Austria-based W2P offers a couple of resin-powered desktop 3D printers that offer the possibility of larger high-resolution objects.

The company has been experimenting with the technology since 2013, and launched their first products in April 2016.

W2P (which stands for “Way 22 Production”) markets two models of the SolFlex system, both of which use what at first appears to be the standard “UV light illumination through a DLP projector at the bottom of a transparent resin tank” approach. But there are some interesting differences.

One of the most typically challenges with the tank-bottom illumination approach is that newly solidified layers fuse with the tank itself. This results in a tedious “peel” process to detach the print from the tank bottom, significantly slowing print operations.

Some vendors have developed highly complex systems for dealing with this issue, like Carbon’s oxygen permeable tank, but W2P recognizes the issue and has taken a simpler approach to solving the problem: a flexible, silicone-like tank bottom. This provides very limited adhesion and results in a “quick peel”, They also include a “dynamic peel duration”, making the peel process a bit more intelligent. making prints reasonably fast. We’re told the machines can do 188 layers per hour, but this depends on the geometry of the 3D model being printed.

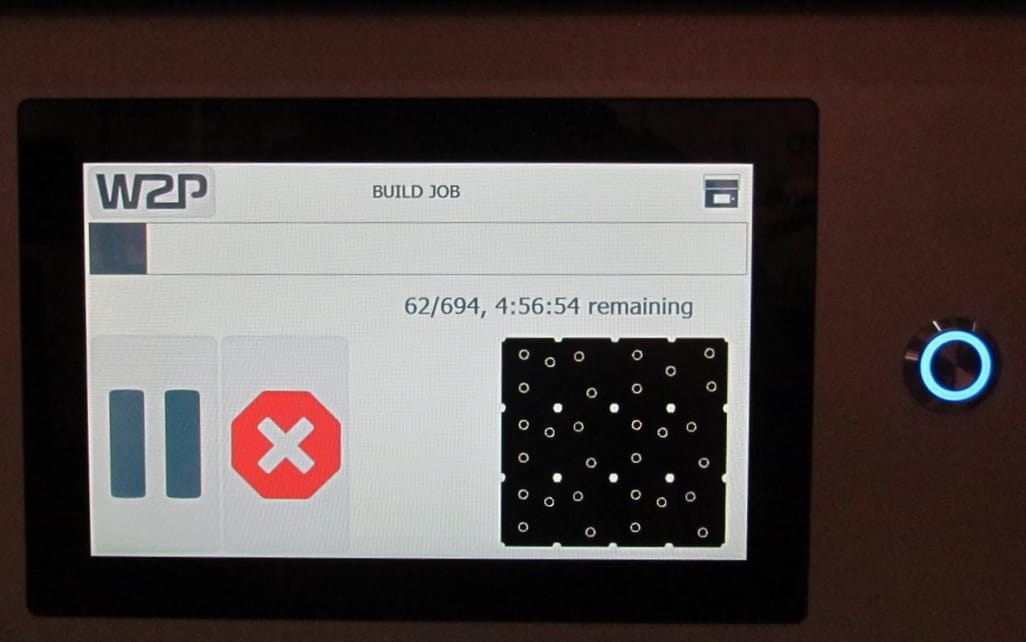

The most interesting feature is what W2P calls “Pixel Stitch”. This feature enables the DLP illumination to “move around” to multiple “zones” on the resin surface. This is how they gain added resolution for large objects.

In most other DLP-powered resin 3D printers, the DLP projection is a fixed number of pixels, say 1280 x 1024, or similar. These pixels are focused on the resin surface and that’s what you get. If you want a finer resolution object, the manufacturer focuses the same number of pixels on a smaller area of resin.

What this means is that typical DLP 3D printers can achieve high resolution only on smaller objects or coarse resolution on larger objects.

That’s not the case with W2P’s system, where the DLP’s pixels are focused on successive areas, leading to a larger printed object with high resolution. In fact, the SolFlex 650 can cover up to six DLP zones in this manner.

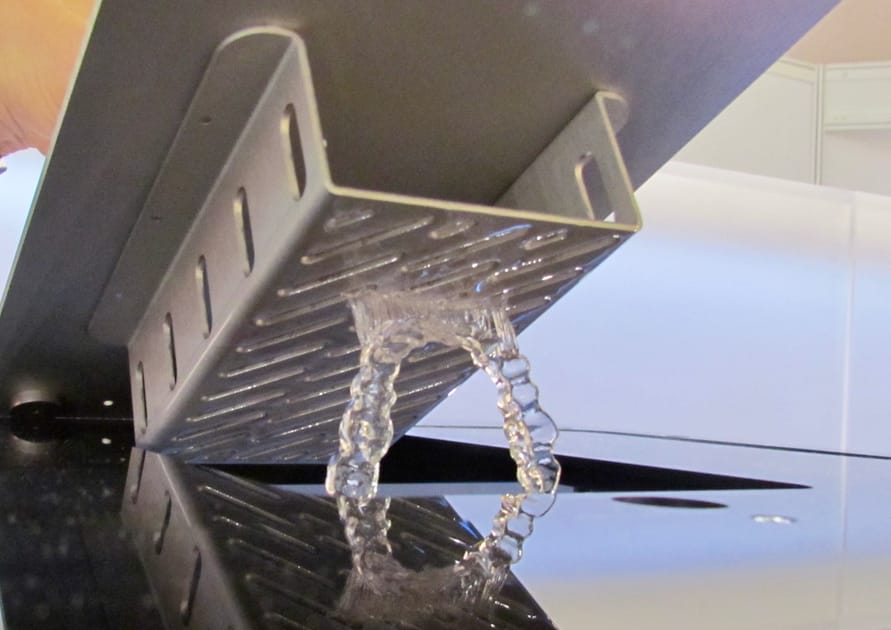

The machines also use a proprietary custom-designed DLP projector, as opposed to an off-the-shelf unit designed for video projection. The W2P projector has a “custom designed light source” that’s specifically for resin solidification (385nm wavelength), and can handle a much wider variety of resins, including transparent resins as you can see here.

The W2P machines are “open materials”, meaning you can use any resin you can find in them, but the machines are “optimized for some materials”. The company is interested in finding any successful settings developed by their users.

The two models offered, the SolFlex 350 and 650 are very similar, but differ in build volume: 120 x 64 x 100mm vs 120 x 128 x 100mm. Oh, and the price is different too: €29K and €35K (USD$31K and USD$37K).

Via W2P