A common misunderstanding by newbie 3D print folks is that objects are printed completely solid. In fact, we believe that many prints should be hollow!

The misunderstanding likely arises due to the familiarity of objects produced with injection molding, which produces solid parts, meaning the inner portions you don’t see are 100% material. This is not a requirement of 3D printing, where you can usually specify a density factor.

You can, for example, print an object at 50% density. This produces an object with great strength but with far less use of consumable material. In other words, cheaper. It’s also faster to print, since fewer extrusions need to take place.

But you can also specify “0%” as your infill density. In other words, completely hollow!

We are quite fond of printing hollow objects when the usage is appropriate. Appropriate usage, in our view, means the object does not undergo any mechanical stress – it simply sits there and looks nice. If you require an object that’s part of a machine, say, or otherwise is to be pushed, bent or twisted, then you’d best forget about printing hollow objects and determine the optimum infill density for your application.

In any print, the infill typically provides either overall strength to the object, or interior support for higher layers that would otherwise be problematic overhangs during printing.

In many cases, however, the geometry of object may not require any interior support and printing hollow becomes feasible. You’ll just need to increase the number of exterior shells (perimeter wall thickness, in some terminologies) to shore up the object strength.

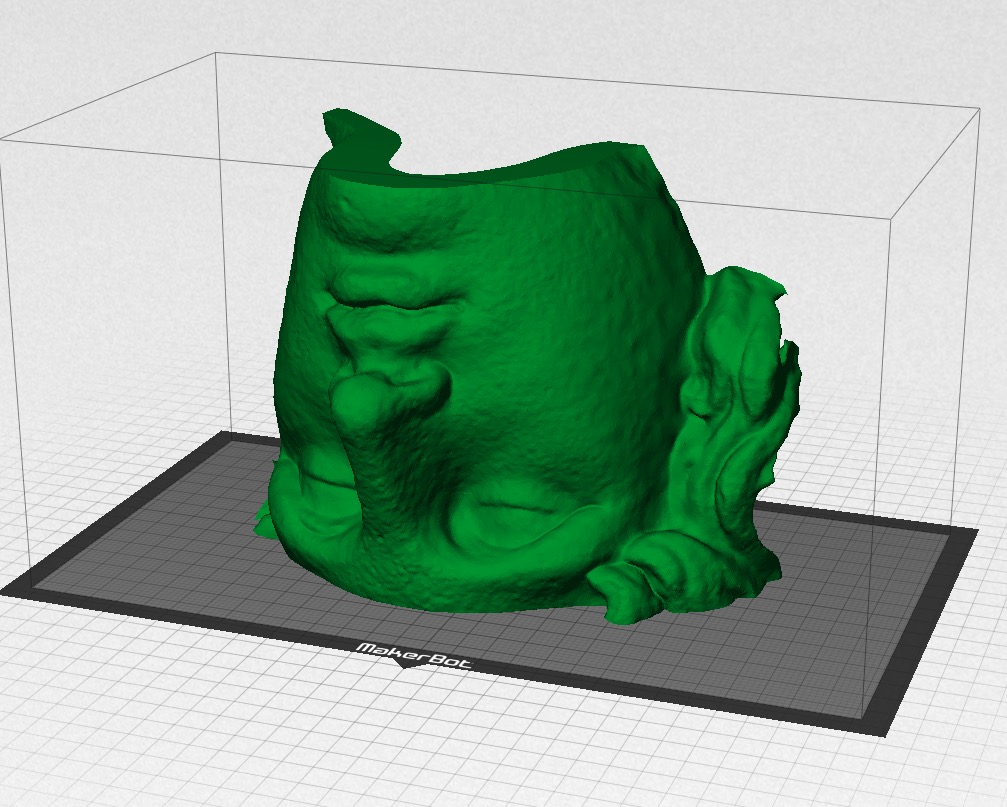

This approach, while not feasible for every print, is often quite usable. The benefits are quite dramatic: print times and material use can be hugely decreased. Consider this example print we recently sliced (image at top):

- With 100% density, 2 shells: 27:08 print time, 527g material

- With 50% density, 2 shells: 14:30 print time, 269g material

- With 10% density, 2 shells: 8:19 print time, 145g material

- With 0% density, 3 shells: 6:26 print time, 120g material

As you can see, there is a dramatic effect when choosing “hollow”: the hollow print was 4.2x faster and required 4.4x less material. Our advice: take a close look at your model, and if it’s not being stressed, see if you can print it hollow. If you can’t, you can also consider simply reducing the percentage of infill to the absolute minimum required for successful printing.