A research paper by engineers from Netherlands-based Arup suggests that 3D printed building elements could provide significant benefit when designing particular structural styles.

Specifically, their work focused on “tensegrity structures”. These are buildings or structures that are made from a series of cables or other features arranged to provide “continuous tension” to create the structure and its strength.

Such structures are typically dependent on the “nodes” that connect the pieces of the structure that carry tension. Often these connectors are each unique as they must carry different loads from different directions. Production of them is challenging, as you might imagine.

The research paper compared standard methods of production with unique 3D printed versions.

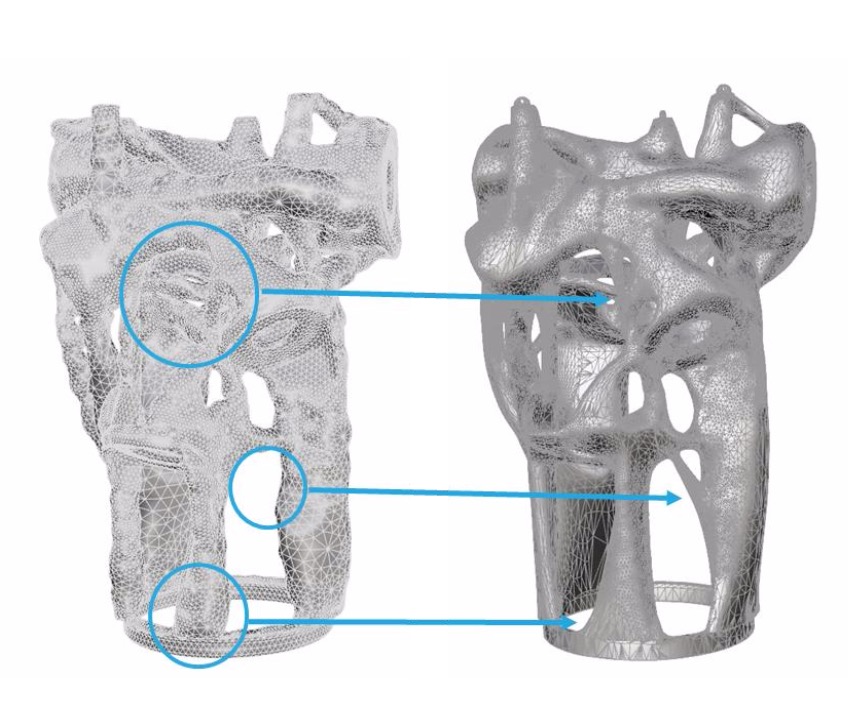

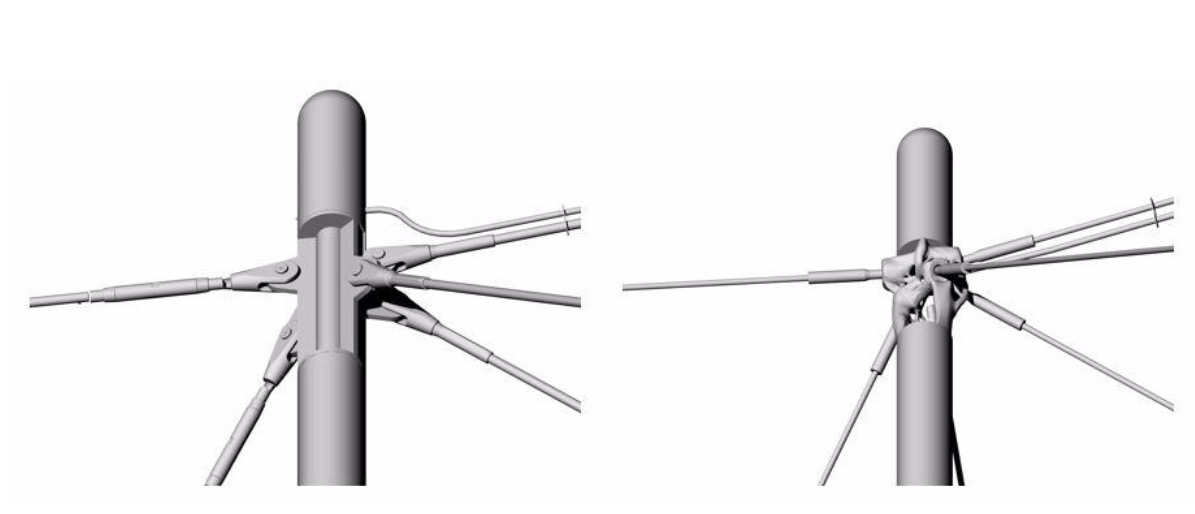

Here you can see a comparison between the standard connector and two produced with new 3D designs, with the most advanced one on the right. There is quite a difference in size, obviously, but it turns out there’s a lot more to it.

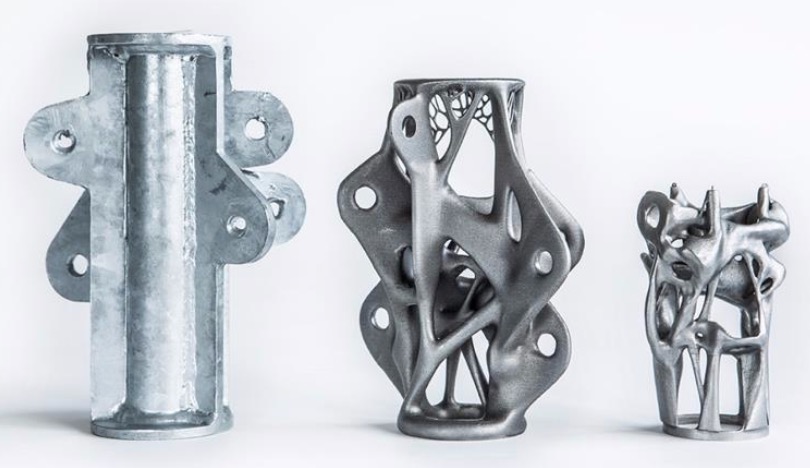

Here we see a stress analysis of each, and it’s clear the new design is not only more efficient in terms of material, but also performs much better.

However, due to the current costs of 3D printing in metal, the cost of these advanced parts still exceeds those made in the traditional manner.

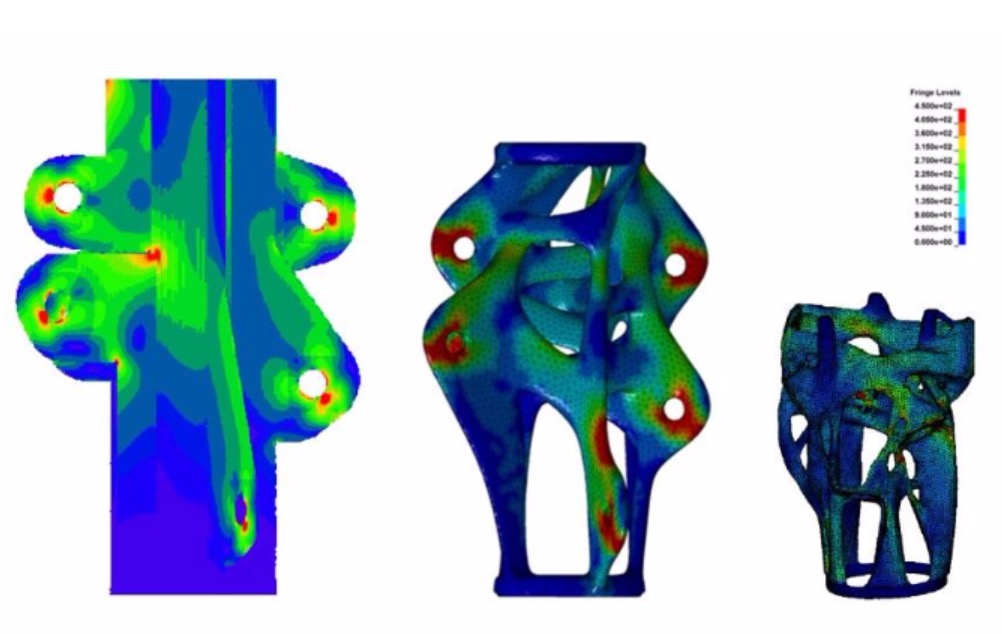

Here’s how it could look deployed in a tensegrity structure.

The paper concludes:

Only with this new iteration we realize how close we still were to the traditional design regarding shape and design approach. This time we allowed ourselves to completely revise the design approach, resulting in a very efficient product with integrated functionality. The new design leads to a structure weighing almost half of the original design.

And:

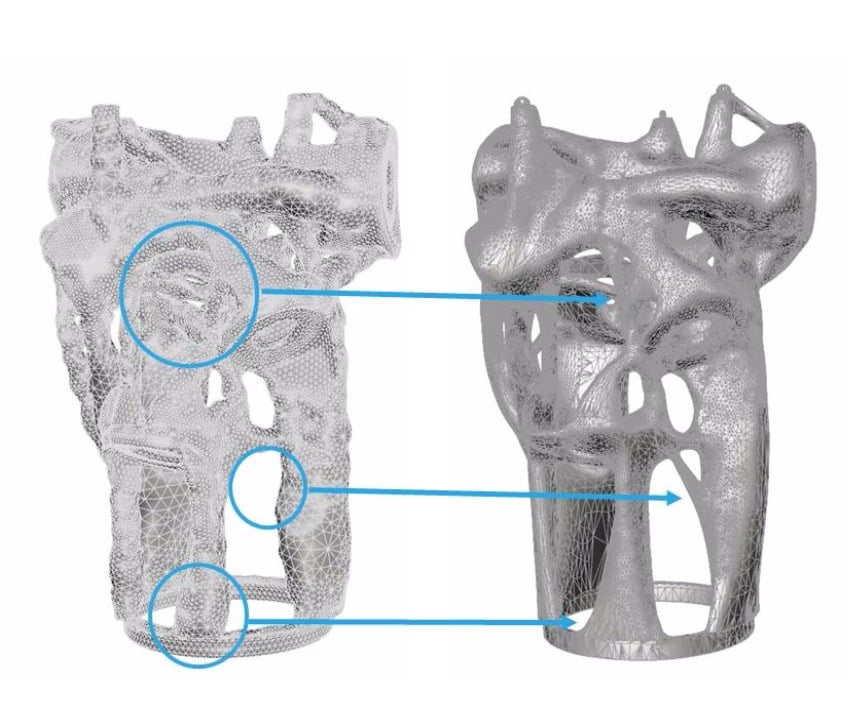

We looked at a whole range of available digital support tools to develop the design and automate the generative process for all nodes. The selected software showed good performance suitable for a specific task but lacked desired interaction and ease of operability for our design process. Automatic generative design of all the nodes in the structure is not yet possible in an efficient way. The whole process would highly benefit from appropriated software for an activity like this.

It’s a very complex process, as you can imagine, but this is a great step towards a future where such advanced building components are used routinely.

Via ResearchGate