3D Systems acquired not only a materials manufacturing operation from Huntsman the other day, but also another type of 3D printer: the Araldite Digitalis. We didn’t know much about this device and thought it would be useful to find out more. Perhaps we’ll see how it fits into 3D Systems’ product line.

3D Systems acquired not only a materials manufacturing operation from Huntsman the other day, but also another type of 3D printer: the Araldite Digitalis. We didn’t know much about this device and thought it would be useful to find out more. Perhaps we’ll see how it fits into 3D Systems’ product line.The Digitalis is a resin-based 3D printer, where the resin is cured by exposure to ultraviolet light. This has been done before by other 3D printers, so what’s the twist here? Under the covers the Digitalis has a rather unusual photo-delivery system called the “MLS MicroLightSwitch®”. They don’t use a laser and they don’t use a DLP projector to send pixels of UV towards the resin.

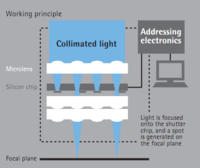

Instead they use a massive print head containing a series of MEMS chips (micro-electronic mechanical switches) that control the flow of 40,000 pixels of fibre-optic channeled UV light. The MEMS opens and closes gates for UV light flow corresponding to the 3D model being printed. The advantage is that the pixels are always delivered perfectly vertically, instead of at an angle as some other systems may do. According to Huntsman, this delivers the “previously unattainable accuracy” of 0.01mm on the XY axes, which is pretty darn good.

Instead they use a massive print head containing a series of MEMS chips (micro-electronic mechanical switches) that control the flow of 40,000 pixels of fibre-optic channeled UV light. The MEMS opens and closes gates for UV light flow corresponding to the 3D model being printed. The advantage is that the pixels are always delivered perfectly vertically, instead of at an angle as some other systems may do. According to Huntsman, this delivers the “previously unattainable accuracy” of 0.01mm on the XY axes, which is pretty darn good. The build envelope is 650mm x 370mm x 600mm, reasonably large. The build speed is quite good, as the MEMS mechanism sweeps across an entire layer in one go, eliminating the need to laboriously trace each curve of the objects being printed. This is definitely not a desktop machine, as it weighs some 2000Kg (2 tons!)

Despite these apparent advantages, the Digitalis hasn’t really gone anywhere since its announcement in 2008. Could this indicate a problem with the technology? Or perhaps marketing difficulties? (Huntsman is a chemical company after all, not a 3D printer manufacturer.) The big question is where 3D Systems will take the Digitalis. Will it become yet another model on their extensive line of 3D printers? Will its technology be incorporated into other devices? Or will it simply just fade away?

Via 3D Systems and Design World (Video)

aside from the fact that it has not yet been heavily marketed, the earlier introduction did not seem to have gotten a good market timing. it simply got covered up in the pile and needs a little grooming to sell out.

aside from the fact that it has not yet been heavily marketed, the earlier introduction did not seem to have gotten a good market timing. it simply got covered up in the pile and needs a little grooming to sell out.