There hasn’t been much change in the standard diameter of 3D printer filament for years now, but perhaps that’s going to change.

In the early days of desktop 3D printing, many printer developers had to use repurposed polymers, such as welding wire. This material came in certain diameters and became a standard in the early industry at 3mm. Later on it was discovered that 1.75mm diameter filament had some advantages depending on the configuration of the machine, and it became quite popular.

Now it seems that someone is developing 5mm diameter filament.

One of the larger makers of 3D printer filament is Toner Plastics, who as we learned a few years ago, is one of the major suppliers of white-label filament to many resellers. They’ve been supplying the industry with a wide variety of polymer products in a number of formats. Along with 1.75 and 3.00mm diameter filaments, they also provide spools sizes of “1 lb, 1 kg, 5 lb, 10 lb, 25 lb and more”.

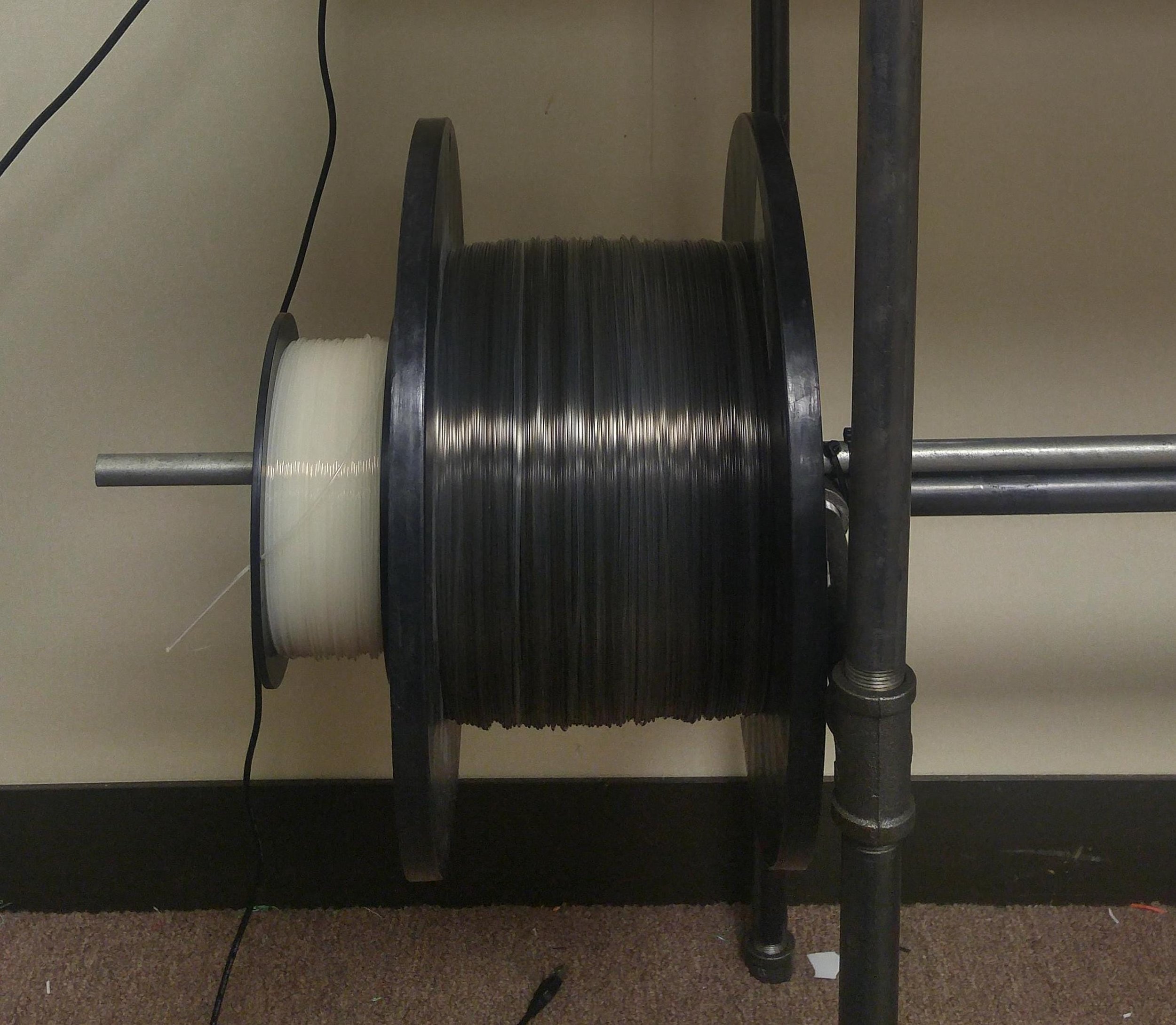

But now I’m reading a post where they show a spool of what is said to be 5mm diameter filament, image at top. It’s a bit hard to see the size here, as we don’t know the size of this spool (a banana in the view would be handy!) I suspect this is a rather large spool.

Here is a view of another 5mm spool right beside a 1kg spool and the size difference is quite clear. Apparently they can produce 5mm filament in spools up to 30 lbs (13.6 kg). That’s a very large spool!

I am skeptical about this approach, at least for certain types of plastics. Why? Because the thicker the filament, the less flexible it becomes. I’ve had plenty of 3mm filament cracking due to lack of flexibility.

However, it’s possible that for some filament mixes this would work, as a somewhat flexible material might bend sufficiently for spooling at that diameter.

Another interesting possibility is using very flexible material in this way, as one of the ongoing issues with flexible filament is that it cannot be easily 3D printed on many devices: it bends like spaghetti before reaching the hot end. A thicker filament could solve that, and still have a very flexible print.

But that’s not what this material is for. According to the poster from Toner Plastics:

I do not have the exact details on this one, but this filament is being developed for a customer of our who makes large format printers. I know I am certainly looking forward to seeing how this runs on their machines. It’s a different approach than using a pellet feeder for the extruder on high output printers.

And this tells us something interesting: All of the high volume 3D printers I’ve seen under development appear to be using the pellet approach because it can achieve faster print rates. Much faster, in fact. Here we see some unnamed company attempting to achieve the same high print volume with a different approach.

While this may be technically possible, I’m not convinced this is a good idea, because the cost of filament is vastly greater than plain pellets. And that cost differential is going to be even more dramatic if you are printing large objects, which seems to be the intent here.

Via Reddit