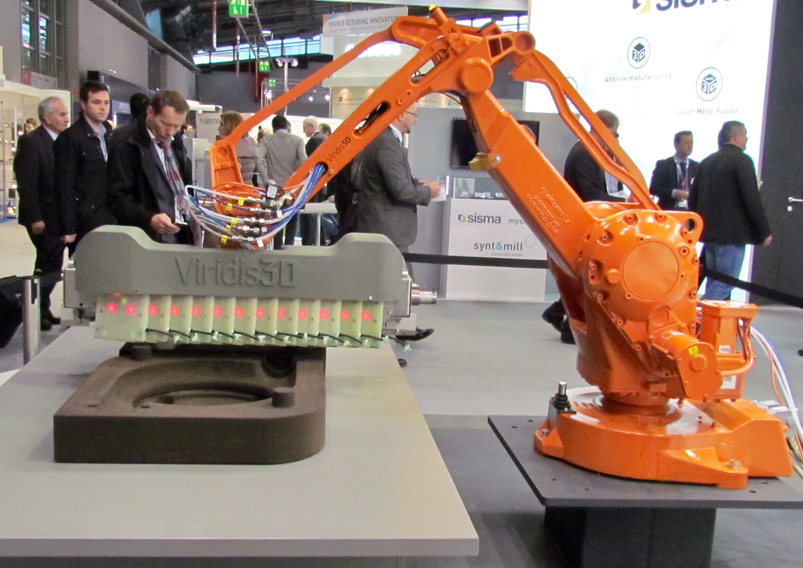

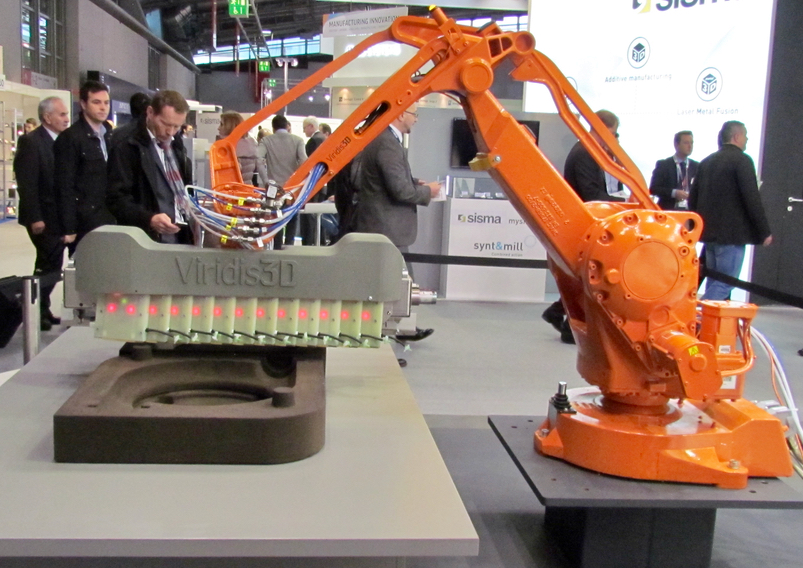

EnvisionTEC’s subsidiary Viridis3D has been developing a unique system for 3D printing sand molds for use in foundries.

Sand 3D prints are not new to the industry. They are commonly prepared using several different processes, most typically binder jetting: a flat sand bed is selectively bound using jets of binder. The resulting sand object can then be used as a mould for casting larger metal objects.

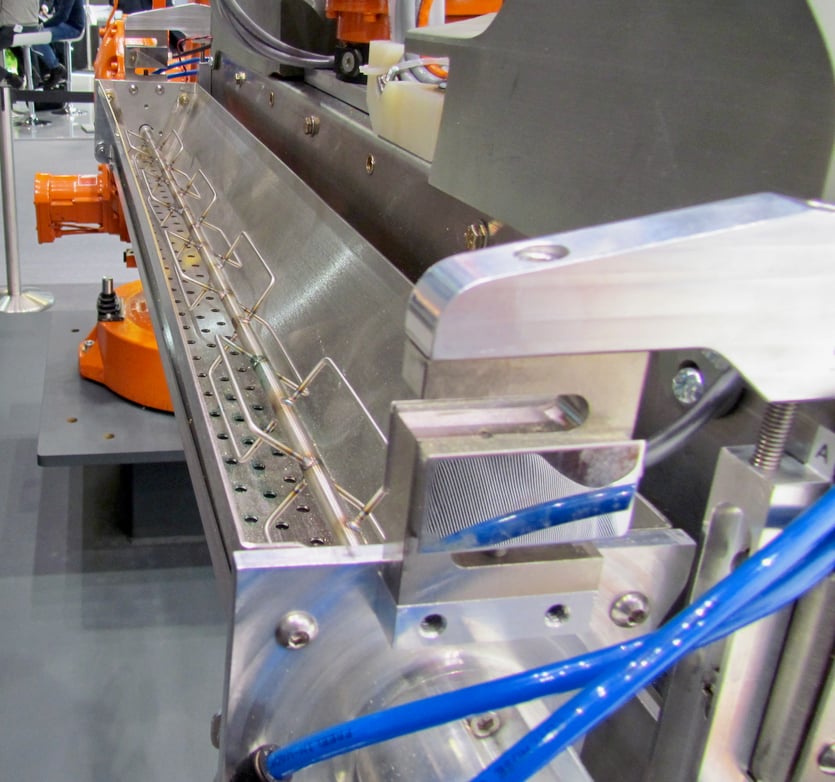

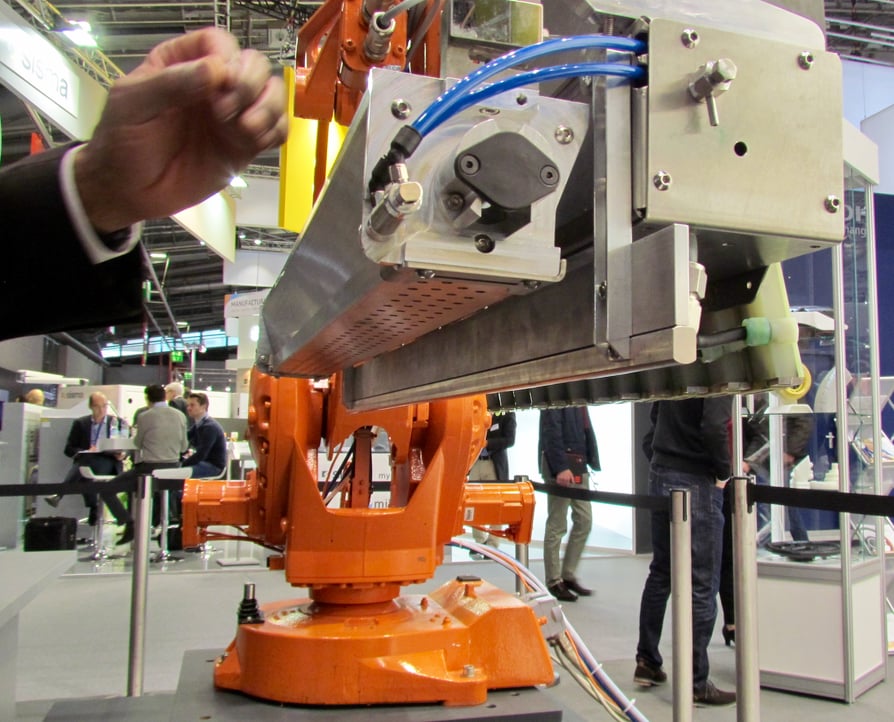

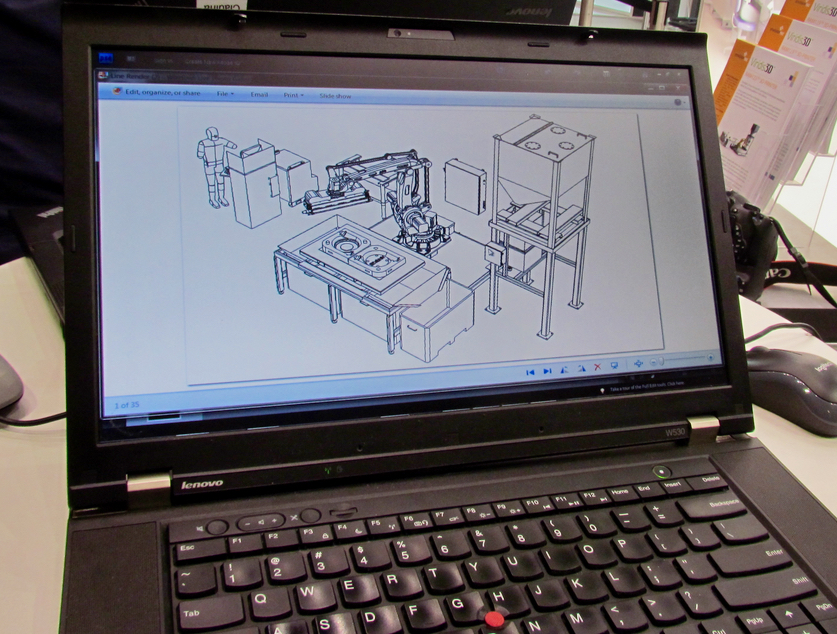

Viridis3D’s new solution also produces sand molds, but in a slightly different way. The RAM360 concept involves use of a standard industrial robotic arm holding a very special extrusion device.

The extruder sprays sand AND binder over a flat surface to gradually create a solid sand object.

Wait, you ask – how is the sand contained? Where are the walls?

There aren’t any! The system is designed to operate on any nearby convenient flat surface. Yes, there will be some stray loose sand, but it’s not a big deal. Simply brush off the excess material and you have a completed print.

Support for overhangs is provided by unprinted sand underneath the model.

The robot arm is also handy in that it can carry the 28” (711mm) wide extruder to a refill station when it is low on material. The entire system is comprised of several separate units, including the hopper robot, a build table, and a service station.

Standard casting materials are used, which presents a considerable cost savings advantage over some other systems. The standard price for such materials is only USD$0.07 per cubic inch.

But the secret to the RAM360 is really its pricing. While it seems a bit expensive at USD$350,000 per system, that’s actually substantially lower than that of its “closed box” competitors that might be priced at a million or more USD$.

It also turns out that a majority of foundries are small “mom and pop” operations with revenues around USD$20M. These companies would only make a profit of around USD$1M per year, making typical sand 3D printing systems utterly unaffordable.

But then, they have the RAM360 to consider now – and it should fall within the budget of a huge number of foundries.

Via Viridis3D