At this stage of development, you might wonder what possible improvements could be done on a standard filament-based 3D printer. Tt turns out Xioneer has figured out several.

The small Austrian company has released the X1, a “B2B” machine for industrial use. It includes a rather large build volume of 300 x 300 x 310mm, and can print layers as small as 0.1mm in height.

The machine is fully enclosed, able to capture excess heat from the 500W heated print surface. There’s a detachable flexible print sheet that includes a permanent coating for excellent adhesion. That 500W heated surface, by the way, is powerful enough to heat up to temperature in less than five minutes.

In spite of the heated bed and enclosed chamber, the X1 prints only PLA and PLA-composite materials. These are supplied in proprietary cartridges that are chipped for security and usage tracking. Thus, this is a closed materials machine.

However, the reason for this, according to Xioneer, is to enable extremely precise tuning. By controlling the input material and the machine, the company is able to provide printing profiles that work extremely well.

But there are two innovations in particular that are quite notable.

First is their automatic bed calibration. While many desktop 3D printers these days do include some form of automated or semi-automated leveling process, Xioneer’s is way beyond anything I’ve previously seen.

Their calibration approach involves using a sensor to measure the heights of no less than 50 points on the print surface with 20 micron accuracy. From this they can generate a kind of topological map of the surface, which is then used to adjust print operations for perfect printing.

Ah, but you say there’s more to calibration than simply the print surface. You’re right. The X1 is a dual extruder system with two nozzles. The dual nozzle configuration requires much more calibration because the two nozzles must be perfectly aligned.

That kind of happens on the X1, but in a slightly different way.

Each nozzle has its height individually calibrated, which is quite important because the nozzles move independently from each other. The X1 is one of the few systems with this type of extrusion motion.

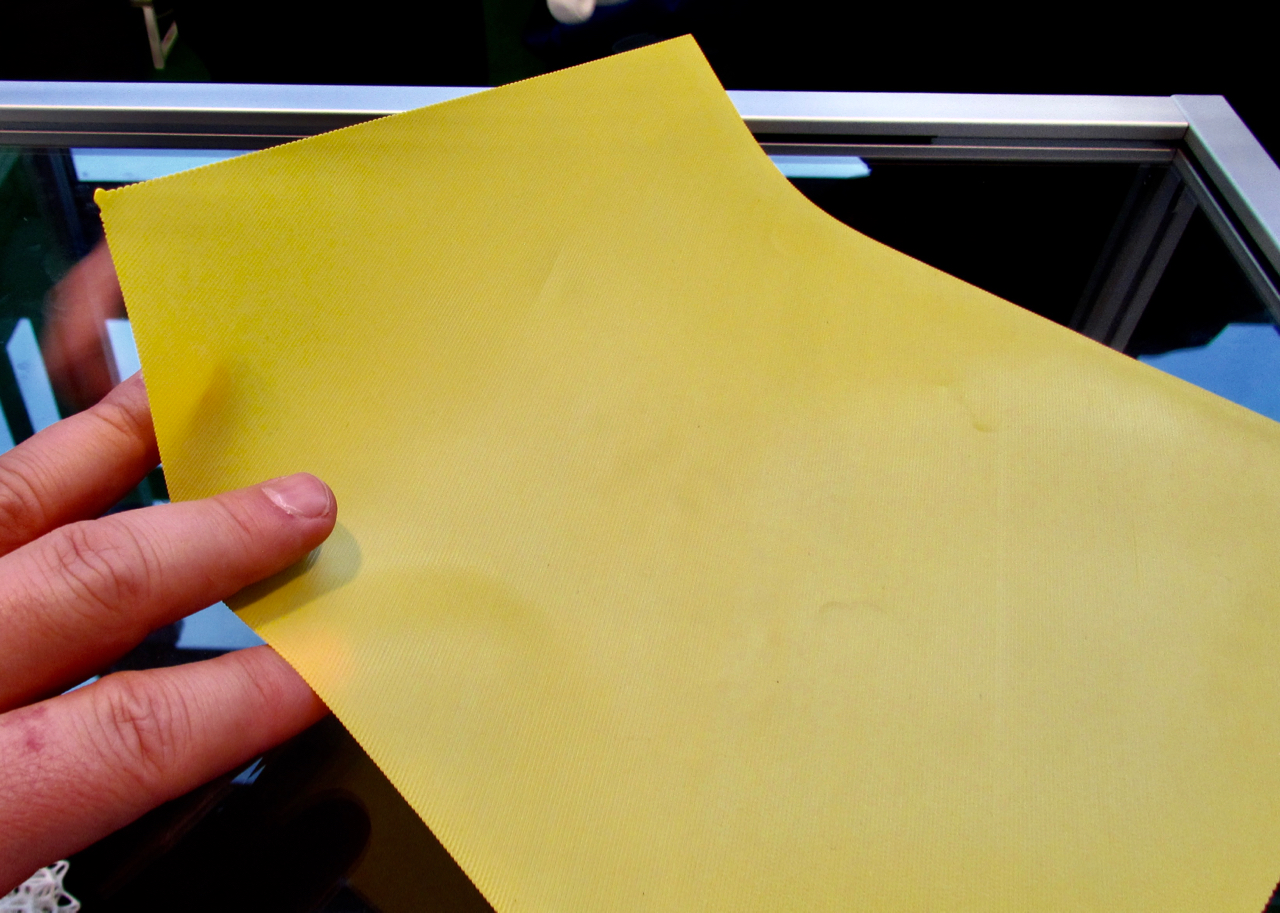

This calibration may seem significant, and it is. The results are spectacular. Check out their calibration test, which is a single layer extrusion over the entire print surface:

I found it hard to believe that this is possible, as the sheet was of consistent thickness over its entire surface. Yes, we measured it with calipers to ensure this was the case! There’s not many 3D printers that can do this right out of the box.

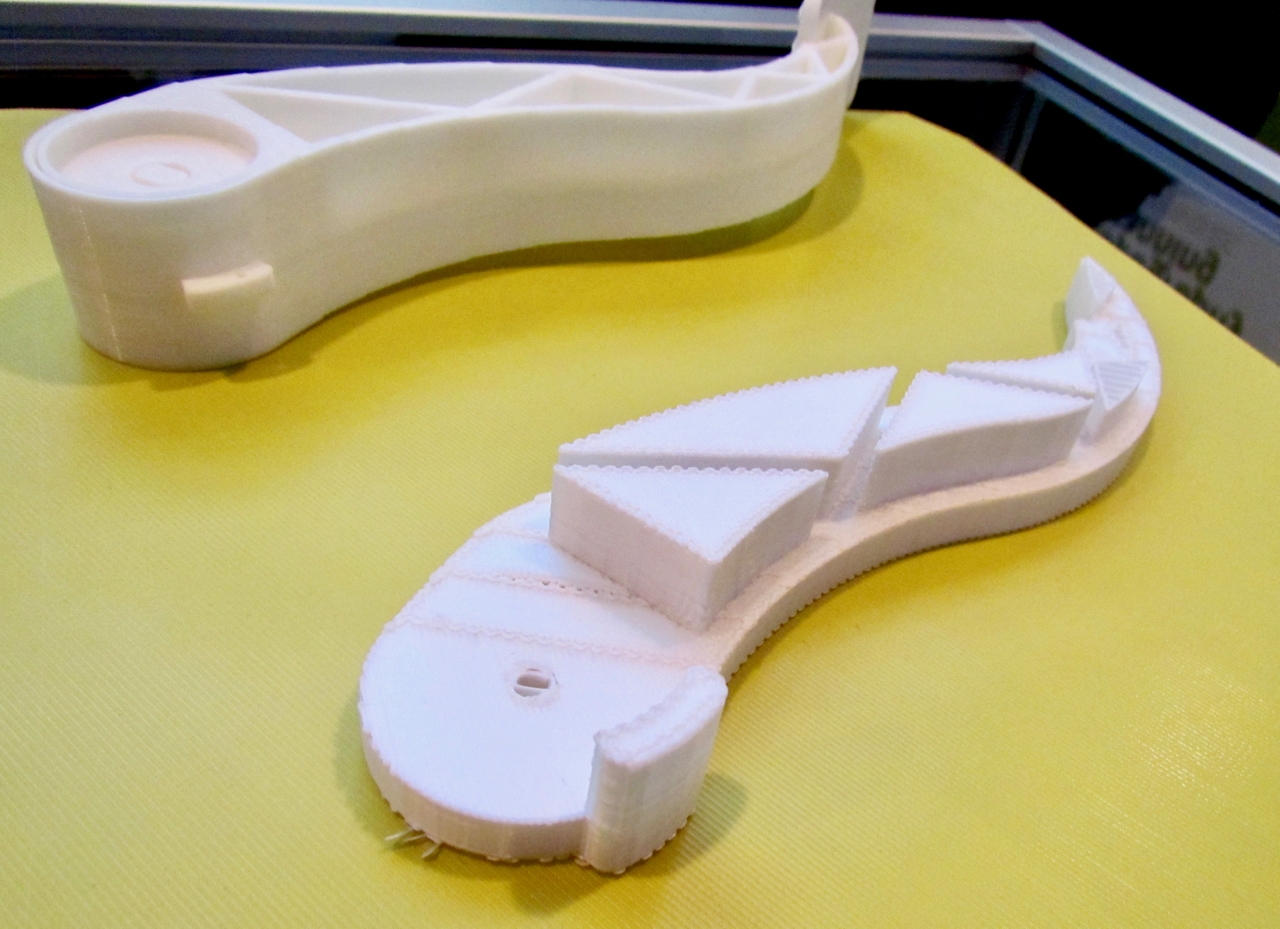

The second interesting innovation from the company is a support material called “Breakaway Support”. There are many types of support material, but this stuff is designed to be pulled off a print in an extremely easy fashion.

Consider this example of a part (at the rear) and the corresponding support material (at the front). As you can see, the support material was easily pulled right off the part with no fuss. This is fantastically faster than dissolving support or tediously picking off bits. However, breakaway support cannot be used in all object geometries, so the company does also offer a water-dissolvable support material as well. But I’d start with the breakaway material if at all possible.

The materials are designed to adhere to the print surface, yet easily pop off by twisting the build sheet after printing.

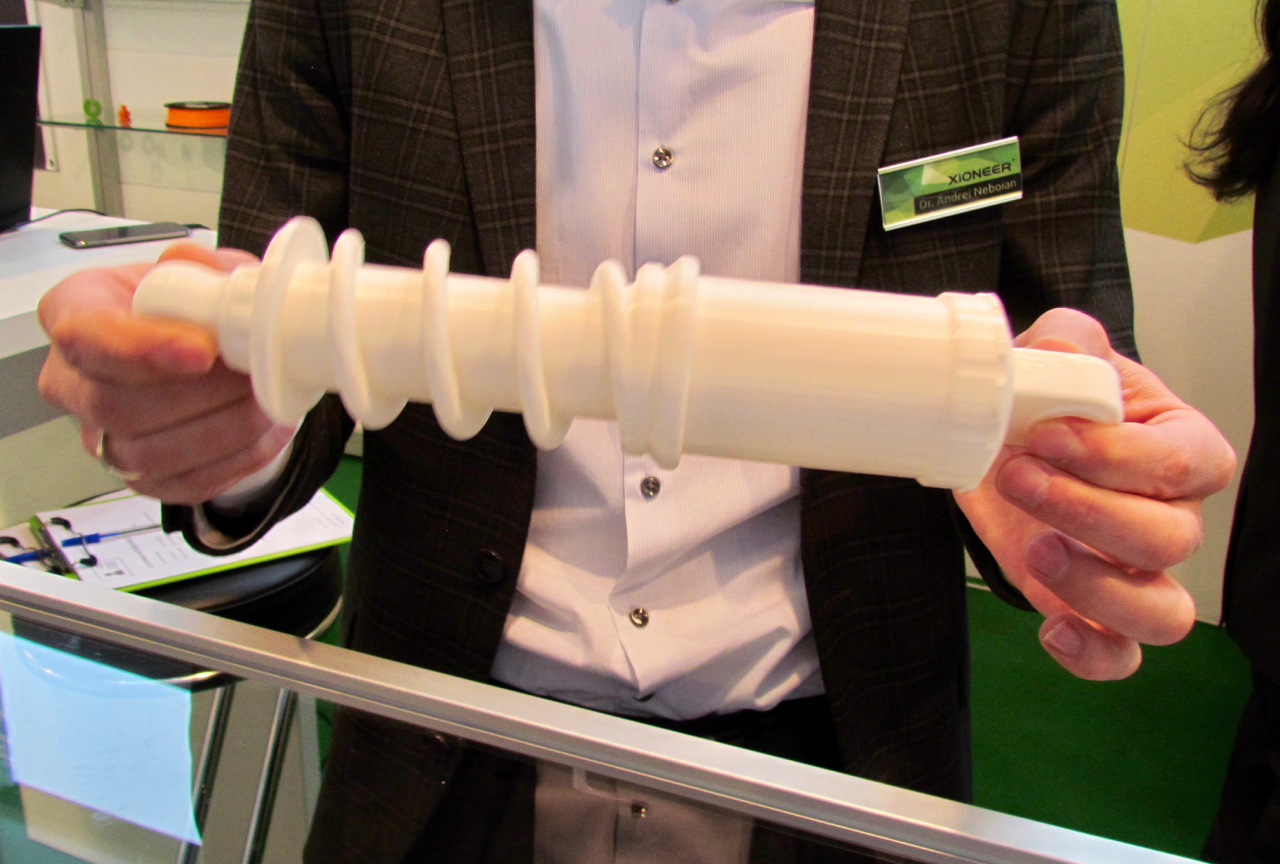

Here’s an example of a fully articulating shock absorber, 3D printed in one operation. After support removal, this object actually functions.

While there are those who will say a closed materials machine is not a good thing, I propose that Xioneer’s approach is worthy. Why? Because they seem to have taken full advantage of control over plastic chemistry, software parameters and mechanicals to produce a machine that can print very accurately and reliably without the need for operator tuning. That’s something many businesses would certainly pay for.

And how much will you pay? The X1, currently on pre-order for shipping in May 2017, will set you back €9,980 (USD$10,600). Materials are also slightly higher than generic pricing, around USD$100 for 750g, depending on what is selected. However, Xioneer does offer a materials refill system with somewhat lower pricing.

Via Xioneer