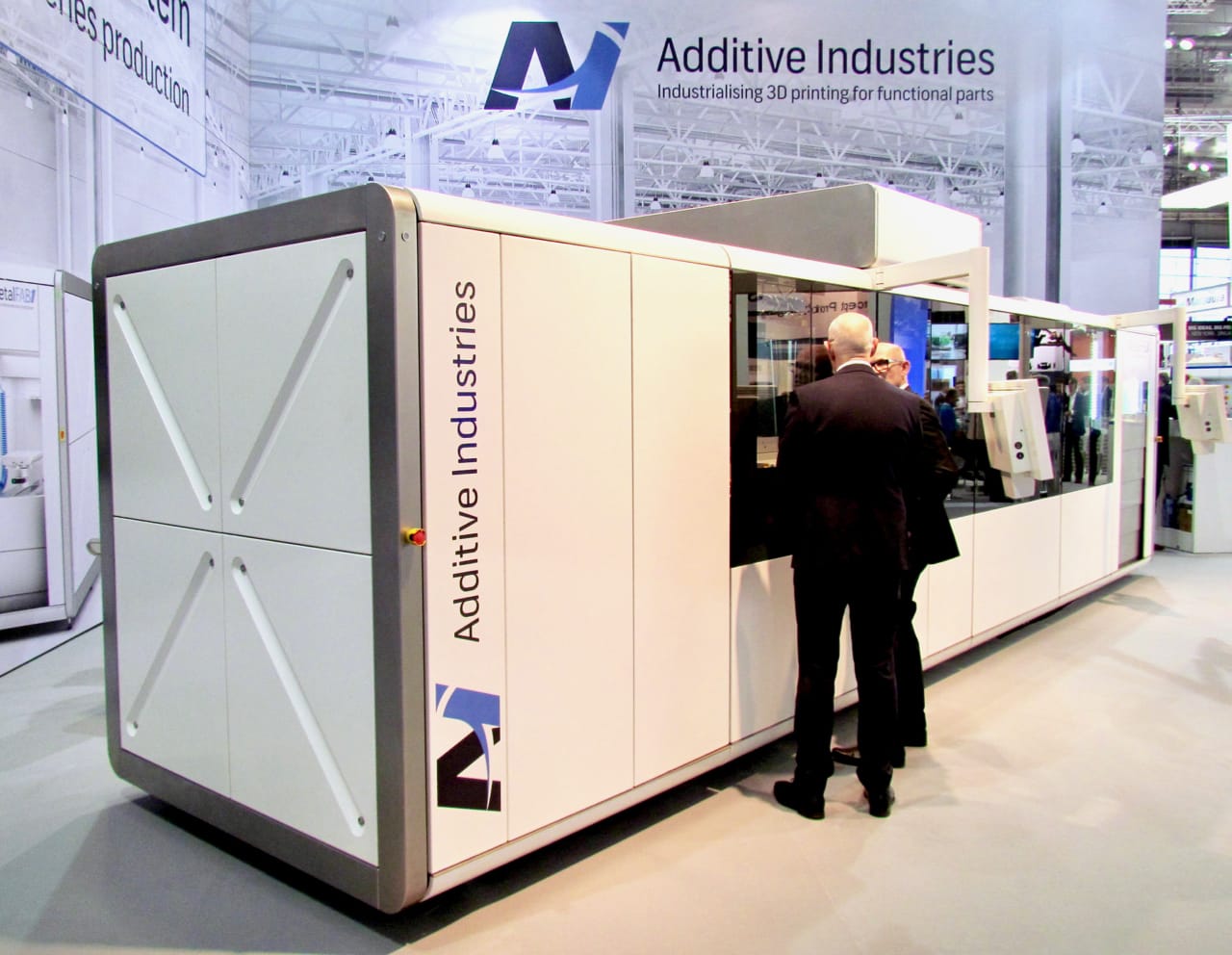

In 2015 after several years of research and development, the company finally unveiled their long-secret project, the MetalFAB1, a 3D metal printing system with a difference.

While most 3D metal printers are essentially standalone 3D printers, the actual process of using 3D metal printing involves a number of steps before and after the actual printing stage. Before printing the metal powder must be sieved and prepared for printing. There is often a requirement for post-printing heat treatment to finalize the crystallization of the print’s material, for example. In many 3D metal printers you must precision slice the print off the metal build plate as well. Depending on the nature of the part being produced, you may also require CNC milling to provide a smooth surface.

And all of this must be done with officially certified processes, equipment and materials to be able to use printed metal parts in aerospace, automotive or medical applications.

It’s not as straightforward as just buying a 3D metal printer.

And that seems to be the mantra for Additive Industries: how can they make the entire process more efficient and effective.

Their solution is the modular MetalFAB1, a rather large unit that is composed of different modules that perform some of these activities in sequence. This means, for example, you can almost immediately move a newly completed metal print to a furnace for heat treatment without suffering warp from cooling that would otherwise occur.

Their system is set up with a strong focus on the entire process of making proper metal parts, not just the 3D printing activity.

Because of this, one could say that the MetalFAB1 system is a production system capable of producing quality parts efficiently.

In Europe, multiple manufacturers have caught on to this concept and have benefited from use of Additive Industries’ solutions. Today they boast of clients include Airbus, Sauber F1 Team, GKN and others.

Now they’re coming to North America.