This week’s selection is Daren Banarsë’s beautiful and functional 3D printed Melodica.

Before we go further, let’s talk about Melodicas. They’re a handheld, air powered musical instrument that incorporates a keyboard, such as you’d see on an accordion, but operates like a flute.

London-based artist and composer Daren Banarsë began his Melodica journey with an inexpensive toy melodica, with which he fell in love with the instrument and its portability. However, it wasn’t all peachy. He explains:

At first it was great fun, and quite a novelty to be playing a toy instrument to a high standard. But it had its drawbacks. You couldn’t play fast melodies without some of the notes dropping out, and the tone was so shrill, I felt sorry for anyone sitting next to me. But perhaps worse of all, I found it difficult to be taken seriously at music sessions when I pulled out a bright plastic instrument which was ultimately designed to appeal to kids.

To solve the problem, he turned to 3D printing, a technology he did not know much about at the time. Learning basic CAD software at first, then carefully disassembling the melodica to discover its inner workings – and design replacement parts to bring the device up to par with his expectations.

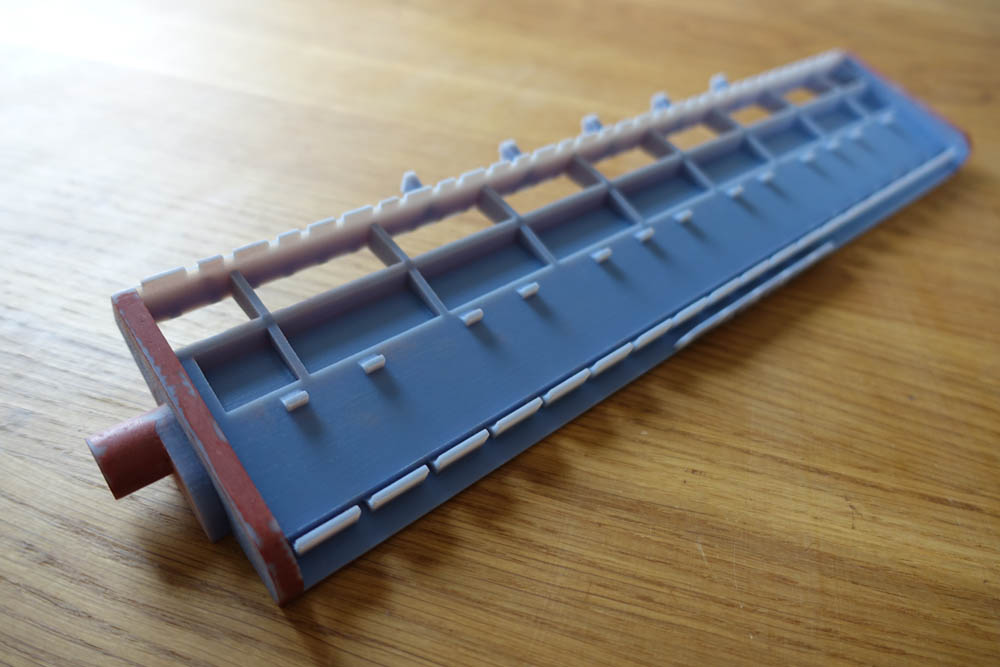

However, 3D printing the newly designed parts on his FlashForge desktop 3D printer proved insufficiently accurate to be used for producing the precise audio required. The next step was a much higher quality 3D printer. A first attempt used a Stratasys Objet Eden 500V, whose printed parts proved too flexible for the application. Banarsë then moved on to printing the parts and frame in Nylon-12 at Shapeways.

The next challenge was the porosity of Nylon-12; the airtight frame of the melodica wasn’t, so Banarsë applied several layers of acrylic sealant, which did the trick. Finally, the instrument was working perfectly – but it didn’t really look and feel like a traditional instrument.

Once it was all working properly, it was time to turn it into an organic looking instrument that would look at home in a professional environment. So I carefully shaped some wood to fit on top of the black keys, and made some end pieces to give the instrument a traditional feel. I also stripped the ivory from some old piano keys to recreate the touch of a quality instrument. And I’m delighted with the result. I finally have a musical instrument that I can take out and play at professional concerts and recordings, and it looks just as good as it sounds.

And so ends the story of the world’s first 3D printed melodica. But not really – Banarsë writes music and creates musical sculptures under the pseudonym Troy Banarzi. His music has been featured on such programs as The Apprentice, Top Gear, Horizon and Coast.

Next time you hear a melodica on a video, it just might be 3D printed.

Via MelodicaWorld and MelodicaWorld