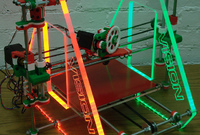

Manufacturing engineer Matt Underwood’s Kickstarter project is the Vision 3D printer. Yes, it’s another RepRap variant, but with quite a few interesting improvements.

Manufacturing engineer Matt Underwood’s Kickstarter project is the Vision 3D printer. Yes, it’s another RepRap variant, but with quite a few interesting improvements. Underwood observed that while many inexpensive 3D printer kits are available they are typically difficult and time consuming to build, making them beyond the reach of non-technical mortals. He set out to design a 3D printer that could be more easily assembled and still maintain an inexpensive price. The result was the RepRap-derived Vision 3D printer and a Kickstarter project to gather up initial funding.

The project lists a large number of enhancements over the basic RepRap design and we thought these were the most intriguing factors:

- No soldering required

- All tools included

- Choice of case material and color

- Z-layer adjustment screw for easy configuration

- Heated bed to reduce warping

- 150 fewer parts than a standard RepRap

- Improved belts and pulleys to improve resolution

- Vibration pads to reduce operating noise

- Integrated LED lighting

- Pre-assembled extruders

- More rigid design

- Some pre-wiring completed

At this point Underwood is miles past his original goal of USD$25,000, so we offer congratulations on starting a new business! But it’s not too late to participate, as the funding round is still open until June 28th. Until then you can pledge an amount and receive one of several rewards ranging from USD$5 to USD$2100, with the basic kit available for USD$725.

Via Kickstarter