Soon to launch will be Structr3D Printing’s “universal paste extruder” that could enable many personal 3D printers to extruder some very unusual materials.

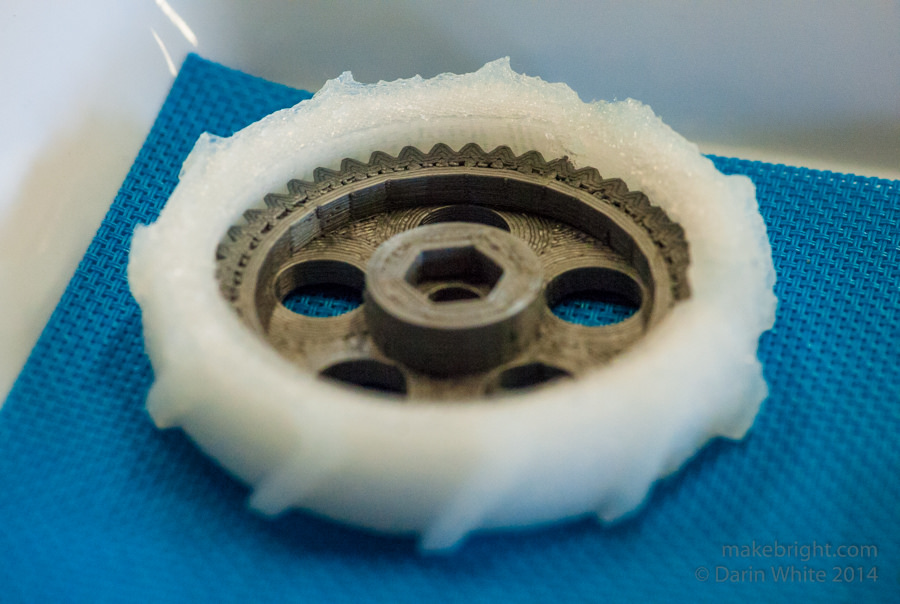

It’s not a 3D printer per se, but rather a carefully designed extruder attachment that can, in theory, be mounted on many 3D printers by replacing the extruder. The technology is syringe-based, which has been used previously. The difference here is that the extruder is designed for easy installation and use of many different materials.

The extruder uses 60cc syringe cartridges, which contain virtually any paste-like material. Extrusion occurs in the same manner as conventional plastic filament-based 3D printers – even using the same driver software, but with very different printing parameters. The team has tested a wide variety of different materials, including Silicone, Icing Sugar, Wood Filler, Polyurethane, Latex and “many more”. As you might imagine, these materials offer significantly different properties including flexibility, stretchability and even edibility.

We think this is a great idea, as 3D printer operators will certain be interested in access to an almost unlimited amount of unusual materials. Even better, these materials are obtainable at far less cost and much easier access than materials required for conventional 3D printers. Icing sugar is likely in your kitchen cupboard already, while many others can be found at the neighborhood hardware store.

In the future it is likely that the team could partner with one or more 3D printer manufacturers to include the extruder as a standard feature on certain machines. For now, you’ll have to wait until their crowdfunding campaign launches soon.

But we do have some concerns that are probably being considered by the Structur3D Printing team.

The wide variety of materials implies a large number of printing parameters. How fast should you extrude latex vs. peanut butter? While this may be determined through lengthy experimentation, we expect Structur3D Printing to provide a comprehensive “recipe database” to simplify life for 3D printer operators.

Another concern is safety. Since the extruder is capable of using edible materials, best practices for food safety must be practiced. This would include careful washing of used cartridges – and any food-exposed portions of the extruder – before reuse, or using food cartridges before they go bad.

Nevertheless, it is a good step forward for the 3D printing community, who can now gain the ability to 3D print a much larger set of useful objects.

Including lunch.