This week’s selection is the fabulously designed Spool Holder for Prusa i3 MK2 by Martin Majewski.

I know what you’re thinking: yet another simple spool holder, of the zillions that have been published. That may be true, but this spool holder is indeed very special; it is perhaps the best designed spool holder I’ve ever encountered.

Majewski, a German engineer, created the holder out of necessity, as most designs are, but applied his considerable design skills to the tasks. It incorporates a number of extremely useful features that demonstrate how a design can be made “good”.

What makes this design good? Let me list the ways:

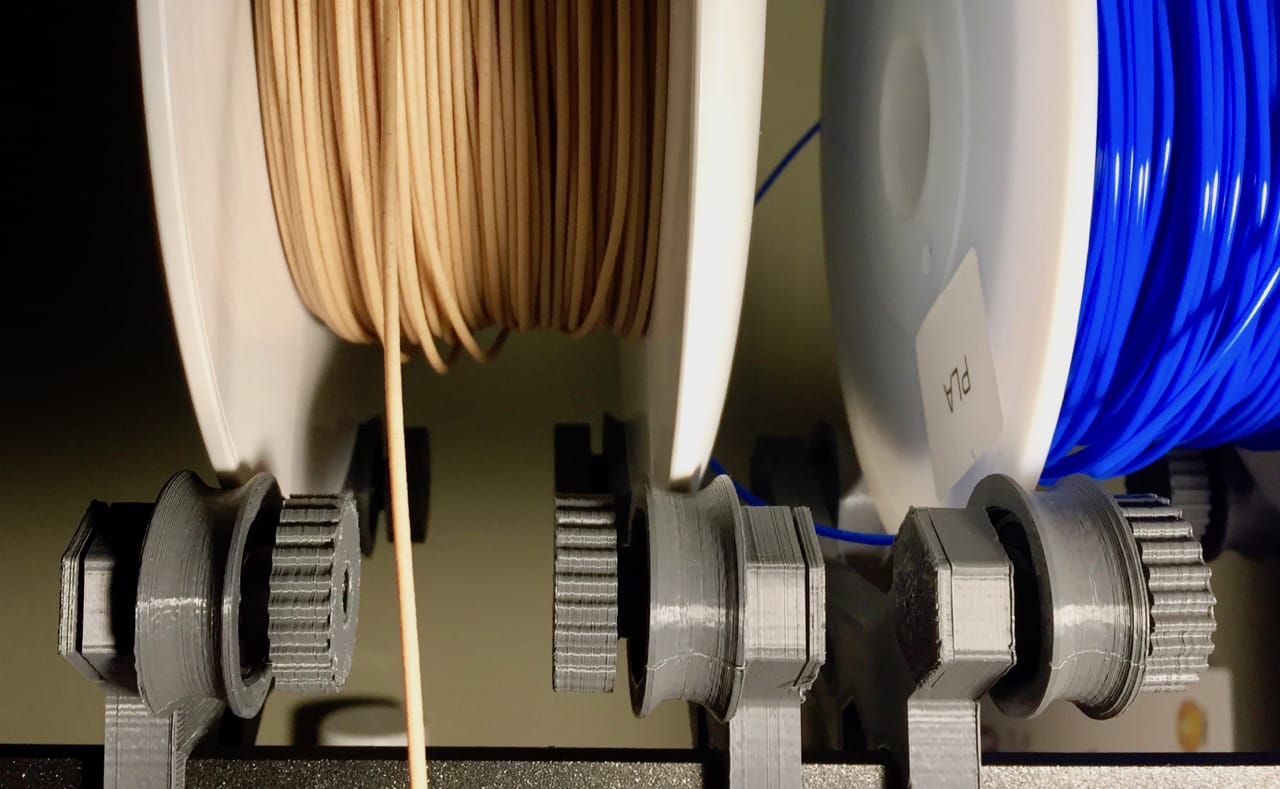

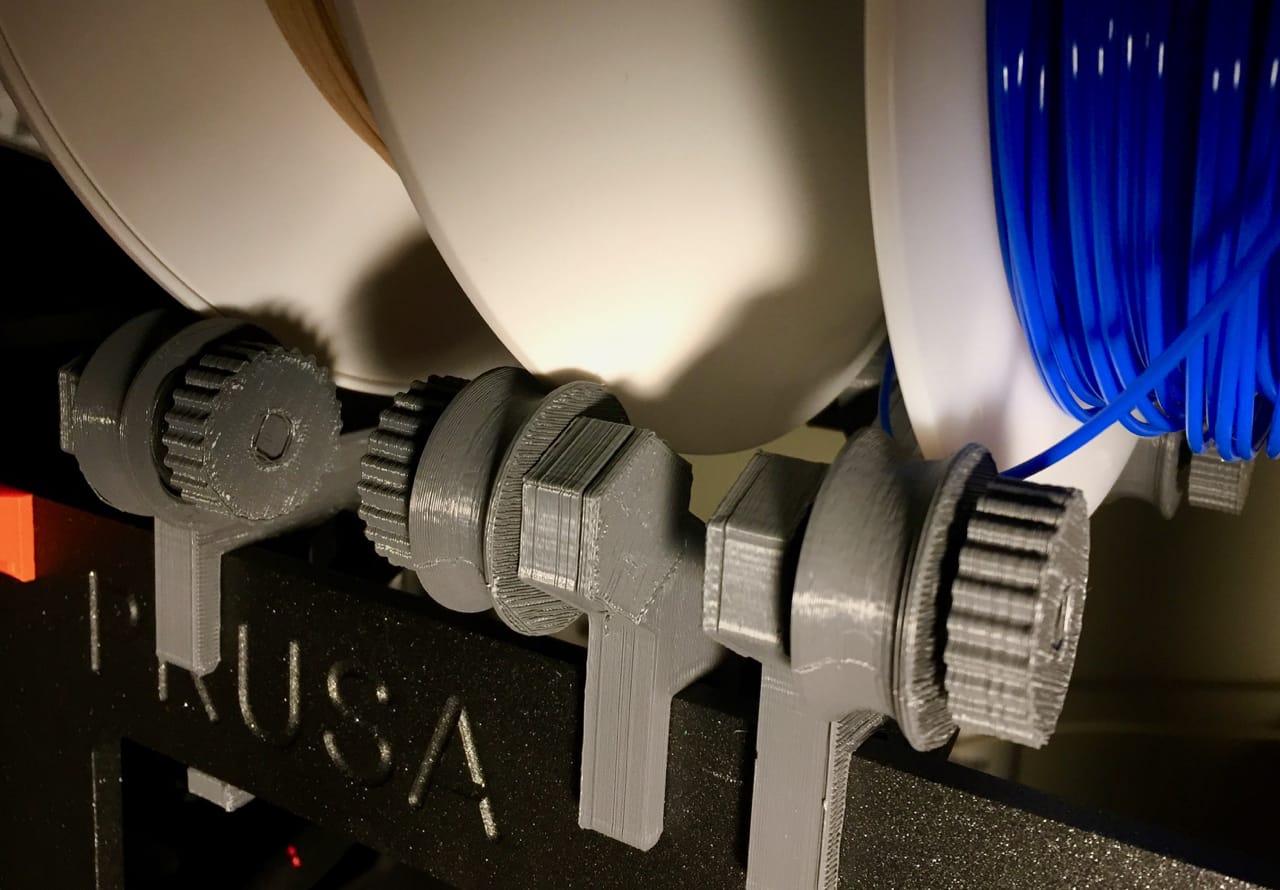

There is no hub required to hold the spool, unlike virtually all other spool holder designs. The spool simply sits on its edges. This means that almost any spool size can be instantly accommodated, and you’ll never have to worry about the size of the hub diameter, for example.

Usage is unbelievably simple: just place the spool on the holder and it’s done. You cannot make this any more straightforward.

The design is more than strong enough to hold full 1kg spools and could likely handle even heavier 2kg spools if required.

Due to the addition of actual bearings, the spool will turn very easily and snags are definitely not expected.

The design minimizes interference with printing operations, even though it is positioned quite close to the moving extruder.

The spool is mounted very firmly, yet is easy to install and remove without effort. You can swiftly accommodate larger or smaller spools by shifting one of the sides.

It requires no tools to assemble; it’s entirely snap together, except for two bolts that can be tightened by hand due to the large grippy nuts designed specifically for this purpose.

The spool holder is easily 3D printed and requires no support structures.

You can tell I very much like this design; I cannot imagine how it could be improved.

I mentioned that this project requires bearings, and they are of course not 3D printed. You’ll have to go shopping for them. The specific bearings required are standard 608 bearings, most frequently used by skateboards.

This means the best place to find them would be your local skate shop, and that’s precisely where I went to find a set. It was a bit odd, walking into a skate shop, as I am not a skater. I saw some skateboards, helmets, but mostly clothing on display, and it definitely did not look like a place where you’d buy parts. However, upon asking, the clerk was quite helpful and explained that “many” people drop by looking for bearings, and it seemed like a major product for this operation. I’m sure the clerk had no idea what these bearings were being used for.

I did encounter one problem when assembling this project, and that was the bearings can be a reasonably tight fit and you may require pliers to push them all the way in. However, it’s quite possible that they can be installed by hand in many cases.

There is one “issue” with this design that’s a bit different: it’s specifically for the Prusa i3 MK2 model, and will not work on other devices. However, I suspect the design could be easily adapted for other devices by adapting the mounting structure.

But more importantly, this design should inspire others to consider how best to create designs that optimize the use of the object, rather than just the printing of the object.

Via Thingiverse and Martin Majewski