Faculty from the Warwick Manufacturing Group (WMG) and the Warwick Medical School at the University of Warwick in the UK are working in collaboration with art historians from the University of Cambridge.

Their goal: to determine the design and construction process of two curious Renaissance bronzes.

The team has been utilizing neutron imaging, x-ray fluorescence (XRF) analysis, 360-degree laser scanning, 3D printing and real-time x-ray videography to assess why the thick-walled casts are losing the intricate detailing and sophistication of the original models.

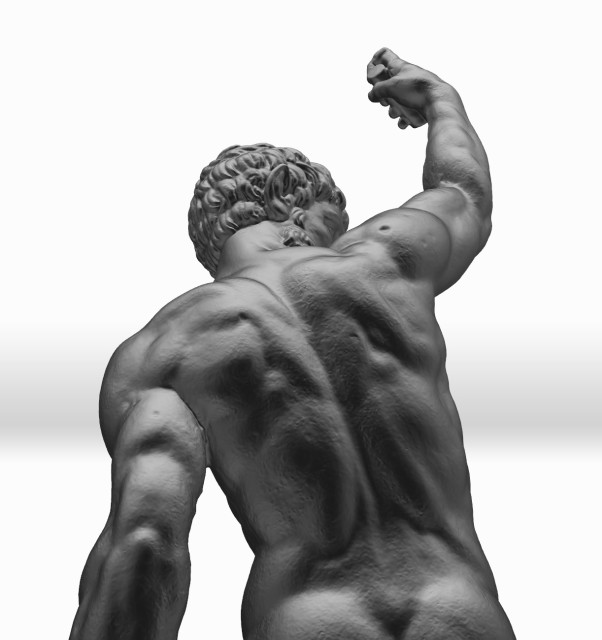

The two bronzes, held at the Fitzwilliam Museum in Cambridge, first came to the world’s attention in February of 2015, when a group of experts asserted they were actually cast models by Michelangelo.

The museum brought in sculptor and archaeometallurgy expert Andrew Lacey to help construct one full-size and two reduced-scale replicas of the bronzes. To do this, Lacey used the traditional method of spruing for one of the scale models while using a more unorthodox method for the second, which he believes was used for their creation.

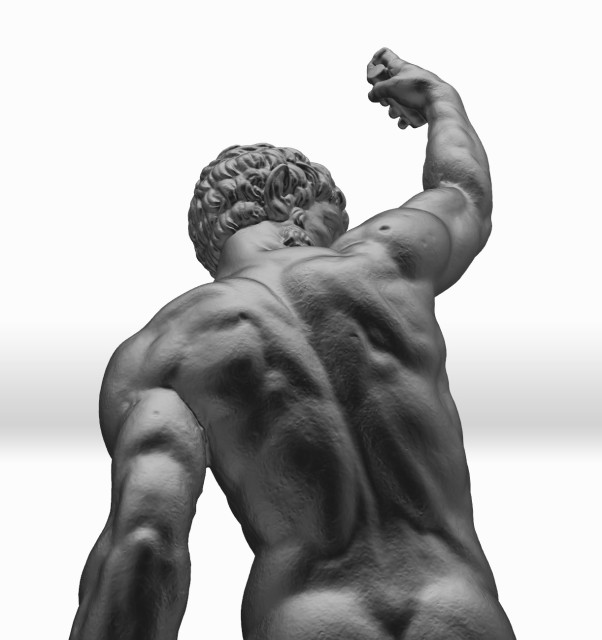

Lacey will be assisted by the WMG researchers, who will be providing high-resolution 3D scans of the bronzes and by Warwick Medical School professor Peter Abrahams, who will comment on their anatomy.

Read more at ENGINEERING.com