Concrete 3D printer D-Shape has been awarded first place in NYC’s “Change the Course” Waterfront construction competition. The USD$50,000 prize is intended to generate unique ideas and approaches for redeveloping the 565 miles of NYC shoreline, particularly after damages incurred by Hurricane Sandy.

D-Shape’s technology will be used to restore damaged seawalls other other edifices by scanning, remodeling and then 3D printing concrete. The NYC press release says:

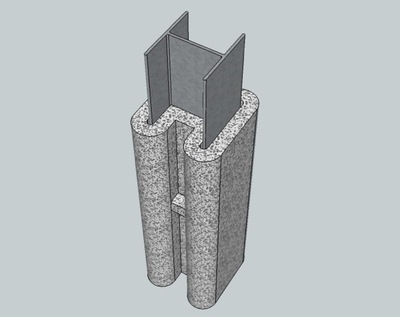

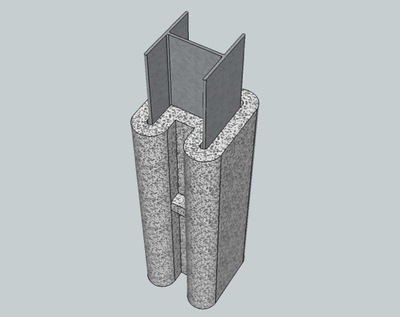

The advantages of quality control in fabricating off-site yet being able to closely fit the encasements, blocks or extensions to the surface that they are nestled into has a number of advantages, including lower costs, better quality control (thus longer life), lower labor mobilization and quicker delivery and installations. Furthermore, there is a potential opportunity to rejuvenate the waterfront by letting artists leverage the total freedom of design to add an aesthetic touch without a significant added cost.

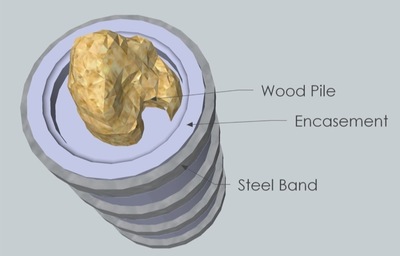

How much savings could be achieved with D-Shape’s approach? They estimate a staggering USD$2.9B! They’ve developed an approach for scanning individual decaying piles and 3D printing custom fittings to secure them for the future. If that sounds like a lot of work, it is – but it’s far less than solving the issue with traditional approaches.

If NYC proceeds, this could be one of the biggest boosts to a 3D printing startup in history. Certainly it would permit the construction of several concrete 3D printers, which, after completing NYC’s waterfront, could be used to print a great many other exterior structures worldwide.

Via NYCEDC