Following up on our piece about the 3DPrintTech free utility for segmenting large 3D models for printing, we found something.

To recap, 3DPrintTech can take a CAD model and automatically chop it up into printable sub-models – with connectors – that can then be printed on your 3D printer. While it sounds good, the utility only works with certain expensive CAD programs. So what are the rest of us to do?

We hoped for a utility targeted at personal 3D printer owners, but couldn’t find one. There may indeed be such a beast, we gave up looking. We did, however, find a scientific paper exploring the concept.

“Chopper” was a prototype tool built experimentally by researchers at Princeton in 2012. They say:

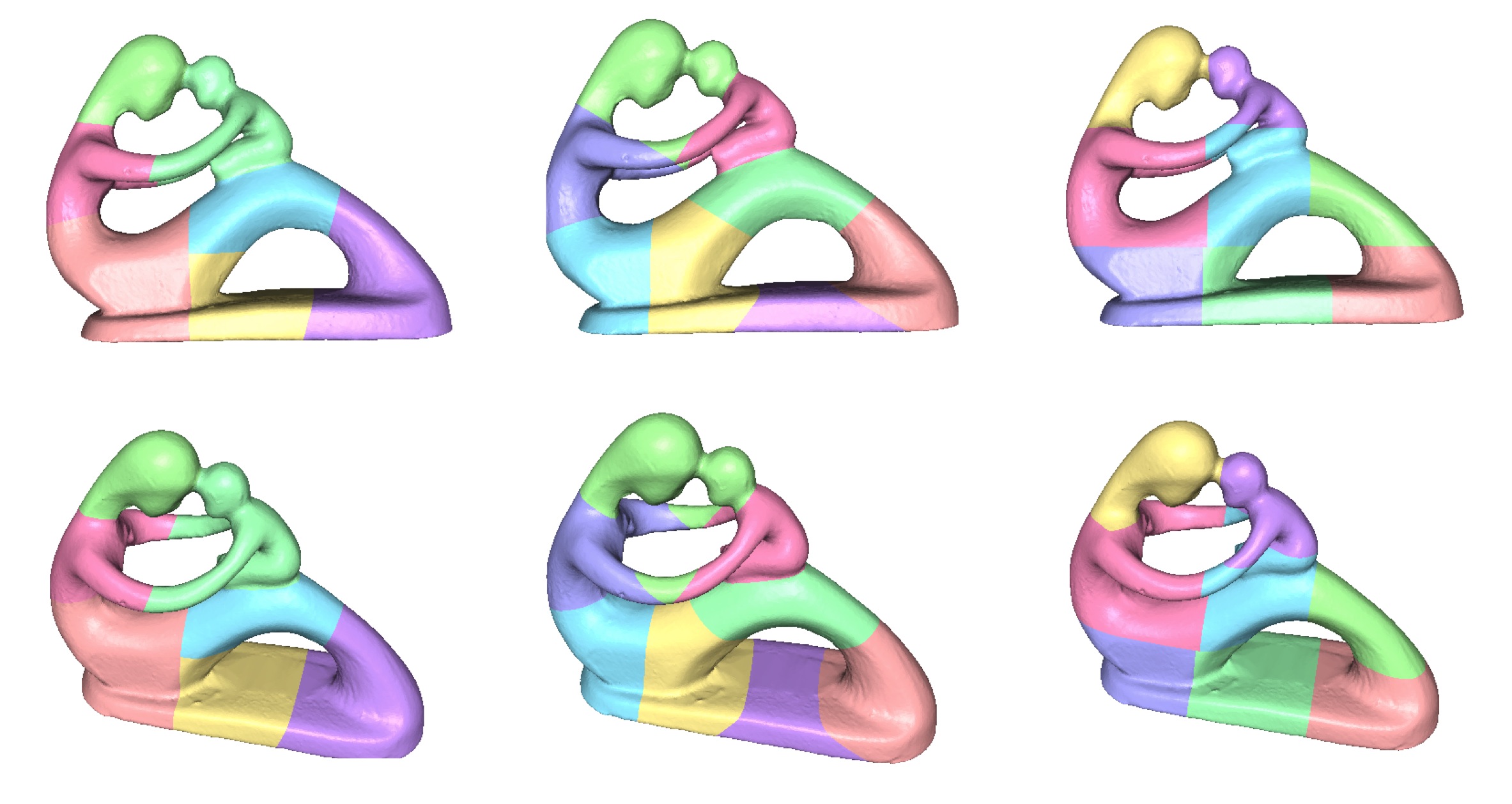

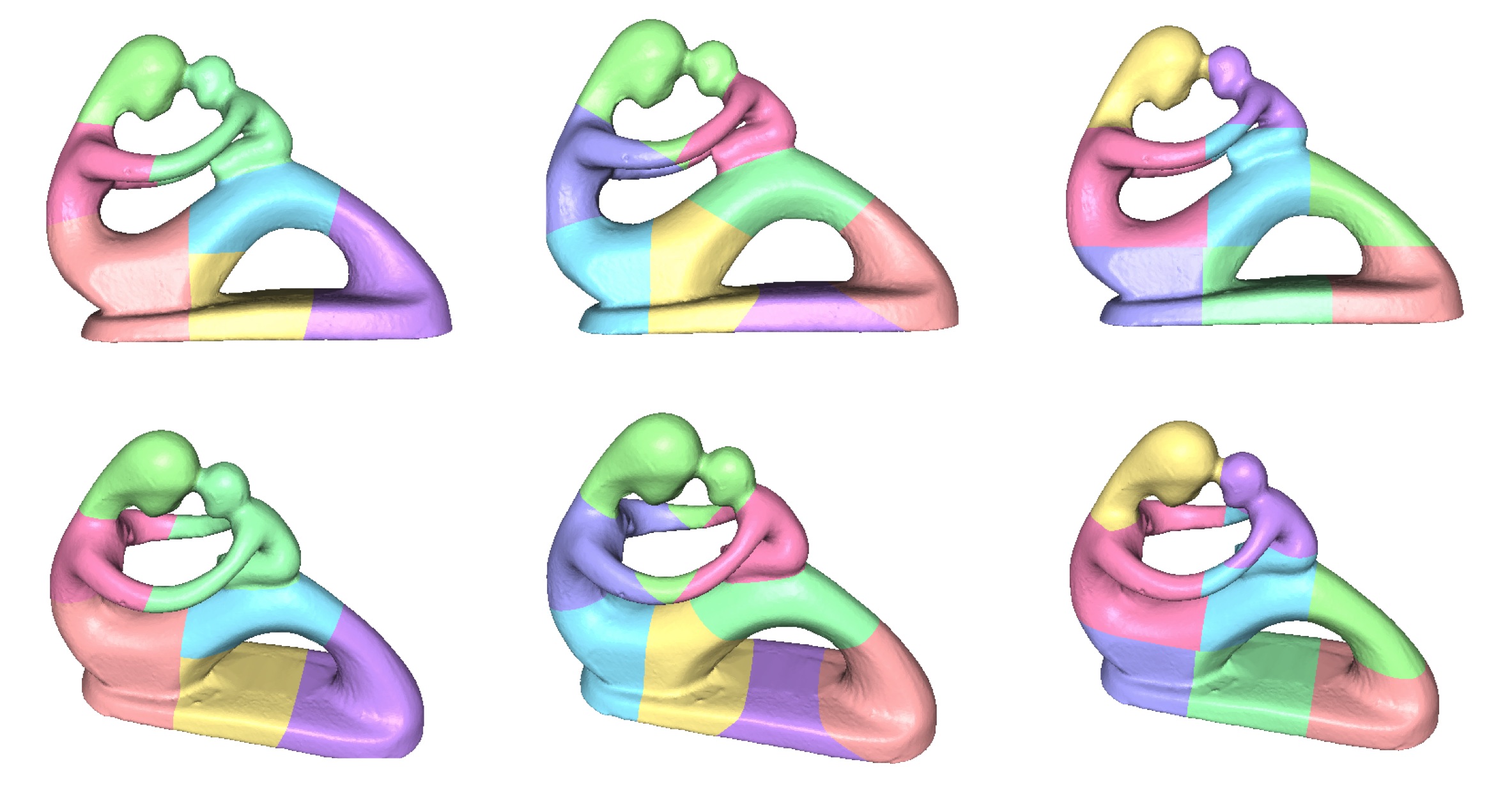

We propose a framework, called Chopper, to decompose a large 3D object into smaller parts so that each part fits into the printing volume. These parts can then be assembled to form the original object. We formulate a number of desirable criteria for the partition, including assemblability, having few components, unobtrusiveness of the seams, and structural soundness. Chopper optimizes these criteria and generates a partition either automatically or with user guidance.

It sounds complicated because it is. If you bother to read through the paper, you’ll find they explored a number of critical dimensions, all of which must be dealt with correctly in order to effect a proper segmentation. They looked at:

- Printability: the parts must fit inside the working volume.

- Assemblability: it must be possible to put parts together (without interference) into a finished model.

- Efficiency: the partition should avoid small parts and, in general, minimize the number of required sub-volumes.

- Connector feasibility: each interface must be large enough to admit connectors, protrusions, or other aids to assembly.

- Structural soundness: parts should not have thin slivers, and seams should be away from areas of high mechanical stress.

- Aesthetics: seams should be unobtrusive, detracting from appearance as little as possible, and should follow the natural symmetries of the model.

The prototype evidently accomplished all these, using sophisticated mathematics to balance all factors. The paper shows multiple examples of relatively complex structures being successfully chopped up into printable pieces.

Alas, all we can find is the paperwork, but no usable software. Perhaps the concepts developed in the paper can be translated into a tool usable by everyone, but from the looks of the method, it will be challenging.

Via Princeton