A report from Michigan Tech details the results of a study that attempted to determine the “greenness” of 3D printing. Their result: 3D printing is apparently significantly less energy-absorbing than conventional mass production.

You wouldn’t think so at first, because mass production is clearly a more efficient process due to the economies of scale. However, the study pointed out that:

- Shipping mass manufactured goods half-way across the globe consumes a significant amount of power; producing goods locally reduces that element

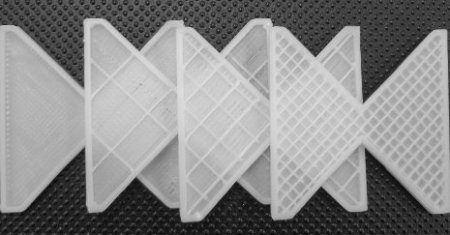

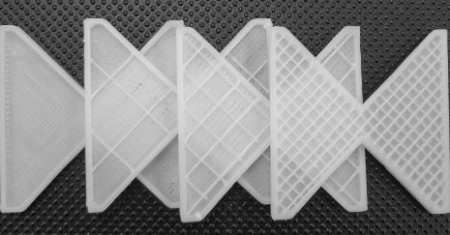

- Mass manufacturing typically uses subtractive manufacturing, where significant material is wasted; 3D printing is an additive process that uses (mostly) only the material required in the final object.

Specifically, the study found home 3D printing to be 41 to 64% less energy absorbing than conventional approaches. They analyzed the usage with ABS plastic as well as the recyclable PLA material, which reduced energy use even more.

We have a couple of thoughts on this:

- If the mass manufacturing occurs closer to the site of usage, as opposed to across the sea, how does the energy equation change? Is 3D printing still a greener alternative?

- How would a 3D print service fare in this analysis? The items are produced without waste but do incur shipping charges.

The answer to future manufacturing is obviously complex and will take years to settle into any new paradigm. Nevertheless, it is now clear there are green solutions that can become part of our future.

Via Michigan Tech