I’m wondering if there is a product category being ignored by some 3D printer buyers.

For years one of the more popular 3D printing processes was (and is) the ability to print high resolution, complex pieces in powdered nylon. The process involves selectively fusing layers of nylon powder with a powerful laser, or Selective Laser Sintering (SLS). This process has been made most popular by 3D Systems and EOS, both of whom offer machines of this type.

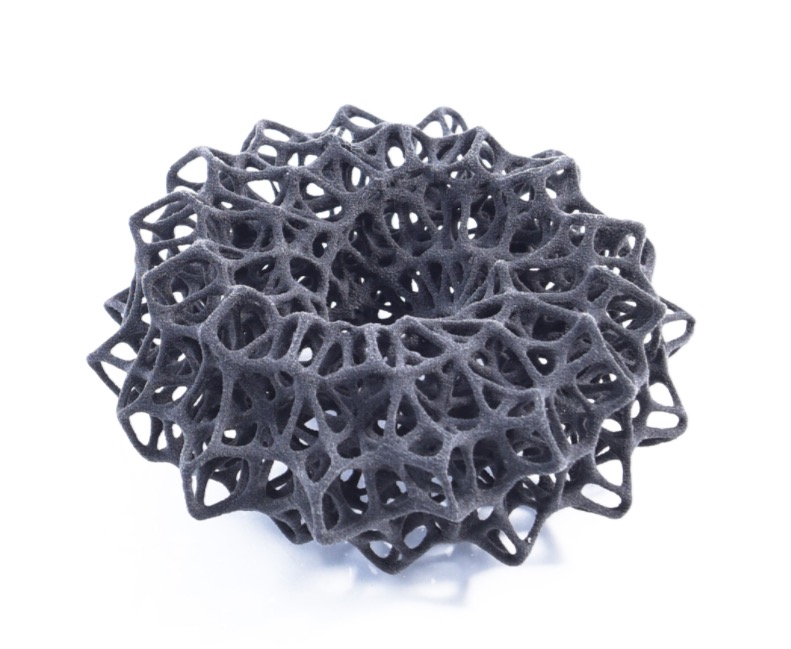

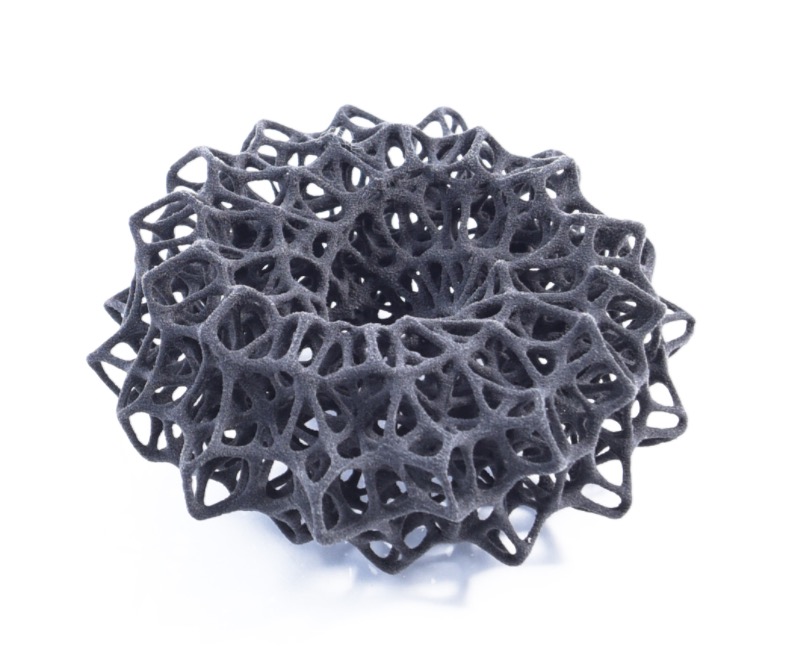

The benefit of nylon is significant: it is a very strong and durable material, yet is not particularly expensive. Combine that useful material with the ability to create literally any shape with it and you have a winning formula.

That ability comes with a cost, however, as such machines from EOS and 3D Systems have typically been fairly high, usually in the three digit thousands. For that price you receive machines that are nearguaranteed to work extremely well in a production environment. In fact, many 3D print services employ such equipment and literally run them non stop for years at a time.

However, if you are a smaller organization and don’t have the volume to justify the acquisition such equipment for your own workshop, then you have some choices to make.

One choice might be to engage a 3D print service provider, where you can “pay by the print” and use these commercial machines by proxy.

However, that might not be an option for some companies, who may have concerns about print shipping times or even security concerns about who is seeing the prints.

If there is a reason for not using a 3D print service and an inability to afford the typical equipment, what is one to do?

There is a new option that seems to be emerging for such situations: low cost laser sintering equipment.

There is now a class of 3D printers that use more or less the same type of SLS printing process, but have far lower price tags attached to the equipment. These machines may not be suitable for a decade’s worth of 24×7 production, nor have as large a build volume, but they will certainly fit within the usage envelope of many companies.

One example of this category is Sintratec, who produce two such machines. Their “Sintratec Kit” is perhaps the lowest cost option in the category, with a charge of only €4,999 (USD$5,375) for a assemble-it-yourself nylon printer that actually works well. If assembly is not in your playbook, their Sintratec S1 is slightly more expensive and offers more capabilities.

For those organizations wishing to operate their own nylon powder printing system, there are answers, whether you’re large or small.