During my recent conversation with MakerBot CEO Jonathan Jaglom, he told us their new SmartExtruder+ had been redesigned and tested extensively. I had no idea how much until now.

MakerBot published a story on exactly what they changed in the SmartExtruder+ to dramatically increase it’s performance and reliability. By looking at the nature of these changes, one can understand how they’re very serious about the level of improvement achieved.

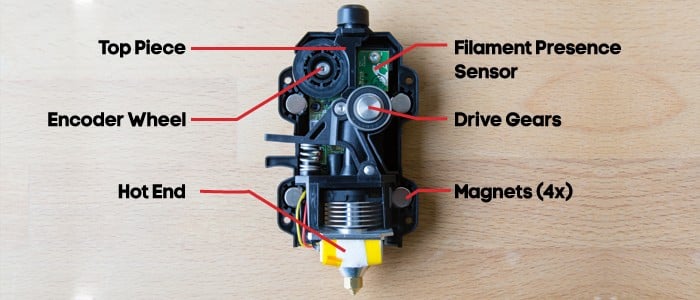

One major change was to “overmold” the “encoder wheel”. This is a circular item that spins slowly as the filament moves past. When filament isn’t moving, the encoder wheel stops and can trigger a filament problem. However, it seems that the original encoder wheel occasionally did not properly connect with the filament, thus triggering a false incident and affecting printing. If the encoder wheel was too tight to the filament to ensure contact, it’s conceivable it could have caused a jam itself!

The SmartExtruder+’s encoder wheel is overmolded with a soft layer that provides more consistent friction with passing filament, while not interfering with the flow. This is a very good design change.

They’ve also extended the PTFE tube through which the filament moves to cover the entire sequence between the extruder drive gear and the hot end itself. Molten plastic does not stick to the PTFE and thus stray plastic has nothing to adhere to and cause jams, as was the case in the original SmartExtruder.

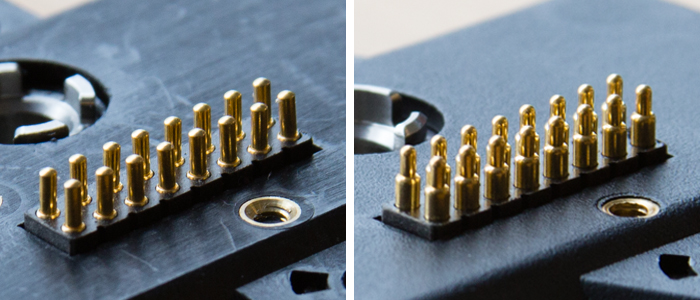

All SmartExtruders, new and old, use a magnetic connector to attach to the printer. While you might think this is a simple process: have a couple of magnets join the two together, it’s more complex, because electrical signals and power must be supplied to the SmartExtruder. These were accomplished through a set of gold-plated pogo pins. However, the extruder is a mechanical component that moves dramatically during print operations, causing a great deal of vibrations, particularly when printing complex shapes with many isolated sections. This could shake the pogo pins causing early wear or even momentary disconnection!

The new design has improved pogo pin shape, additional gold plating and stronger magnets. This should eliminate this failure scenario.

That’s the hardware changes that resulted in the SmartExtruder+, which we understand is seeing greatly increased operational reliability in the field. That’s not surprising, as MakerBot and parent Stratasys undertook some 160,000 hours of rigorous testing on the new extruder design.

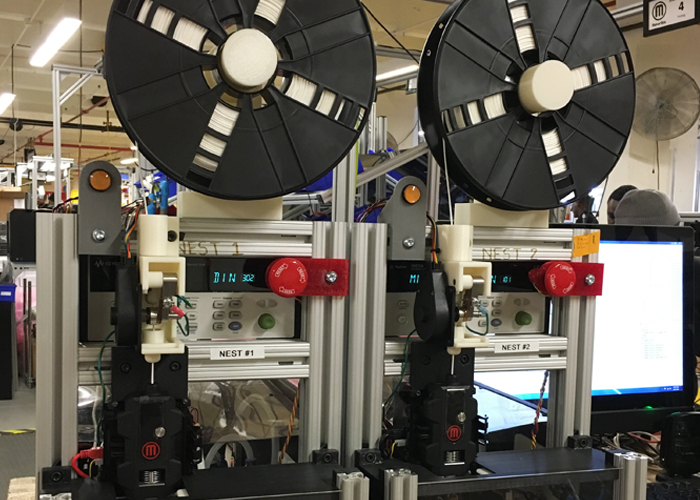

Finally, MakerBot has introduced a new quality test in their manufacturing facility to ensure all SmartExtruder+’s meet specifications. The test rig, designed with the assistance of Stratasys and shown here, runs the units through a standard test suite that covers major functions.

For a company that faced such difficulties with the original SmartExtruder, I cannot imagine what else they might have done to make the new SmartExtruder+ more reliable and to demonstrate to skeptical clients and prospects that this issue is now finally fixed.

Via MakerBot