Germany-based ACEO offers powerful 3D silicone printing services.

Silicone is one of those elusive materials that can be 3D printed, but only be a select few companies and their technologies. One of them is Wacker Chemie AG, who produce the ACEO silicone 3D printing process.

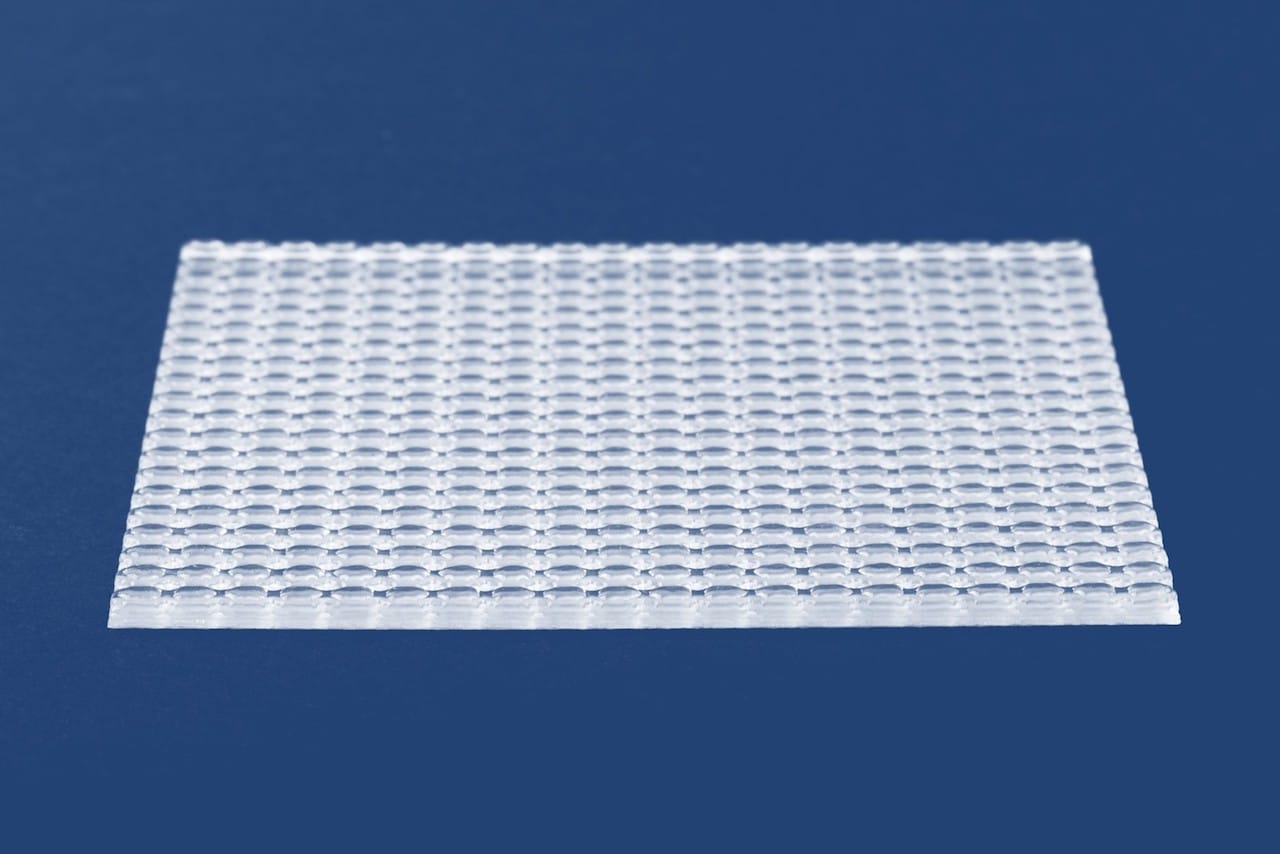

It’s a liquid-based process in which individual voxels of material are created by selectively dropping them from a nozzle, and then applying a dose of ultraviolet light to solidify the material. It seems a bit similar to Stratasys’ PolyJet technology, but in this case the material is actually silicone.

Silicone is highly versatile material, as it can exhibit a number of properties, depending on the specific mix. ACEO lists these possible characteristics:

- Temperature range from -50C to +300C

- Radiation resistance

- Transparent

- Biocompatible

- Varying degrees of flexibility and hardness

And even better, the ACEO process can produce silicone prints in a wide range of colors – I presume they do so by simply coloring the liquid material before printing.

The silicone material is ridiculously tough, as can be see in this demonstration video with an incredibly transparent 3D silicone print:

But traditional methods of producing silicone objects are somewhat limited, and the ability to 3D print objects offers the possibility of creating objects that have never been seen previously. However, this requires considerable creatively on the part of the industrial developer, who more than likely has never had such capabilities without 3D printing technology.

To counteract this effect, Wacker Chemie has established a workshop program, in which product developers can obtain direct access to ACEO 3D silicone printing experts in their facility. The goal of these workshops is to understand the requirements and see if they can actually be done using 3D silicone printing with ACEO technology.

I believe this is an excellent approach for introducing a radically new approach to a company’s staff, who otherwise might take a substantial amount of time to properly learn how to produce effective silicone prints – and also to inspire their creativity in using the new (to them) 3D silicone printing technology. There’s nothing like using things “hands on” to learn quickly.

Wacker Chemie offers 3D silicone printing services, where you can upload your design and have them produce it with their ACEO technology-equipped devices.

Finally, the company also offers the ability for clients to discuss projects that might require unusual silicone compositions; their experts would be able to determine how best to go about such projects.

Via ACEO