In almost every 3D printer we’ve seen, even those with multiple heads, only one print head is actually used at a time. First you print the model material, then you print support material, layer by layer, one extruder at a time. But now that’s changed.

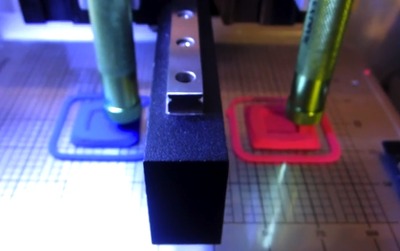

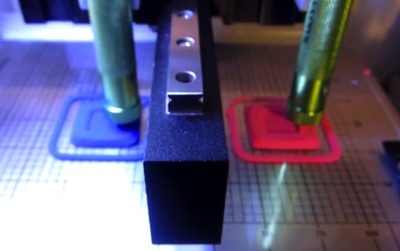

HYREL, notable for 3D printing clay, Sugru and other squishy substances, now offers a way to print multiple objects simultaneously. In other words: More than one extruder is active during printing. Don’t believe us? Check out this video:

Evidently the HYREL 3D printer can manage up to four extruders simultaneously. While it’s obvious each extruder must perform the same motions, it means that up to four identical copies of an object can be produced in the time it normally takes to produce one.

This is a very significant speed advantage, something quite important as the slowness of 3D printing is one of the technology’s major drawbacks.

Could other manufacturer’s machines accomplish this feat? Perhaps, but extra extruders means more complexity and more cost. Somehow HYREL has done it.

Hm, does HYREL have a patent for this approach?

Via HYREL

My understanding is that this has been possible for a while with a dual extruder Replicator and Sailfish firmware.

There's a "ditto" mode that runs both extruders simultaneously to produce the same object twice.

My understanding is that this has been possible for a while with a dual extruder Replicator and Sailfish firmware.

There's a "ditto" mode that runs both extruders simultaneously to produce the same object twice.