Multi-color – or indeed multi-material – 3D printing just got a little bit easier with a new deal between Type A Machines and Mosaic Manufacturing.

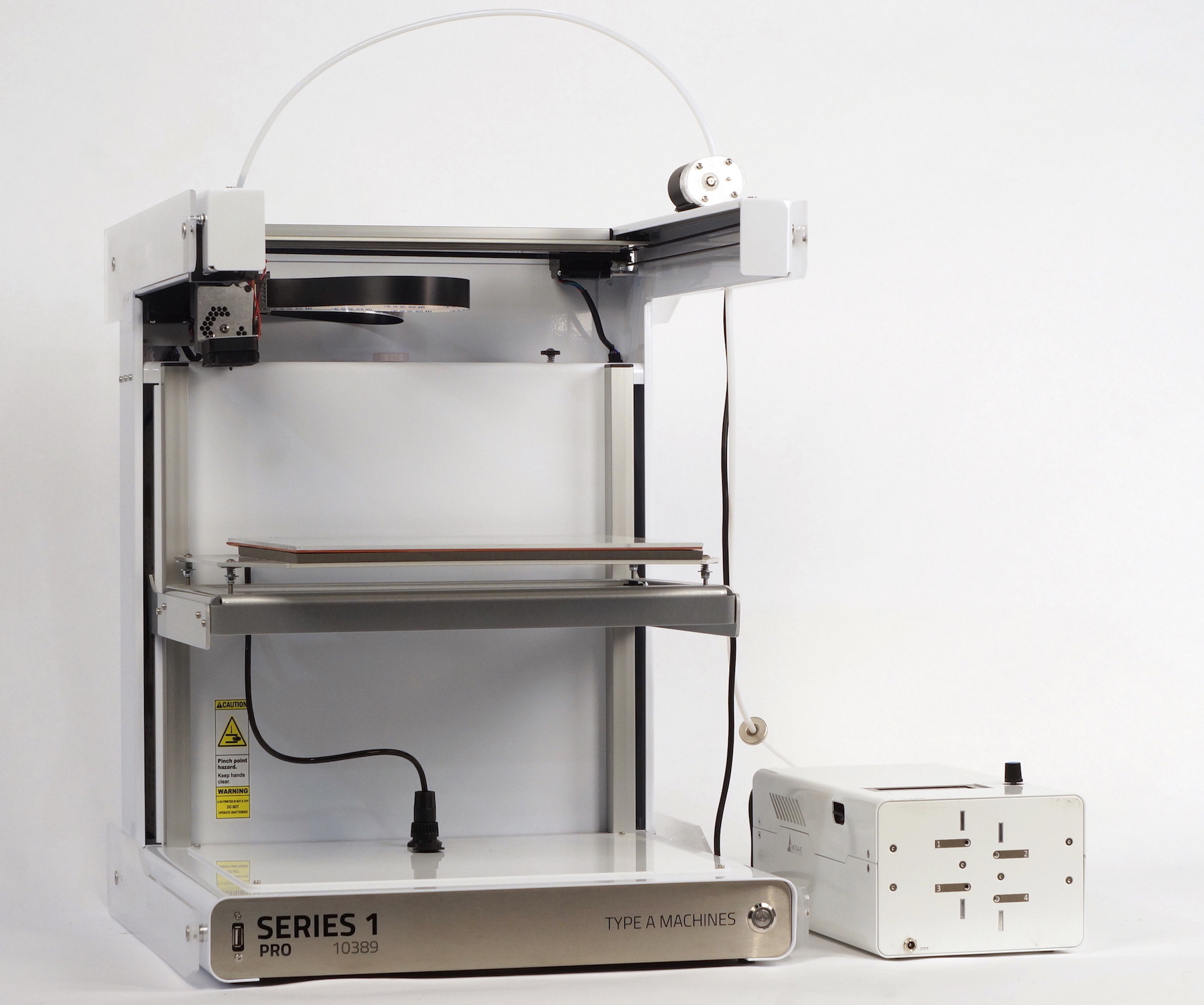

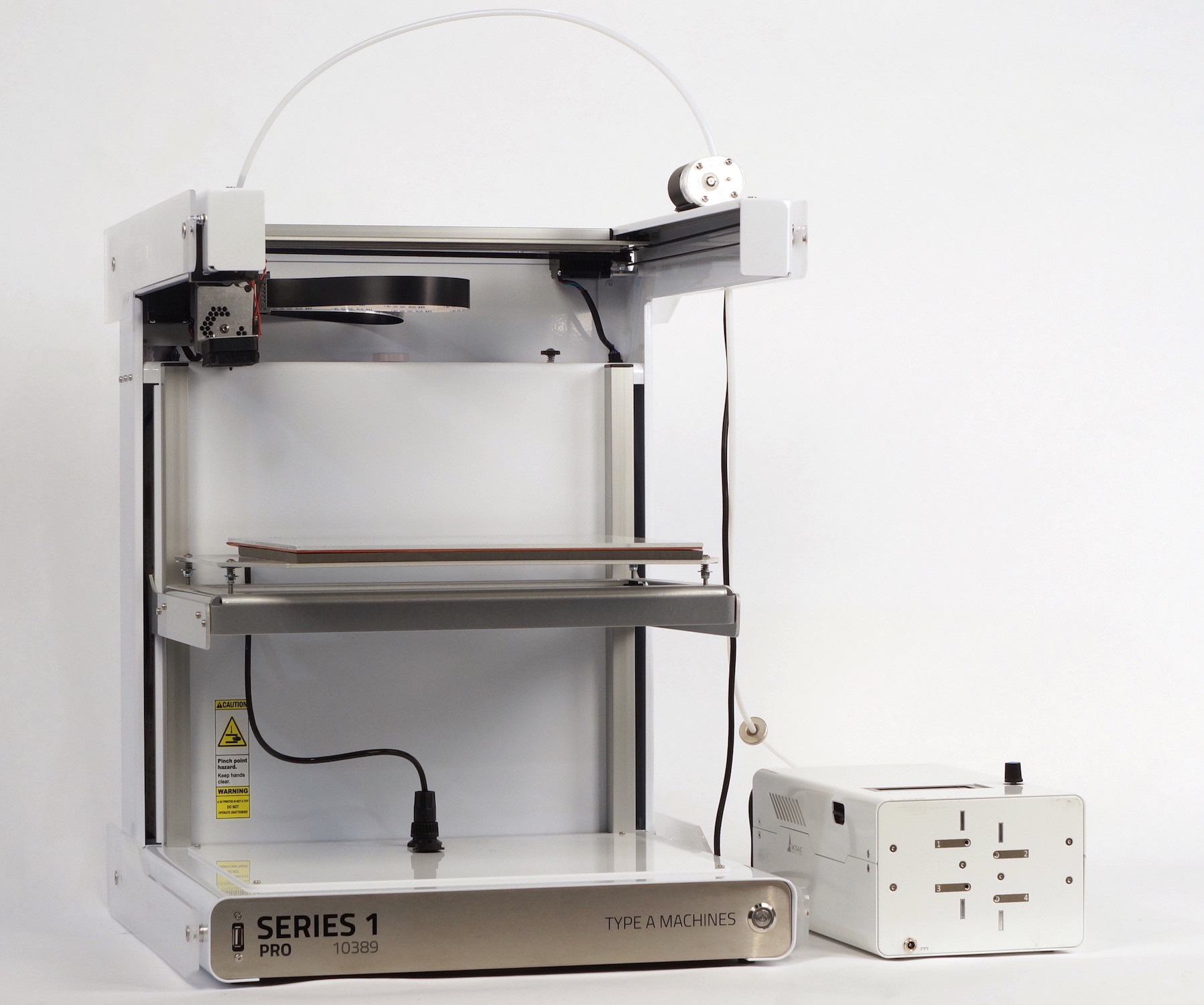

Type A Machines is a notable manufacturer of highly robust professional 3D printers capable of printing in a wide range of materials. Their equipment includes features designed for engineering use, beyond common hobby-style desktop models.

Mosaic Manufacturing is a Canadian company we first saw two years ago. They don’t produce a 3D printer, but instead market a rather unusual accessory: a device that dynamically creates a custom filament to effect material changes in a single extruder 3D printer.

Wait, how does that work? They examine the GCODE of a multi-material print and determine the precise lengths of each material required. Then these precisely measured segments are cut from input spools and fused together to produce a filament that will magically swap materials during printing – without stopping printing, reheating “other” hot ends and definitely not snagging the print or dripping on it. Watch their video to see how it works:

It seems incredible that you could actually do this, but apparently Mosaic Manufacturing has figured it out, and the results are very good. Color swaps are minimized by the abrupt change in material as the filament passes through the hot end. I’m not certain, but I suspect they may force a nozzle wipe at these changes to ensure the color change is sharp and well defined.

What is the deal being announced? It’s pretty straightforward: Type A Machines will market the Mosaic Manufacturing system, the Palette, in the USA on their behalf.

The deal should provide Mosaic Manufacturing with a big marketing boost in the USA through Type A Machines’ distribution network.

But there’s something else that’s really interesting about this deal: The Type A Machines’ fleet of machines is designed for professional use, not hobby use. While you may have thought the Palette could have been used for fun multi-color prints (and it can indeed be used in that way), it gets a lot more interesting when you use different materials instead of different colors.

Imagine if you removed the Red, Green, Blue and White filament spools from the Palette and instead loaded it up with, say: Extra-strength, Flexible, Clear and Conductive filaments. With that combination you might literally be able to print a functioning electronics case with press-able buttons, a window and even electrical connections. Type A Machines’ equipment just got a lot better.

That’s a smart way to make a 3D printer a great deal more powerful. And it’s only USD$999.

Via Type A Machines and Mosaic Manufacturing