CEL makes some of the most interesting desktop 3D printers you can find, but now they’re even more interesting with a curious set of announcements today.

The company’s Robox 3D printer includes a number of very cool features not found in other machines, such as their innovative needle valve shown here, used to virtually eliminate drips and retraction issues:

The company has launched (via Kickstarter) three new products:

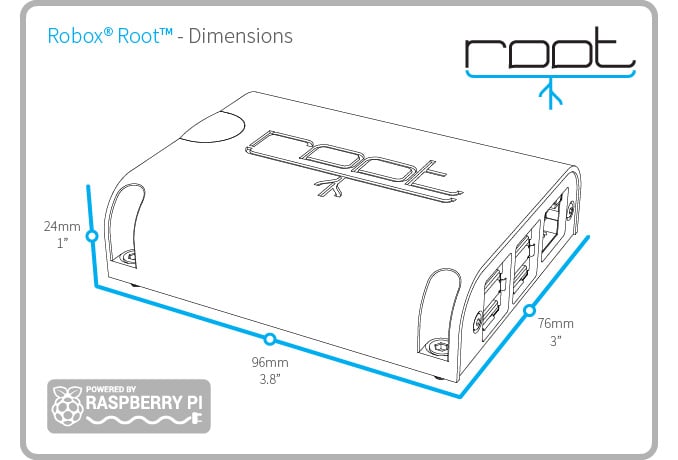

The “Root” is a “remote control device which allows users to share, control and monitor multiple prints via a wired or wireless network.” It’s a Raspberry-Pi powered set-top box that connects to a number of CEL Robox desktop 3D printers. This unit will transform a pile of independent Robox 3D printers into a single, manageable unit. A print farm, if you will.

The Root will enable a number of powerful capabilities, not the least of which will be to operate the machines remotely from any location. Problems can be detected and at least partially dealt with remotely. While you might not be able to be physically present to swap the filament, you could potentially restart the job on a second, available Robox printer.

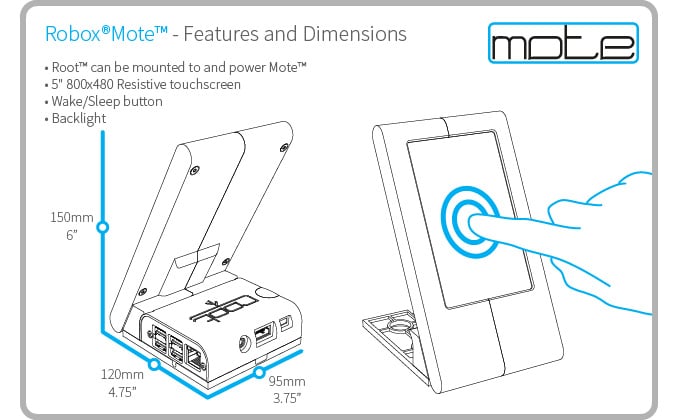

The “Mote” is a separate unit that provides a touch screen interface to the Root. It’s separate from the Root itself so that it can be more conveniently located for operators. This makes much sense. It also enables independent upgrades and maintenance of the two fundamentally different units.

The “Tree” is a vertical stacking system for Robox 3D printers. There are two models offered, a five-unit tall model and a three-unit tall model. These are custom-sized to perfectly fit a Robox 3D printer, as you might expect. They’re open air and thus enable easy hookup access.

Stacking machines is not a new concept, and I’m sure some CEL clients have already done so themselves with makeshift shelving systems. However, the Tree announcement makes it formal and likely will encourage the purchase of multiple Robox units. Good news for the company as it gives their clients a way to “vote with their wallet” by buying a squad of Robox’s in one transaction.

It also permits parallel operation, where up to five Robox’s can work on a single project at once, printing literally five times as fast – or at least with increased reliability.

CEL’s Kickstarter has a variety of product combinations and pricing for these products, which will no doubt increase at the close of the launch.

What’s interesting about this announcement is that it specifically addresses workflow. This is a phenomenon I’ve seen with several other companies, who realize that in order for businesses to more effectively use the equipment, there must be improvements to the activities required to do 3D printing. CEL has done some analysis of requirements and come up with this combination of improvements.

That seems to be one of the standard practices these days among the major manufacturers: focus a bit more on the workflow aspects and not so much on the 3D printing equipment itself.

Via Kickstarter and CEL Robox