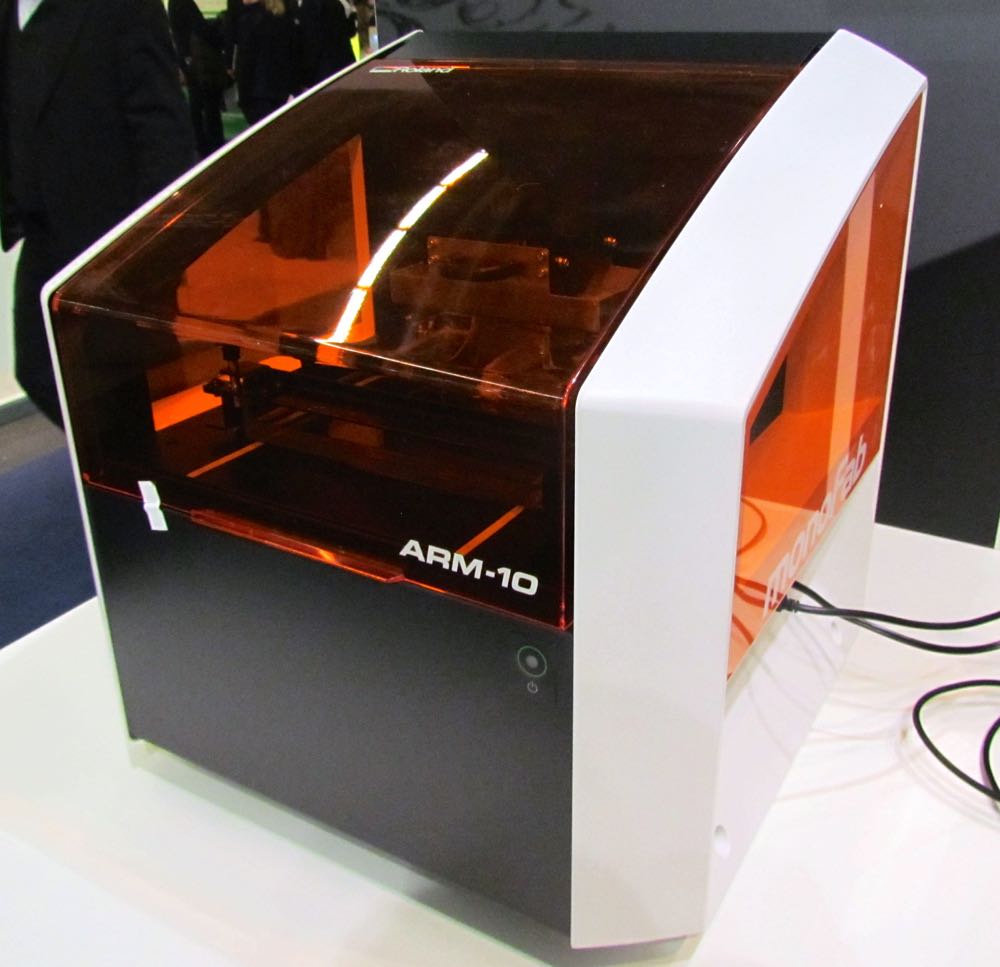

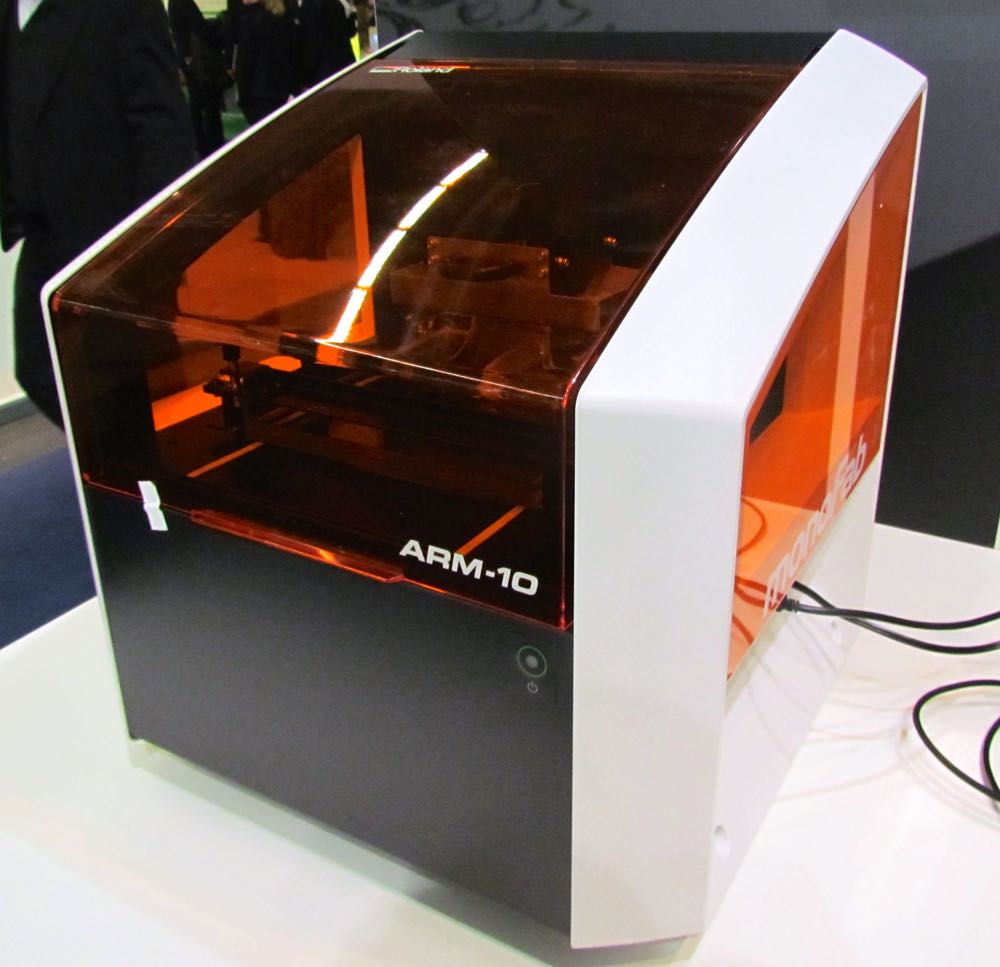

We had a look at Roland’s new twin machine prototyping solution they call “monoFab”.

It’s a series of two different rapid prototyping machines. The ARM-10 provides desktop 3D printing capability, while the SRM-20 provides desktop milling functionality. The two machines together can provide a serious prototyping capability for any small workshop.

The ARM-10 is a DLP-powered resin 3D printer, meaning it is capable of printing at pretty high resolution. Using photo curable resin, the DLP light engine repeatedly cures 0.01mm layers in its 130 x 70 x 70mm build volume. Currently they supply only one resin for the printer, a semi-transparent polypropylene-like product they call “ImageCure”. However, they say any resin can be used, enabling third party solutions. This is apparently Roland’s very first 3D printer, but they tell us to expect more in the future.

The other machine in the monoFab family is the SRM-20 milling machine. This device is capable of milling light materials, including “Modeling Wax, Chemical Wood, Foam, Acrylic, Poly acetate, ABS, PC board” at up to 7,000 rpm.

The 3D printer is priced a bit higher at USD$5,995, while the mill is set at USD$4,995.

Via Roland