Origin Laboratories promised to go into beast mode. They sold the idea that they could guarantee the authenticity of a line of Beast Mode footwear with an electronic tag, but now they had to produce it.

The cool shoes, inspired by Seattle Seahawks star running back, Marshawn Lynch (a.k.a. Beast Mode), were created by footwear company, Greats.

Contemplating his meager options from a small, already expensive office space near downtown San Francisco, Chris Prucha, CEO and co-founder of Origin, may have been having visions of getting stomped by Lynch going beast mode on his head after failing to deliver.

A small office near downtown San Francisco is not the place to set up an injection molding facility. Prucha’s go-to production service, Proto Labs, left a lot to be desired in terms of finish quality. To get the quality he needed in an industrial 3D printer, it would cost in the neighborhood of $100,000, and still would require an assembly area.

But didn’t Autodesk, right down the street, come up with Ember, a relatively low-cost industrial 3D printer? Was it industrial grade? The software that ran the $7,500 Ember was open source. Maybe it could be programmed for operations that could automate assembly steps.

As luck or fate would have it, the Ember would prove to be an ideal machine for Origin to produce a series of customized near field communication (NFC) tags for each pair of shoes in a largely automated assembly-line fashion. The strengths of the Ember in this process were two-fold: the speed and resolution of the system’s digital light processing-stereolithography (DLP SLA) process and the open-source nature of its design. Autodesk’s desktop 3D printer is capable of achieving layer thicknesses of just 10 microns and a resolution of 50 microns on the X- and Y-axes. This can be performed at speeds of roughly 18 mm/hour, allowing the Origin team to produce near-injection mold quality at a high throughput.

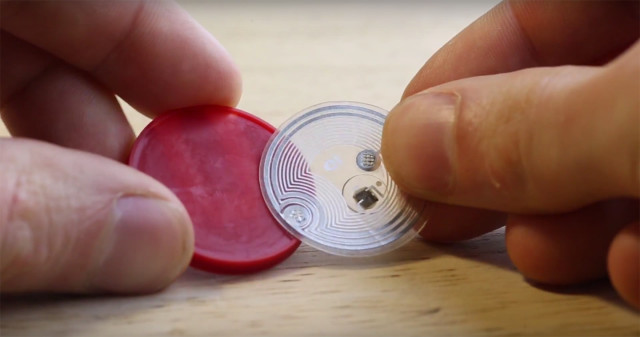

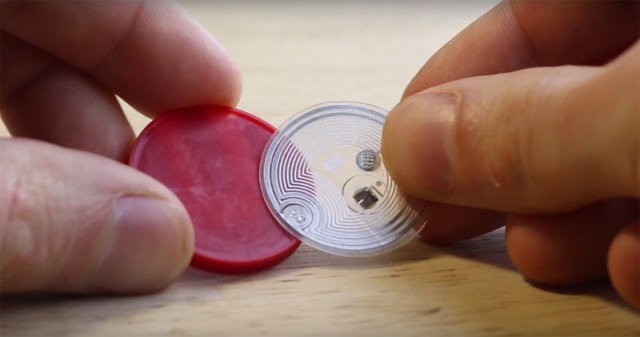

More importantly, everything about the Ember is open source, from its software to the design of the machine itself, all of the way down to the formulations of its resins.This gave the Origin team the ability to customize the 3D printer to their needs, resulting in a workflow that would allow for the series production of their custom NFC tags.To do so, Origin created a custom 3D printing procedure that saw the Ember pause during the fabrication process.After 3D printing the initial layers of the tags, the printer would stop so that the radio-frequency identification (RFID) chips could be inserted into the prints.The print would then continue, sealing the chip inside.

Read more at ENGINEERING.com