Our team got a chance to take a close look at the ZMorph Multitool 3D printer.

There are plenty of desktop 3D printers on the market, but very few have the ability to do more than just 3D printing. The ZMorph SX 2.0 does, and in fact can do multiple functions.

They’re simply taking advantage of a commonality between many making machines: the cartesian X-Y-Z axis movements are used to move a toolhead around a work area. In the case of filament-based 3D printers, this mechanism moves the nozzle around to distribute plastic, but in other machines, such as a CNC mill, the milling head is moved around in a very similar manner.

The idea behind the multitool approach is that the motion system is shared between a series of toolheads that are easily exchanged. This transforms a basic 3D printer into a powerful making machine that can do more than one function.

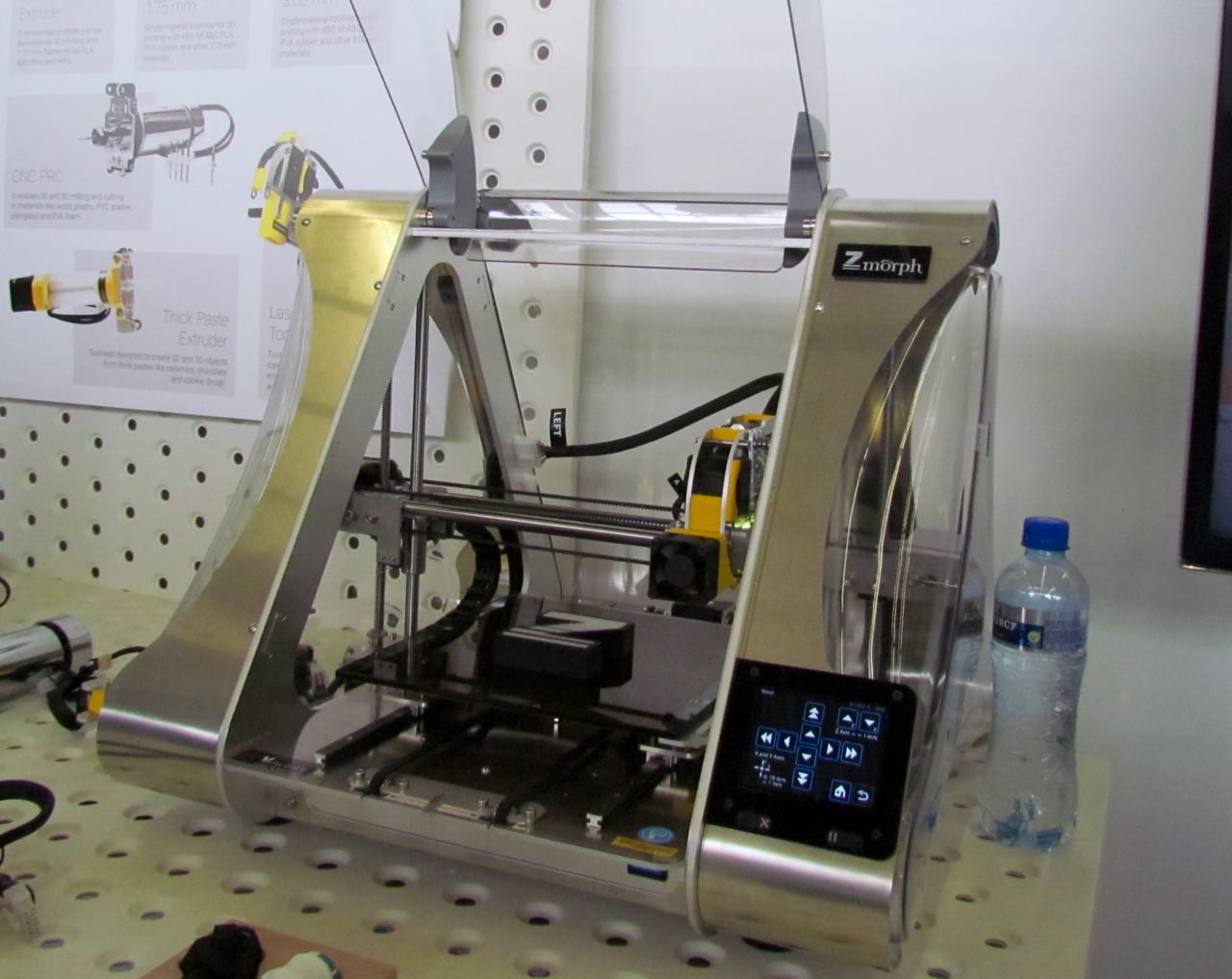

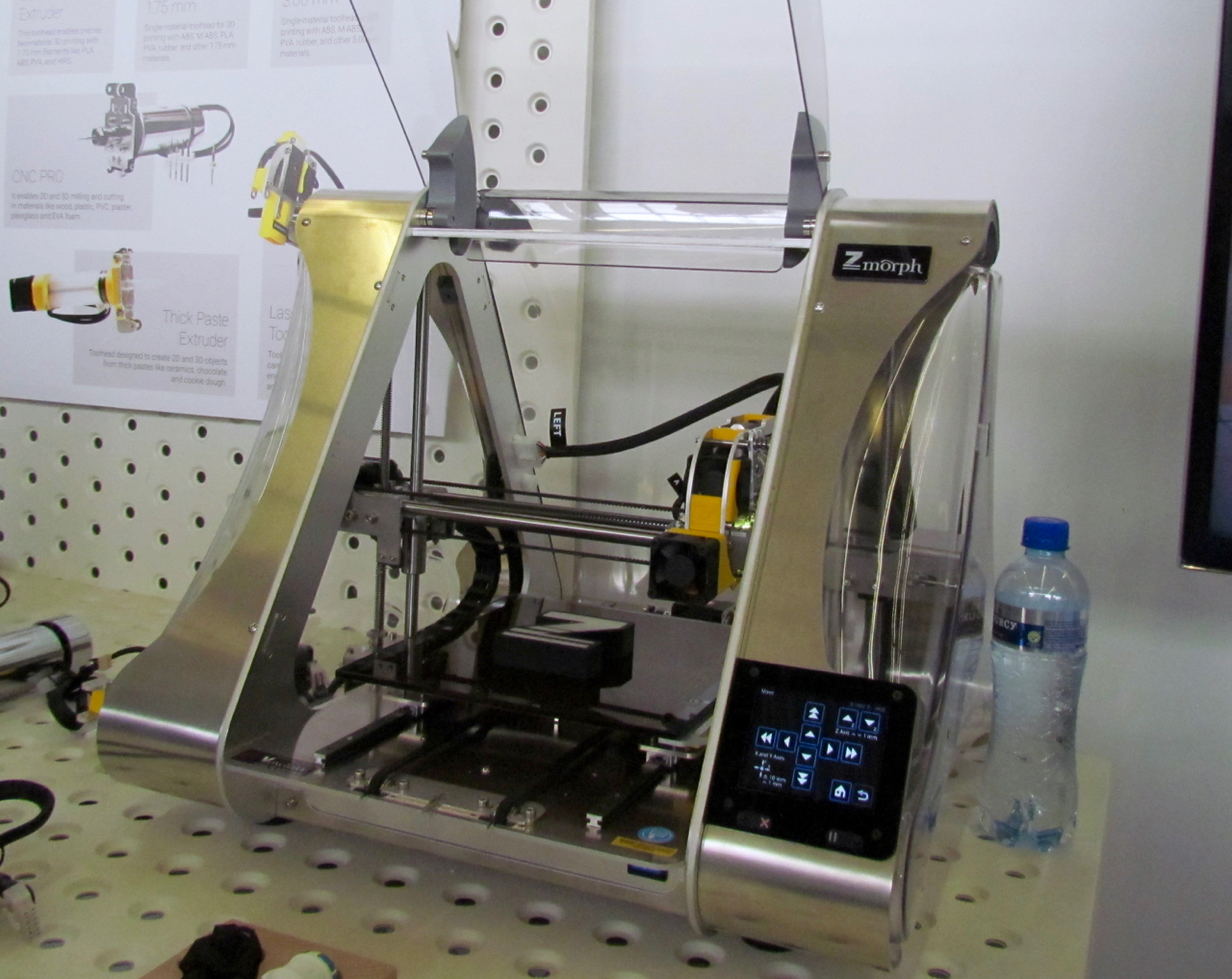

ZMorph’s latest release is the 2.0 SX, a powerful making machine that can perform many making functions with its interchangeable toolhead system.

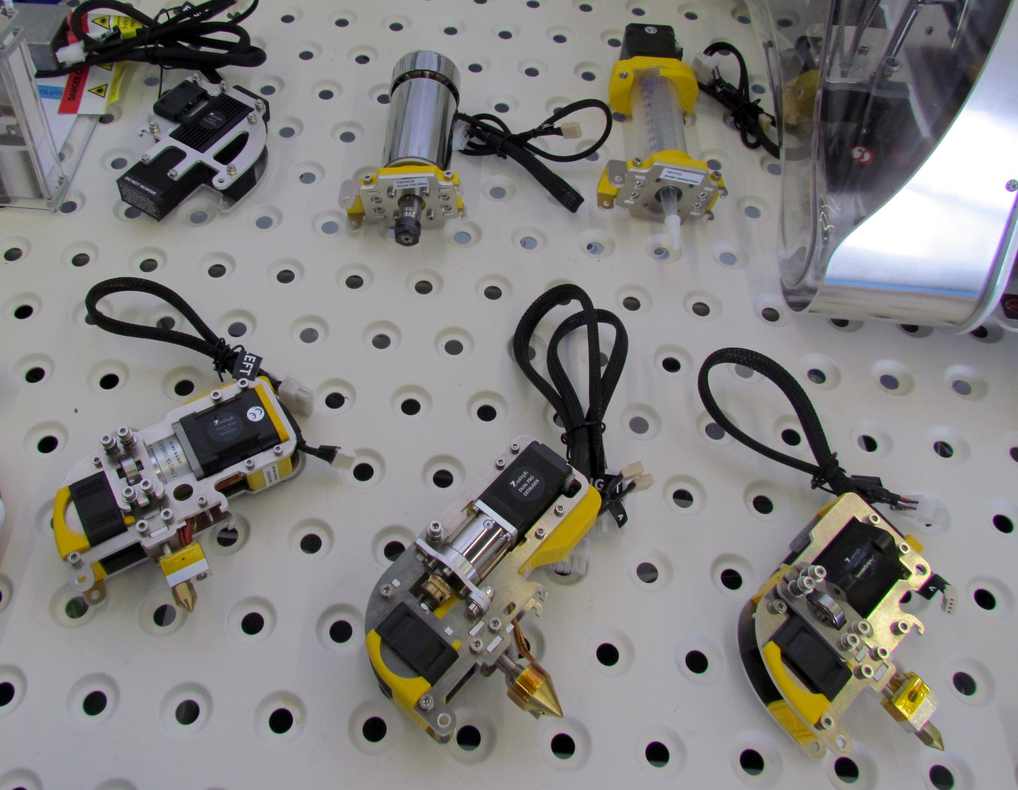

Here we see the array of toolheads currently offered, and remember, this is the CURRENT set. There’s nothing stopping ZMorph from adding additional functions in the future. Currently they offer:

- A 1.75mm diameter filament 3D print extruder (able to handle many different filament types)

- A 3.00mm diameter filament 3D print extruder (so you can use BOTH sizes of filament!)

- A dual-head extruder for 3D printing two materials in a single print operation

- A CNC milling head for carving soft materials like foam, light wood and wax

- A laser to cut thin materials or engrave on thicker materials

- A paste extruder for ceramics and food experimentation

That’s quite a few tools, but the usage enabled by combining these tools together is far more powerful than any one alone. For example, you could imagine making a custom circuit board with the milling head, 3D printing a case to hold it and extruding a silicone gasket for waterproofing all with the same machine.

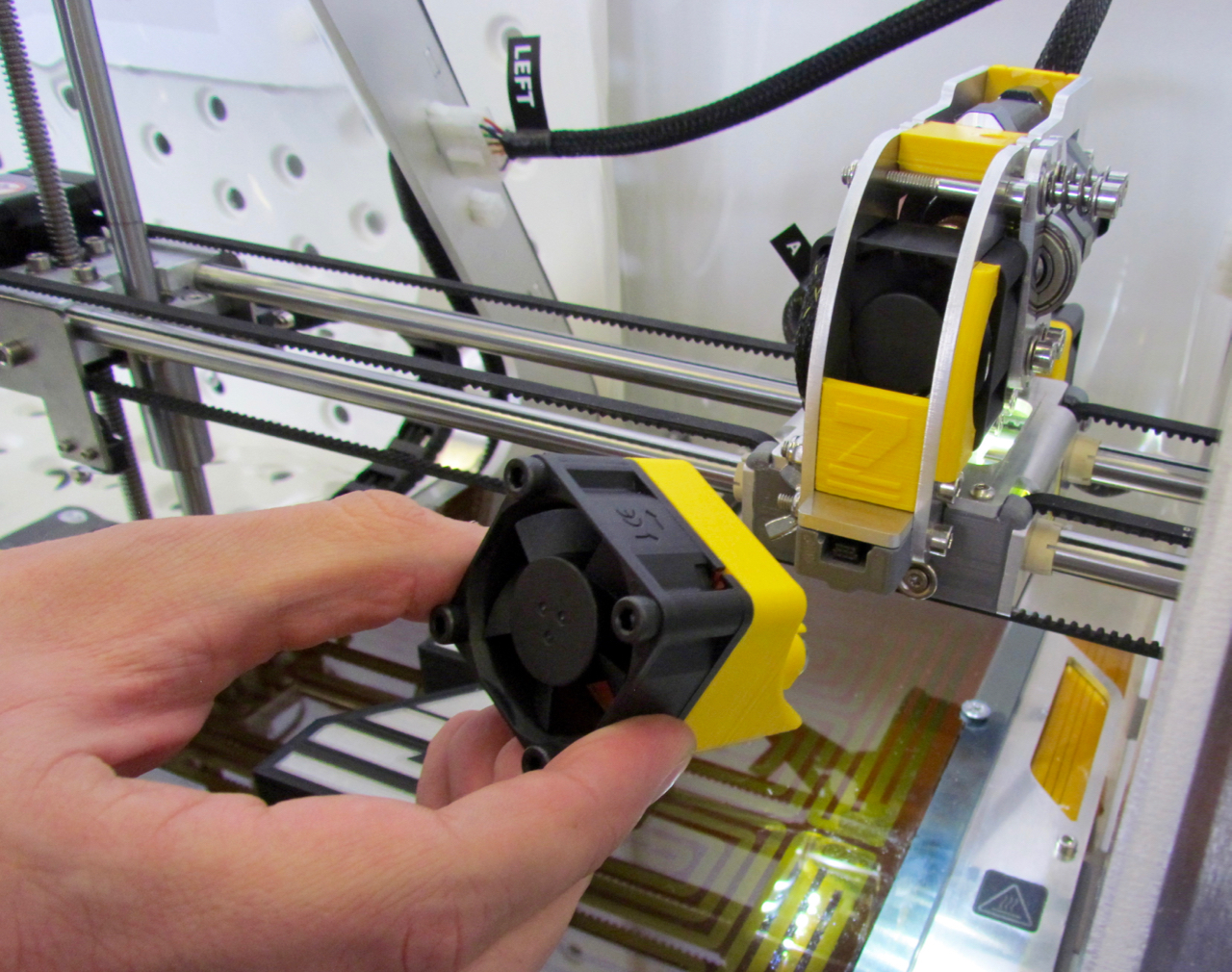

And it’s not just the toolheads that are modular. Here we see a fan system – not a toolhead – that simply snaps in as required. Many elements of this machine are designed to be modular.

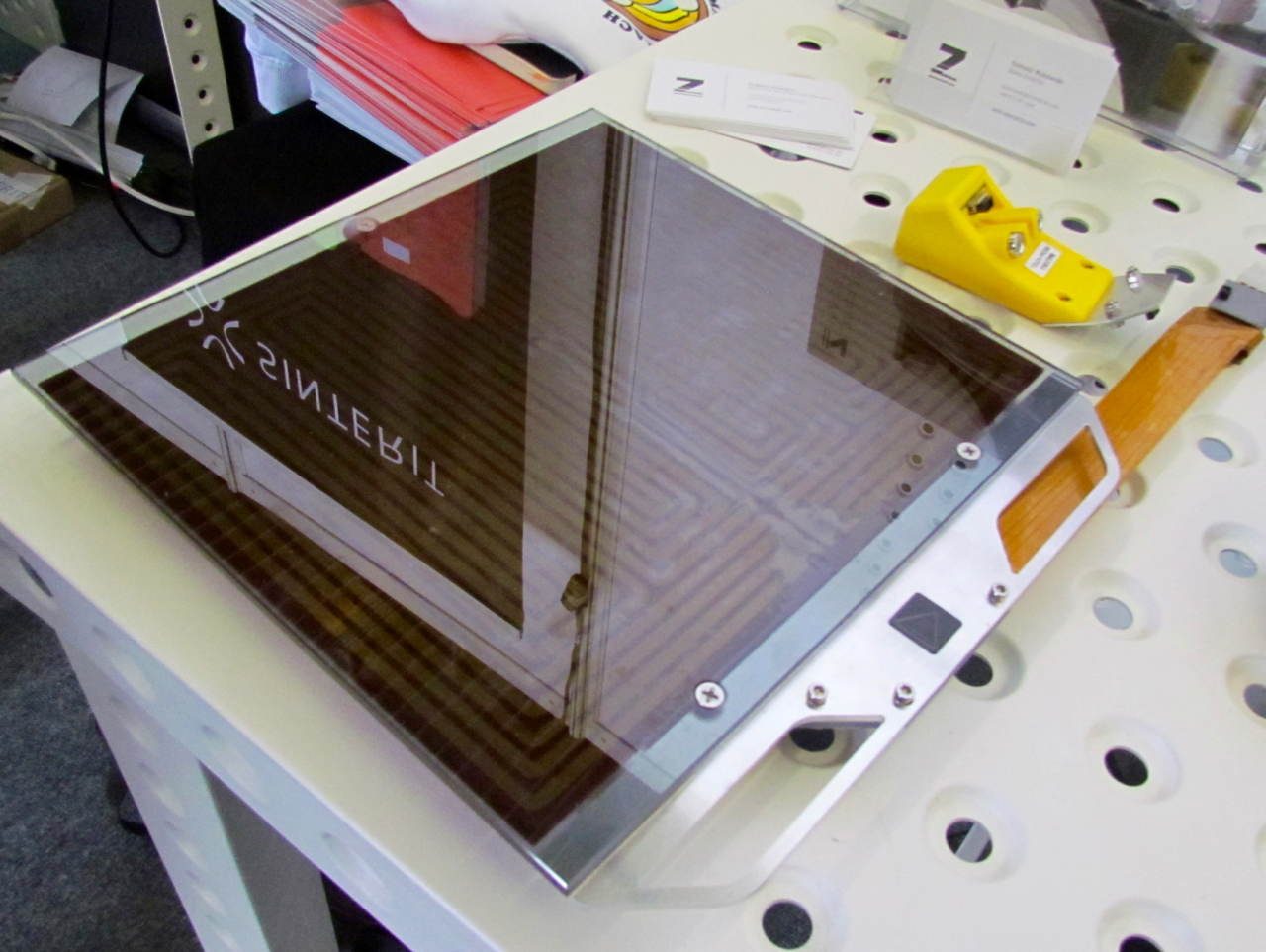

As you might imagine, you must also change the work surface for some of the tools. You likely don’t want the CNC milling head to dig deep into your delicate heated glass 3D print bed shown here!

Here’s an example of combined tooling made by ZMorph: a set of 3D printed items set into a custom CNC milled wooden box. The box has been laser engraved on the outside. Not shown: a flexible band 3D printed in stretchy material that can wrap the box and hold it all together. That’s the power this single machine can bring to a small workshop. In fact, the machine IS a small workshop on its own.

One question I raised was about cleanliness. While 3D printing is a relatively “clean” process with very little debris, that is definitely not the case with CNC milling, where bits fly everywhere. ZMorph is aware of this and explained that’s one of the reasons the 2.0 SX has covers on all sides.

For cleaning, they recommend vacuuming the interior after milling. This is especially important to avoid getting debris caught in the motion system’s belts in subsequent operations.

While the machine is recommended to be used only in very well-ventilated areas, they are apparently developing a HEPA filter to drastically reduce emissions.

ZMorph tells us their business is growing through their increasing large network of resellers and distributors worldwide.

You can order a 2.0 SX yourself, but you’ll have to choose between two options: a lower cost USD$2,690 model that includes the 3D print and CNC milling tools, or a higher cost model that includes ALL the toolheads for USD$3,890. I think I’d prefer the latter!

Via ZMorph