As the second largest sector for additive manufacturing (AM) applications, aerospace continues to be a key industry for AM machine manufacturers and service providers.

French 3D printing company Prodways has just secured an important partnership in this field, potentially testifying to the firm’s role in the overall AM market.

Prodways, a subsidiary of Groupe Gorgé, recently announced that it will be partnering with Safran, one of the largest aircraft engine manufacturers in Europe, to expand its technological capabilities. To learn more about the deal, ENGINEERING.com spoke to Groupe Gorgé CEO Raphaël Gorgé.

Prodways and Safran

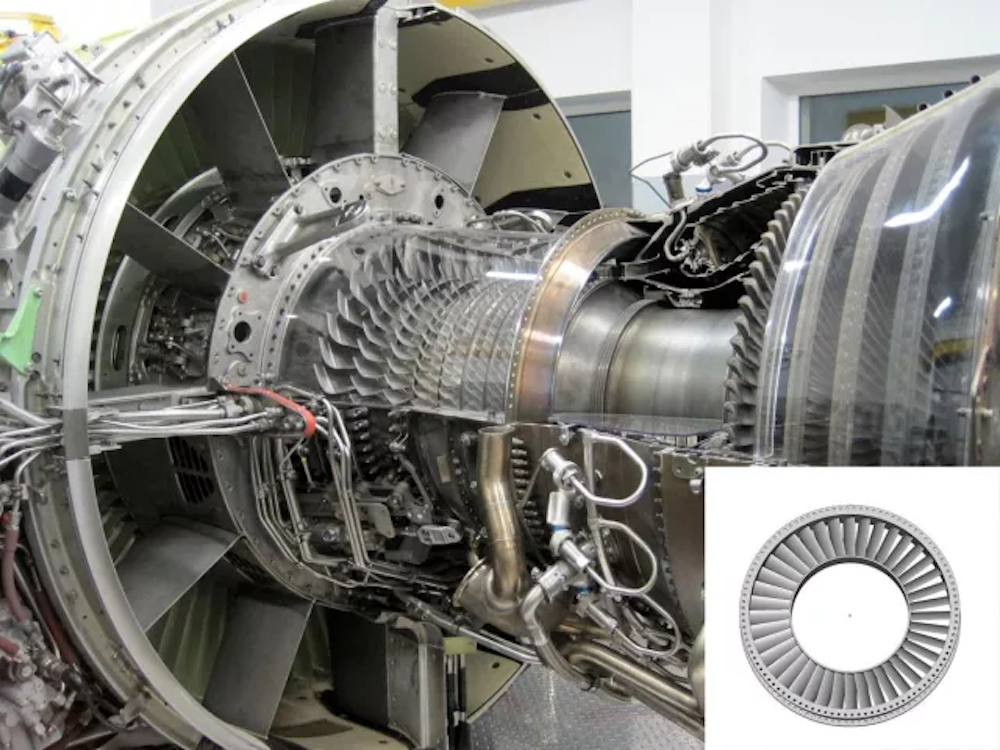

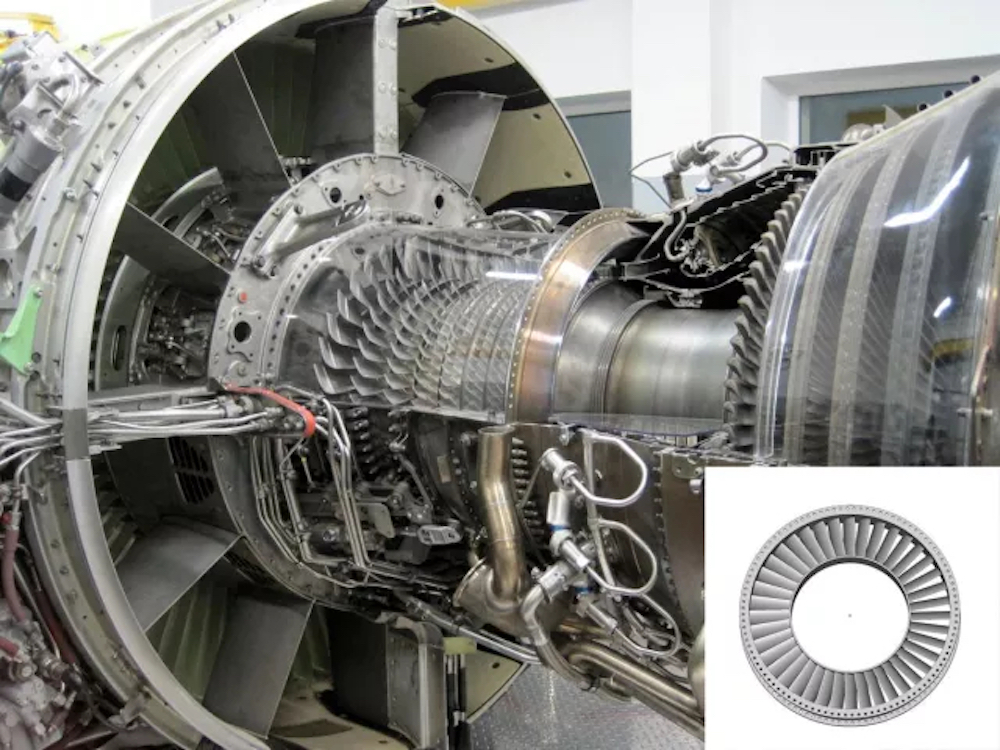

In the 3D printing world, Safran is best known for its work with GE. Through joint company CFM International, Safran and GE developed the 3D-printed LEAP jet engine nozzle, which will be installed on engines for a number of new aircraft.

While the LEAP nozzles are produced directly via selective laser melting, the French engine maker will also expand the capabilities of indirect metal part production via 3D printing. Safran recently signed a technological partnership agreement with Prodways that will see the advancement of Prodways’ 3D printing technology for the production of metal parts through indirect casting processes.

In addition to manufacturing machines and materials for 3D printing, Prodways provides industrial AM services. The company’s primary technology is called MOVINGLight, which features a digital light projector (DLP) mounted above a vat of photosensitive polymer resin used to harden large swaths of material into physical objects. As industrial machines, Prodways’s MOVINGLight systems are capable of high-throughput, making them ideal for large batch production.

According to Gorgé, Safran has been a customer of Prodways’s part production services for about ten years. “Safran thought that the applications of MOVINGLight for casting, ceramics and other applications had interesting advantages in terms of accuracy and productivity,” Gorgé explained. “So, Safran decided to take our work together one step further. The aim of this partnership is that the company will open up a little bit more about its technology roadmap and, then, together we can focus on the most promising applications of Prodways’ technology.”

“For us, the partnership represents a very strong recognition,” Gorgé said. “As you know, the aeronautic industry—specifically aircraft engines—is one of the most promising fields for the applications of AM. The fact that Safran has decided to work with us is obviously a strong recognition.”

Read more at ENGINEERING.com