We had a chance to speak with two individuals at 3DEO, a promising 3D metal printing startup.

3DEO produces a 3D metal printer with an unusual – and new – process that should prove effective and economical for users.

We spoke with Matt Sand, President of 3DEO and Lance Kallman, VP Business Development.

Fabbaloo: How did 3DEO get started? Who was behind it?

3DEO: Matt Petros and Payman Torabi completed their doctoral degrees in mechanical engineering from the University of Southern California when they teamed up with Matt Sand to start a 3D printing company.

The company initially started as a consulting company, but after a few weeks they had an idea for a low-cost metal additive manufacturing technology. This initial idea would ultimately become Intelligent Layering.

Fabbaloo: I know that your process is a bit secretive, but what can you tell us about it? How does it work, in general terms?

3DEO: While there are some very important elements of our technology that we keep confidential, we are always excited to talk about it and explain the capabilities.

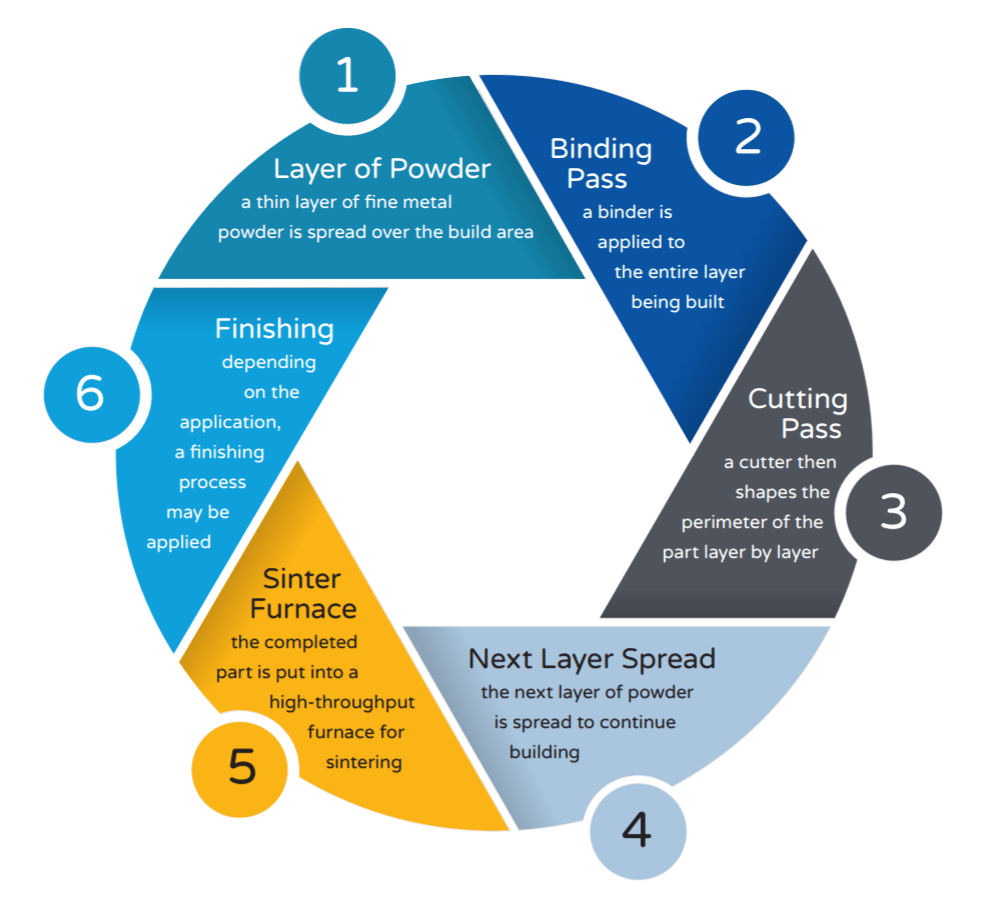

Our process begins with spreading a thin layer of fine metal powder over a build tray. We then use a low-cost spray head to spray a liquid binder over the entire build area. Now with a fully bound layer, a CNC end mill is used to cut the perimeter and internal features of the part being created for the given layer. The process is repeated until a 3D green part is fully formed.

The green part is then put into a sintering furnace to achieve a high density of greater than 99%. While the surface finish as-sintered is excellent, there are still a variety of post-processing available including hot isostatic pressing, plating, polishing, and heat treating.

Fabbaloo: Will your technology be deployed as service or as standalone equipment for sale to clients?

3DEO: We are a parts supplier, so we deliver production parts directly to customers. In our experience, many customers would prefer to buy parts to machines, so we are working to become a world-class manufacturer. In addition, we keep the technology in-house to ensure the highest part quality possible.

Fabbaloo: What part quality have you been able to achieve, and is it sufficient for industrial use?

3DEO: Part quality is one of the greatest challenges with additive manufacturing today, especially when it comes to parts being qualified for different industry standards. 3DEO was founded with this in mind, which is why we tied our process an existing industry standard for metal injection molding (MIM).

MPIF Standard 35 has been an accepted standard for four decades and requires metal parts to adhere to a chemical composition and material properties specification. Our parts meet MPIF Standard 35 and can achieve over 99% density because we use a MIM powder, a MIM binder, and a MIM sintering furnace. The obvious benefit is that we can immediately go to market with production parts where the MPIF standard is accepted.

Fabbaloo: How does the cost of your materials compare with other 3D metal printing processes?

3DEO: In general, 3DEO’s part cost is 60-80% below competitive metal 3D printing technologies. Many 3D metal printing processes require very expensive powder that costs $100-200 per pound (due to requirements such as monodispersed distributions).

3DEO was created with the guiding principle that everything must work to lower final part cost, and the metal powder is no exception. We use MIM powder without any modification, which means we benefit from the established competitive powder supply chain.

For example, our 17-4PH powder costs less than $10 per pound. When combined with an ultra-low machine cost, the final part cost is dramatically below anything currently seen in metal additive manufacturing.

Fabbaloo: How are you funded? Are you profitable yet?

3DEO: 3DEO was initially funded through a Small Business Innovative Research (SBIR) grant from the National Science Foundation (NSF) in 2016. Today, 3DEO is grateful for its continued involvement with the NSF and to be a partner with one of the largest scientific seed funding organizations in the world. 3DEO is also privately funded.

Fabbaloo: What is your business development strategy? Are you targeting particular markets and industries?

3DEO: Our business development strategy is to pursue high-volume applications. Since our technology is very repeatable and low-cost, we see a terrific opportunity to be the leading high-volume metal 3D printing company.

Our niche exists at volumes greater than prototyping and below the breakeven point achieved through high-volume traditional manufacturing. We are currently printing production parts in 17-4PH stainless steel and working with customers across a broad range of industries, including automotive, medical, dental, oil & gas, and power generation to name a few.

Fabbaloo: What is your plan for growth? What’s next?

3DEO: We plan to continue our fast growth and to scale according to customer demand. From our current vantage point, there is pent up demand for low-cost metal 3D printing. According to PricewaterhouseCoopers, the #1 barrier to widespread adoption of metal 3D printing is cost. We plan to unlock this potential with our reliable, low-cost technology.

Via 3DEO