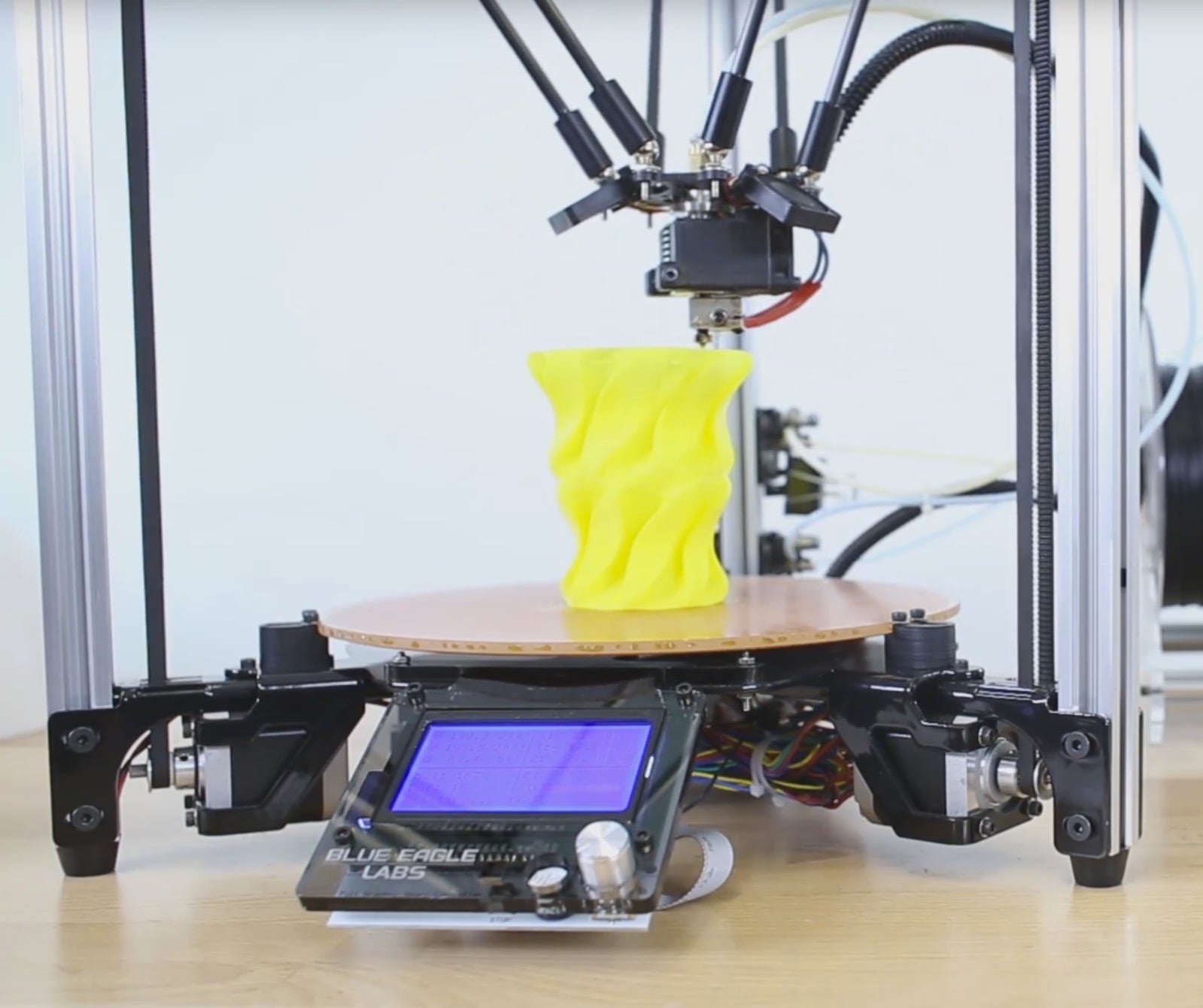

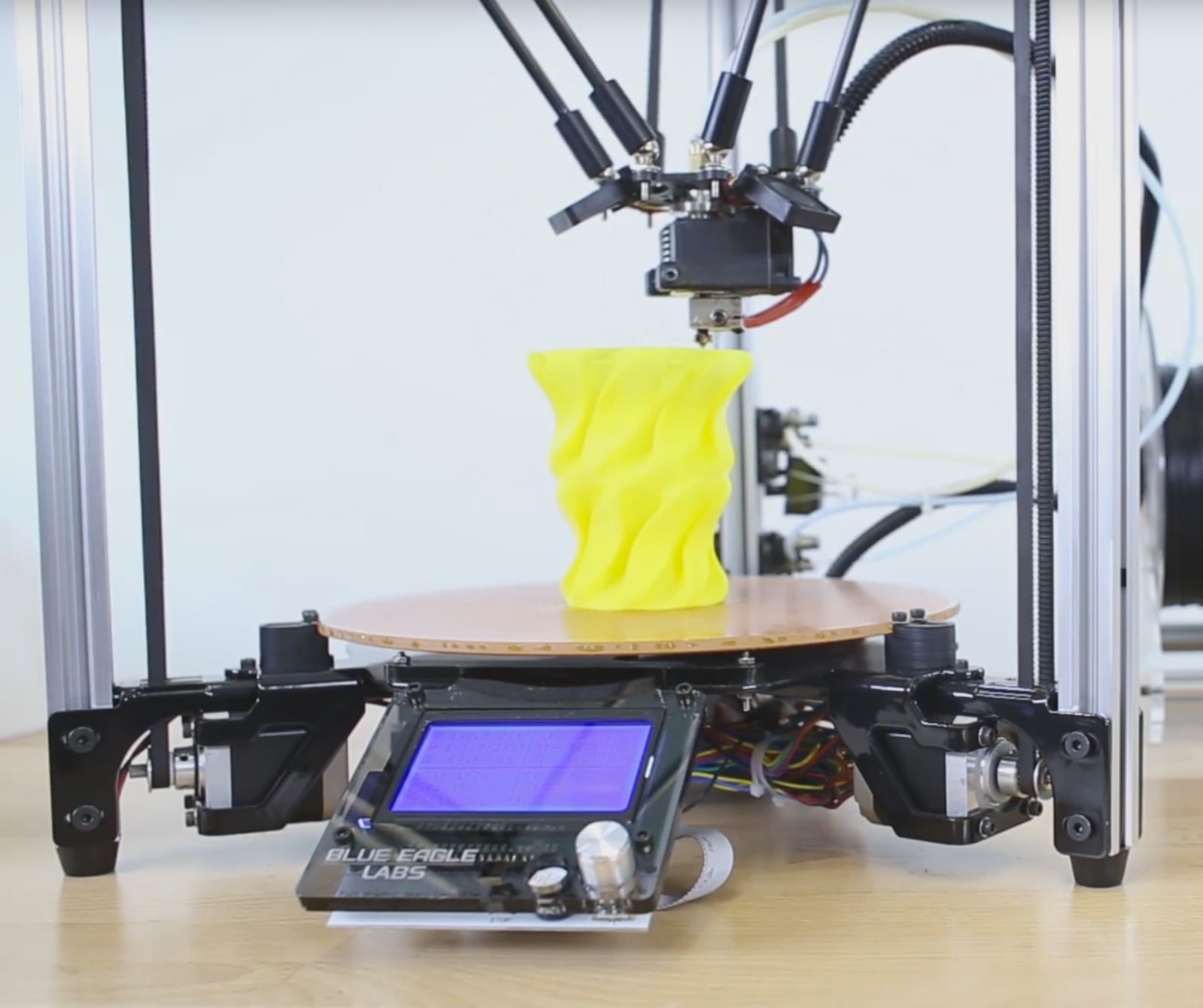

Now on Kickstarter, the Metal Delta 3D printer from Blue Eagle Labs offers some very interesting features at a very low price.

Blue Eagle Labs previously sold the Kossel Clear delta 3D printer on Kickstarter in 2013, which was wildly successful, reaching almost 27X their funding target. It took them a year to make and deliver the machines, but they did so.

Now they’re launching a vastly improved machine, the Metal Delta. While the new machine is also a delta-style device, like its predecessor, the Metal Delta includes a number of interesting features.

First, the machine include a number of robust parts, some made from “3mm hot rolled steel”, like the all-metal frame. There’s also “Ultra-Precision Magnetic Ball Joints” to provide easy movement as well as a rapid method of swapping out the toolhead. They say the arms of the Metal Delta are essential “zero backlash”, with a maximum of 0.05mm variations within movements.

All these changes mean the prints should be of higher quality and the machine should be reliable.

The build volume is reasonably large, 250mm diameter by 280mm tall, and the machine includes an auto-calibration feature.

The company has also decided to use faster 32-bit controllers and 0.9 degree stepper motors that could translate into higher print resolutions.

But there’s more.

This machine includes a dual extruder, and it’s not like the ones you normally see. It’s actually a specially designed hot end that can accept two input filaments and mix them on the fly. I’m not sure they have the software to properly drive this feature, but it’s certainly a very advanced feature to find on a low-priced unit like the Metal Delta.

For extra cost you can add a laser engraver! This toolhead simply snaps in and out courtesy of the magnetic ball joint attachments. This transforms your 3D printer instantly into a laser engraver, with its 2W laser. This should be sufficiently powerful to engrave wood and cut paper, but not not cut wood. Very useful, nevertheless.

Also for a small fee you can add an advanced print surface from GeckoTek that is magnetically attached and provides a permanent adhesion surface for highly reliable 3D printing.

Finally, the machine is bundled with Autodesk Fusion 360, a popular 3D design tool, or at least one year subscription to the service.

I should mention that the Metal Delta is in fact a kit that you must assemble yourself. Now before you dismiss this option, you should know that Blue Eagle Labs has spent considerable time engineering this machine to be very simple to assemble. They’ve designed the parts in such a way as to simplify installation of components significantly. In fact, they say the entire machine can be built in only five hours.

You might be wondering how much this interesting machine is going to impact your budget, and it’s actually quite low. Keep in mind the pricing is at Kickstarter levels, so perhaps it may rise in the future, but for now, you can get the basic PLA-only kit for only USD$499. An ABS-capable version (with heated bed) is now USD$599, still a great price. A full version with all upgrades (less the laser engraver) is USD$800, and it’s USD$900 with the laser.

All good prices for what seems to be a very reasonable 3D printer.

Via Blue Eagle Labs and Kickstarter