This week’s selection is the 3D printable vise system by Pinshape contributor Christoph Laimer, a.k.a. “TheGoofy”.

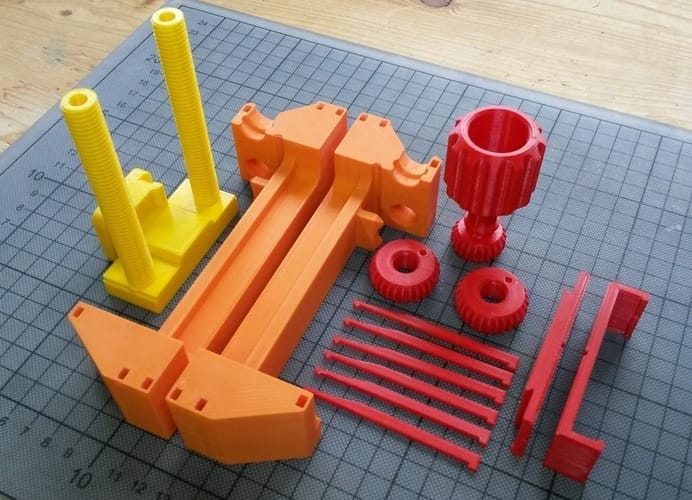

Zurich-based Laimer has produced an amazing 3D model that not only works functionally, but is entirely snap-fit together and requires zero additional components.

Laimer explains:

This is a quite robust 3d-printable machine vise. It’s 100% 3d-printed – no screw or other piece of hardware is needed to hold the individual pieces together. Pieces clip and snap together. It’s a demonstration that it is very important to consider forces and material properties already when designing a mechanical object.

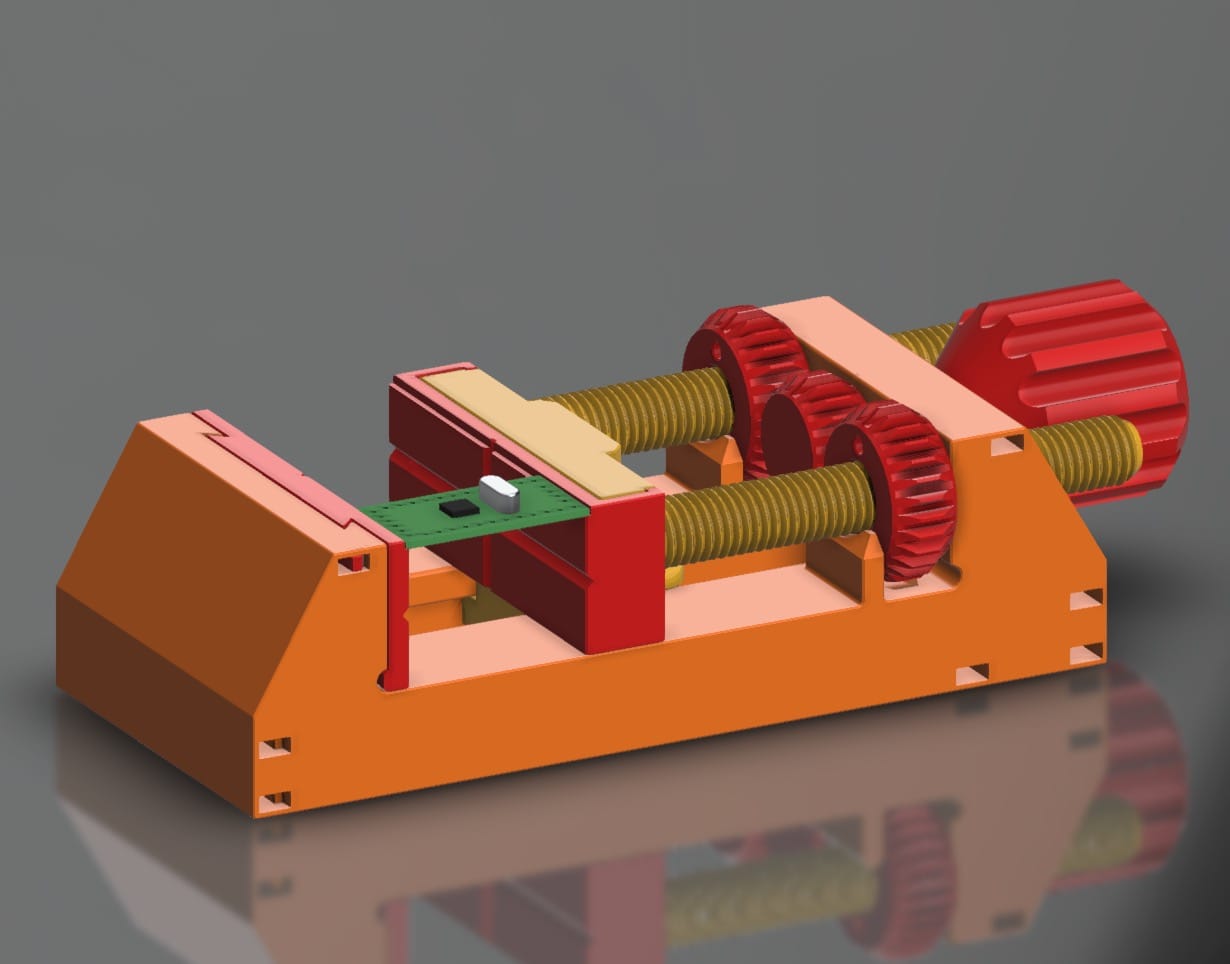

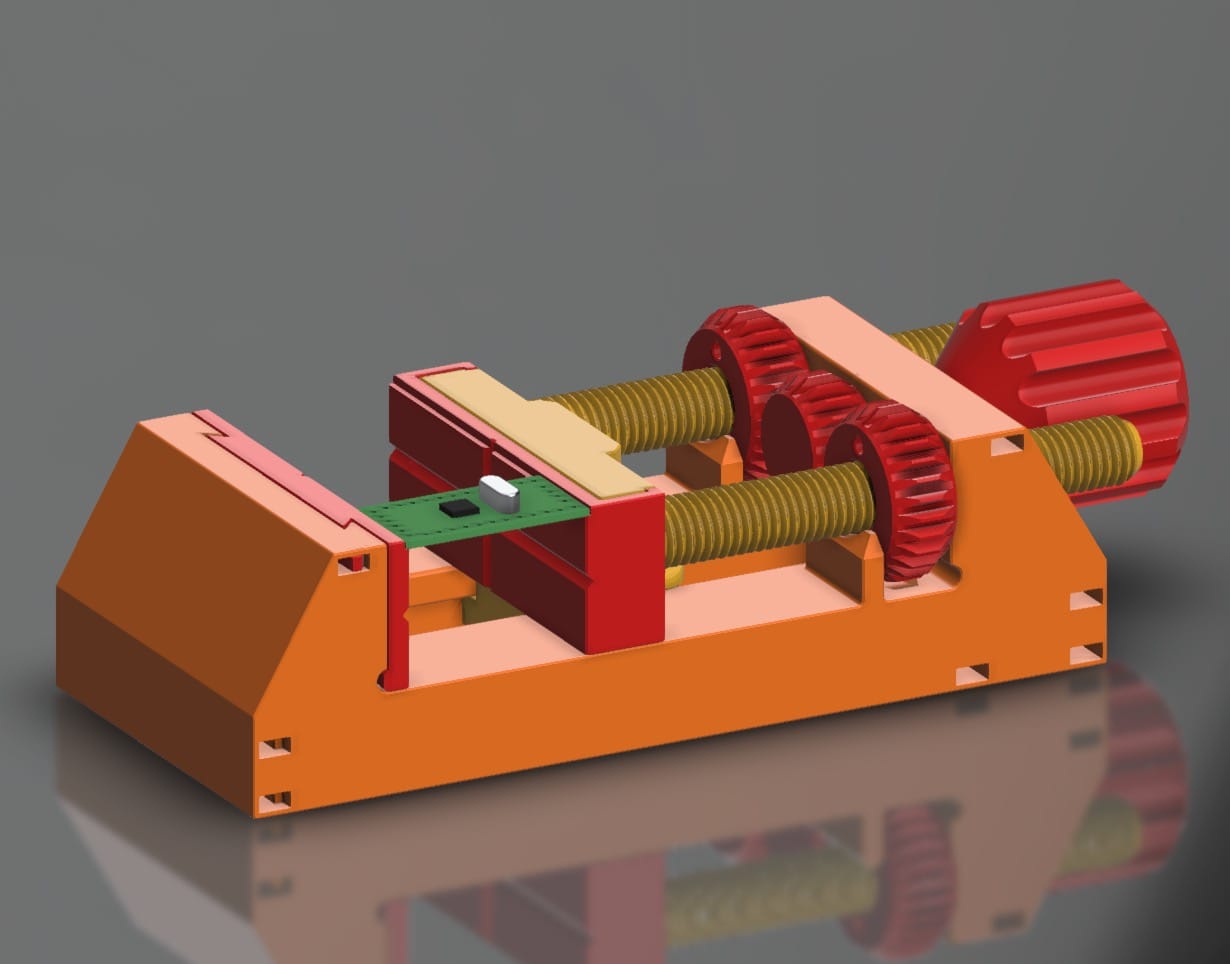

You can see a full color 3D representation of the vise design in this Autodesk Fusion 360 online view.

Laimer advises printing the 9 components with 35% infill only, but with three perimeter shells, with a layer size between 0.1 and 0.15mm. He also recommends using no support material.

The STL files are freely downloadable from Pinshape, a terrific site to find interesting 3D printable models.

But before you run off to print and assemble the vise, I strongly recommend you watch Laimer’s video explaining how to assemble the vise components. And it’s not because you need that explained: no, instead you will find an extremely valuable explanation of how best to 3D print not only these vise components, but ANY mechanical component on an extrusion-based 3D printer.

Laimer offers several other very interesting 3D printable projects that you can find on his website.

Via Pinshape and Christoph Laimer