3D printing at the nanoscale isn’t new, but its applications are still being discovered.

When the process, known as two-photon lithography, first began making headlines, many of the demonstrations involved the fabrication of aesthetic models: microscopic race cars, space shuttles and even ancient Roman sculptures.

However, researchers have also been applying the technology to the field of medicine. So far, the results have been somewhat limited, from a mechanical standpoint. For instance, one team has coated the tips of 3D-printed “sharks” in iron in order to guide their movements with magnetic fields. Other groups have worked on developing new geometries that can be beneficial in increasing the surface area of drugs used in targeted delivery.

These studies do demonstrate the potential for nanotechnology in some applications, but, in some ways, the objects printed are the same aesthetic objects with some added medical superpowers. Mechanically, there have been few examples of true micromachinery. That is, until Roberto Di Leonardo, a physics professor at Sapienza Università di Roma and at NANOTEC-CNR in Rome, developed a series of micromotors, which are powered by bacteria and ordinary LED light.

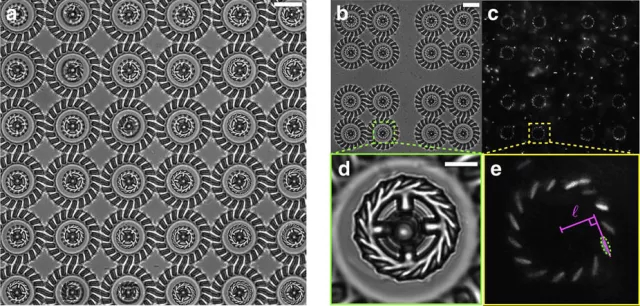

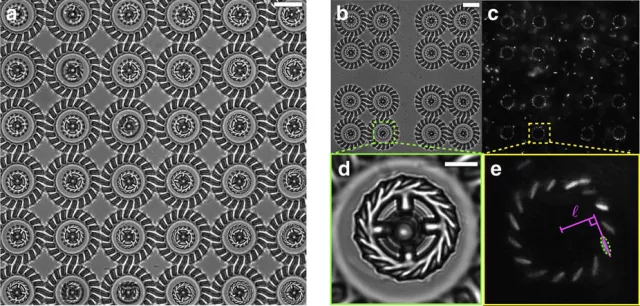

In the experiment conducted by Di Leonardo’s team, you can see the beginning of what could be the future of micromachines, including a series of 36 micromotors rotating in unison.

“The main idea for the experiment comes from the observation that using modern tools of nanotechnology and microfabrication, we are becoming better and better at fabricating at thobjects e microscale,” Di Leonardo told ENGINEERING.com.”[Using 3D printing], we can build any shape, but it’s much more difficult to bring these structures to life by building motors and actuators. We’re not as good at building micromotors, especially if we want these micromotors to be autonomous.”

3D Printing Micromotors

Di Leonardo’s lab actually constructed its own two-photon lithography system, which uses a high-powered laser to direct two photons of near-infrared light in ultrashort pulses at a photocurable resin. Unlike commercial nano 3D printing systems, like those from Nanoscribe, Di Leonardo’s team introduced a special modulator to the setup, making it possible to split the beam so that it can selectively cure multiple areas in parallel. This essentially makes it possible to 3D print the same object en masse, as was the case with the 36 motors printed in his study.

3D printing is not the only technology that can be used to create microscopic assemblies; it just happens to have the benefit of being able to produce fully assembled systems, such as the motors demonstrated in this study. Unlike other forms of 3D printing, two-photon polymerization has the benefit of 3D printing objects in a semisolid resin, making it possible to create complete assemblies. However, Di Leonardo said that there are other tools for assembly, including holographic optical tweezers, that make it possible to manipulate tiny objects with laser light.

Read more at ENGINEERING.com