Printing solid objects is pretty easy: you just extrude/fuse/sinter/flash the layers and you’ve got your whatever-it-is-you-wanted. It’s easy because typically these 3D prints are a uniform material all the way through. Occasionally experiments are done with multiple materials and one commercial 3D printer maker (Objet) has a technology that can print mixes of two different materials, but by and large 3D printed objects are pretty simple in structure.

Printing solid objects is pretty easy: you just extrude/fuse/sinter/flash the layers and you’ve got your whatever-it-is-you-wanted. It’s easy because typically these 3D prints are a uniform material all the way through. Occasionally experiments are done with multiple materials and one commercial 3D printer maker (Objet) has a technology that can print mixes of two different materials, but by and large 3D printed objects are pretty simple in structure. This is why Bioprinting is so hard. When you want to print living material, it’s different because live tissue is a machine composed of many different internal parts, working together to maintain life. A key component is, of course, blood vessels. If you were to print a chunk of living cells (and some have done so), it isn’t going to survive very long unless you’re able to deliver life-sustaining nutrients to that tissue via blood vessels and microscopic capillaries.

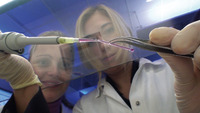

However, researches at the Fraunhofer Institute in Germany have been working on this very issue and appear to have made some breakthroughs. According to Fraunhofer:

3-D printing technology is still too imprecise for the fine structures of capillary vessels. This is why these researchers combine this technology with two-photon polymerization. Brief but intensive laser impulses impact the material and stimulate the molecules in a very small focus point so that crosslinking of the molecules occurs. The material becomes an elastic solid, due to the properties of the precursor molecules that have been adjusted by the chemists in the project team. In this way highly precise, elastic structures are built according to a 3-dimensional building plan.

If such breakthroughs have been made for bioprinting, we’re wondering if these approaches can improve conventional 3D printing by enabling super-high resolution of non-living printed objects?