At the beginning of this week I headed to Chicago for IMTS.

I’ll be honest, travelling alone to a massive show in a huge US city when you spend most of your days in a small village is fairly intimidating. It is also exciting, and they don’t come much bigger than IMTS, held bi-annually by the AMT (Association for Manufacturing Technology).

In the interests of full disclosure – I was present as a guest of 3D Systems, who held a press event on Monday 12th September to unveil a new visionary strategy along with a couple of new products, sort of, but more on that later. Due to the nature of my travel arrangements, I had a few free hours on Tuesday to have a quick peek at other additive things – as you do! There was no chance of exploring the other manufacturing tech on show in a few hours, the exhibition is vast.

IMTS is spread over all four buildings (North, East, South and West) of McCormick Place on the shore of Lake Michigan with more than a million square feet of exhibition space (1,370,256 to be precise) accommodating 2407 exhibitors. According to the organisers, this years IMTS was the largest ever in terms of exhibitors, with registered visitor numbers being reported at well over 100k.

One new addition to IMTS this year was the Additive Manufacturing Pavilion, which was housed in the North Building. I definitely had the sense that the AM Pavilion was “tagged on” in terms of size and positioning. It was a tiny section (less that 1%) in the context of the entirety of the show as quantified above. However, to be clear, using the ‘tagged on’ line above is only applied to the size of the AM exhibits — without doubt the addition of dedicated AM space was not an after-thought, its prominence as a valid and growing manufacturing technology was clear throughout all of the visuals and daily marketing press, it was also supported by a two-day conference (hosted in the West Building, which was not particularly helpful). However, the size of the AM pavilion at IMTS served as an appropriate analogy and timely reminder for where exactly AM fits in the realms of manufacturing technology in 2016.

3D System’s presence at IMTS was perhaps the most pervasive on the AM front. Obviously that can be viewed as a subjective comment based on the above disclosure, but actually I’m saying it based on the fact that the company had a presence in three of the four buildings. Naturally there was a stand within the AM Pavilion, front and centre as it goes, supported by a large booth in the East building within the CAD/CAM Pavilion and featuring the company’s array of ecosystem software and software partnerships. 3D Systems was also present in the South Building, courtesy of its partnership with machine tools company Methods 3D. To provide some perspective, Methods’ stand was probably comparable in size to the entire AM Pavilion, and it featured an iteration of 3D Systems’ new modular Figure 4 production system.

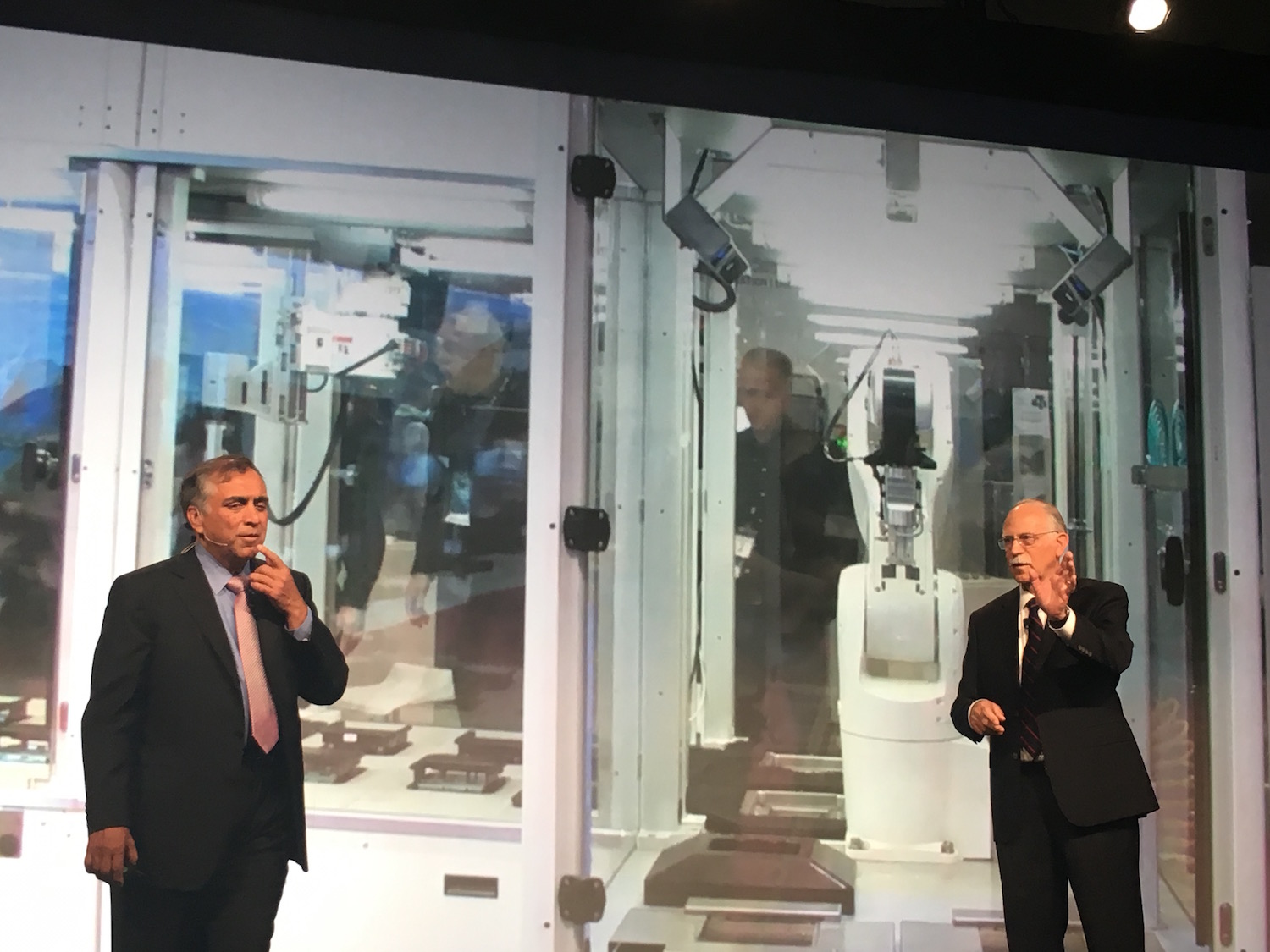

Originally unveiled at CES in January, and later at AMUG, this is an automated manufacturing line configuration with 3D printing embedded as the production process. The configuration includes the automated production, post-processing and in-line monitoring of high volumes of plastic parts/products enabled by the integration of 3D printing, robots, scanning and software. Anticipating commercialisation of this system in 2017, there was no visibility on pricing, but even when the pricing comes, it will not be standard, due to the modular nature of it. This system is a production solution and as such, customer requirements will be different, therefore each solution will be designed to meet individual requirements.

Interestingly, some of the IP for the Figure 4 was originally filed in 1984 by 3D Systems founder Chuck Hull, highlighting how the vision for automated additive manufacturing was there 32 years ago. In 2016, however, the transition from prototyping to production is central to 3D Systems strategy and vision, as unveiled by CEO Vyomesh Joshi (VJ) during a two-hour keynote address. With a notable outward looking focus, open approach and complete prioritisation of the customer in all operations, 3D Systems’ demonstrated a whole new approach to leading the 3D printing industry.

The AM Pavilion also housed the booths of the North American divisions of voxeljet, EOS, Envisiontec, Concept Laser and SLM Solutions — all countries with their headquarters in Germany. The US companies were, naturally, there in force too. 3D Systems, as mentioned, together with Stratasys, Optomec, ExOne, Sciaky, HP Inc and Carbon, the latter of which also had a stand in the West Building.

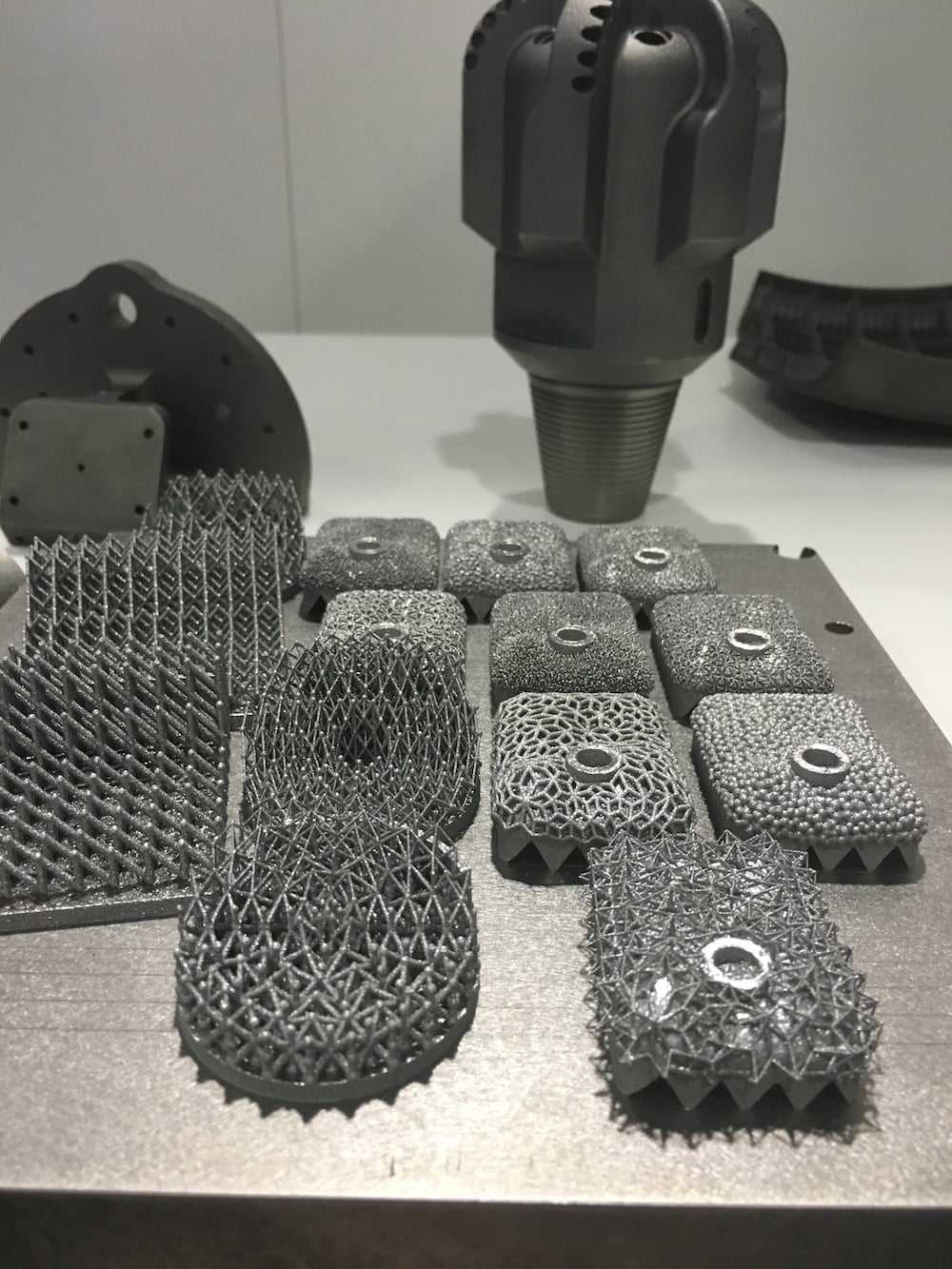

UK based AM company Renishaw was also present at IMTS, but only in the East Building in the Quality Assurance space. Renishaw had a vast stand, competing well with Hexagon, Zeiss et al on the metrology front but the company was also exhibiting the RenAM 500M system, which was gaining a great deal of attention. I caught up with Stuart Jackson, two weeks into his new Business Development role at Renishaw after leaving EOS at the beginning of the summer after 14 years. It was a big change, but one that I believe will be mutually beneficial. We chatted at length about the AM industry, mostly the metals part of it, and the shift towards production applications — a notable theme this year and crystallised by IMTS 2016.

The proposed GE acquisition of SLM Solutions and Arcam was also a recurring theme of convervations at IMTS. Stuart was upbeat about it, as was Stefan Ritt, long-time sales and marketing director at SLM. He did reinforce how early in the process things are though, it is certainly not a done deal for GE yet. For the record he thinks it probably will be but highlighted how many news channels did not report on the actual information that GE released last week, but rather on assumptions based on that information.

I also discussed this subject with Andre Wegner from Authentise, which released new software earlier in the week. He had mixed feelings about the acquisition bid, particularly with regard to users of the EBM process and whether it would remain a commercial technology, or become an internal tool for GE. It’s always insightful talking with Andre, based between Africa and Silicon Valley and his perspective is always valuable beyond measure. One of the really insightful topics that we moved on to was to do with the “metals vs plastics” thing that is happening in the 3D printing space. When talking about production, we both agreed, most people make the immediate assumption that it is only about metal additive manufacturing. For some time this has niggled me (on and off, you understand). That said, the 3D Systems vision is fighting this myth, stressing that plastic production with 3D printing will be huge.

One company that has long been pushing this message is the other leader in the field — Stratasys. With its Fortus machines and Ultem materials, Stratasys has been able to demonstrate proof of plastic 3D printing production for years. Moreover, at IMTS I got to see the two new industrial demonstrator concepts up close for the first time. Both the Robotic Composite 3D Demonstrator and the Infinite Build 3D Demonstrator take Stratasys’ intent in this regard to the next level. I knew they were going to be big, but seeing them in real life, really brought home Stratasys’ commitment to manufacturing. Talking with Joe Hiemenez, the key for Stratasys has always been applications, with which I concur, and the raft of user stories from Stratasys is increasing week on week.

Another company that is focusing on 3D printing plastic production is Carbon. It was great to catch up with Dana McCallum, who gave me a heads up on their latest investment and growth news, which is not insignificant. Further investment of more than $80 million from customers, speaks volumes about how customers — and potential customers — are reacting to the capabilities of the CLIP process and Carbons materials portfolio.

And of course, HP Inc has a vested interest in 3D printing plastic production capabilities with its new MJF process and materials. Away from the tech for a minute, and there was a moment that could have been (maybe once upon a time, would have been) awkward. Based on history and not a little irony, 3D Systems’ CEO, VJ’s tenure at HP has been well-documented — he was there 32 years — as has HP’s entrance into the 3D printing industry. HP’s new worldwide PR person for HP Inc’s 3D business is one Michele Guthrie, who made contact with me, via social media, while I was at IMTS. When I caught up with her in person, I learned that she’s been with the company quite a while, but only transitioned over to the 3D portfolio a couple of months ago. Turns out she was hired originally at HP “back in the day” to manage VJ’s executive communications. Like I said – could’ve been really awkward, but the genuine warmth in the way that they each talked about the other was lovely, it really struck me actually!

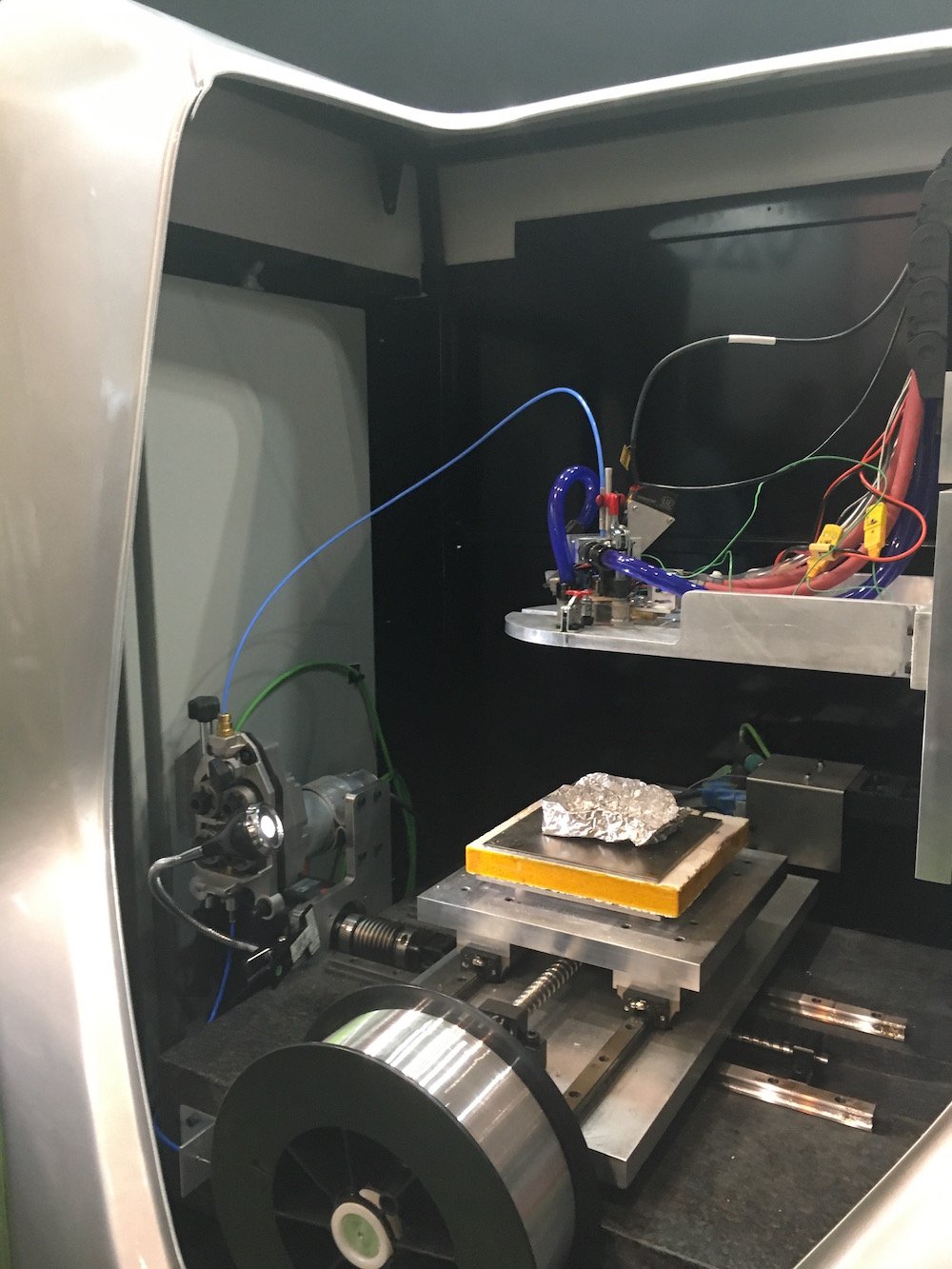

Back to additive metals though and there were two stand out novelties debuted at IMTS. The first came from established AM company Optomec, with its new LENS tool series for low-cost, high-value hybrid manufacturing that integrates AM with traditional CNC processes. I caught up with Ken Vartanian of Optomec who was also presenting at the show. The other came from Vader Systems which was making its worldwide debut of the MagnetoJet technology. I talked with Jenae Pitts, Vader’s Director of Business Development, who explained more about the liquid metal additive process, which uses inexpensive aluminium wire (various alloys) that is melted in a specially developed extrusion head to produce “fully dense” parts that can be subsequently machined. The process itself, I learned, has been developed after considerable research into Magneto Hydro Dynamics (hence the name) that allows for the manipulation of liquid metal by way of magnetism. The MK1 Experimental machine was opened up and on show, with a range of parts. As the name suggests, it is not commercially available yet, but that is expected in 2017, Janae told me. Definitely one to keep an eye on, I think.

My time at IMTS was short, and with hindsight, I really wish I had built in an extra day or two. But lesson learned for 2018, when I envisage the AM pavilion will be considerably bigger!