We sat down with XJET’s CEO to find out where the new company is positioned today.

XJET produces a fascinating multi-purpose 3D printer that’s based on liquid inkjet technology. In XJET’s process, nano-sized material is encased in a liquid droplet that is deposited by a moving inkjet head to gradually form layers of an object. Post printing steps remove the binder and solidly fuse the material together to complete the object.

I find their technology extremely interesting because it has several key properties:

- Very high resolution, due to the particle size and inkjet technology

- The ability to 3D print many different kinds of materials

- The simplification of the process by separating the fusion process from the printing process

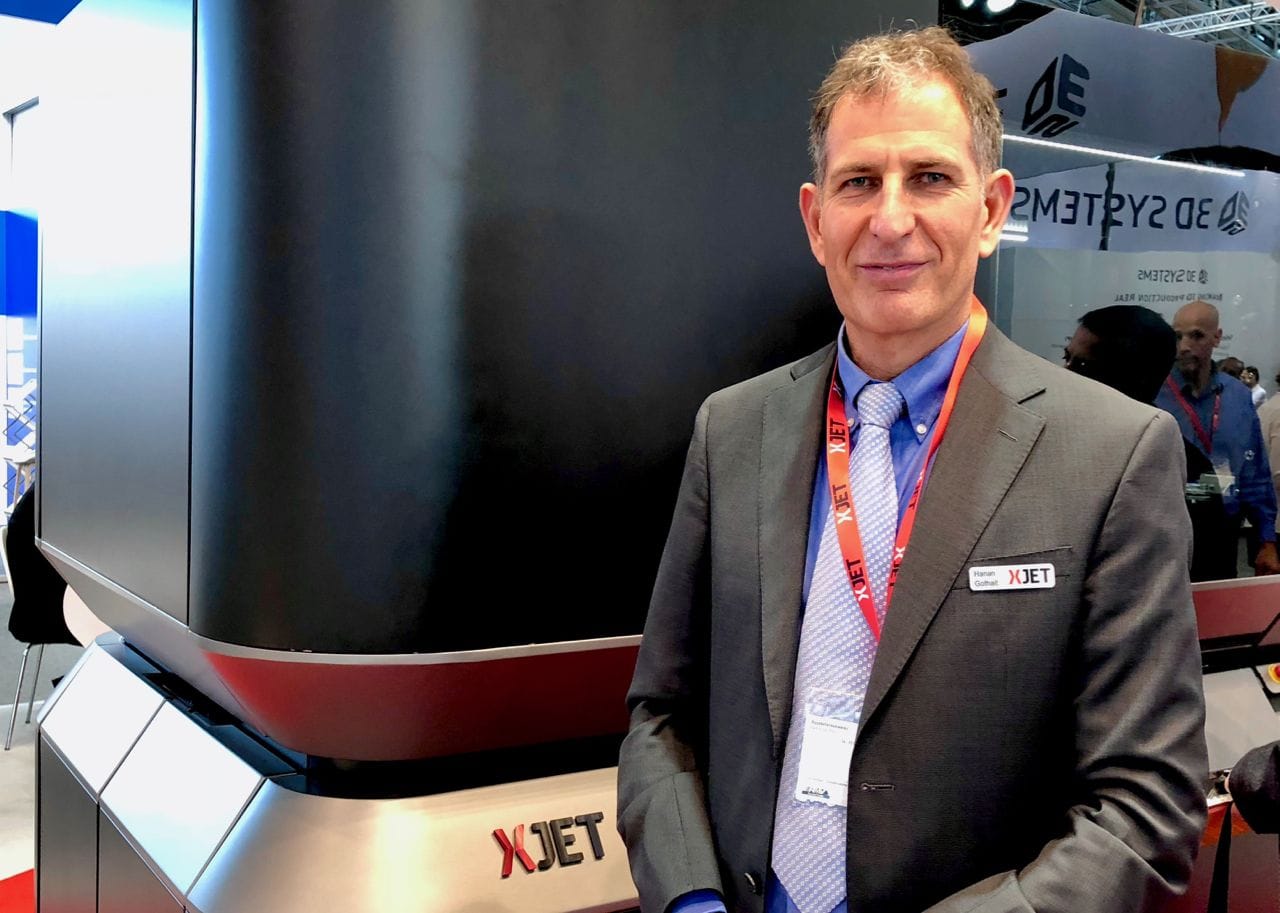

But at this point they’ve just launched their first machine at a customer site, so while at FormNext we spoke directly with Hanan Gothait, founder and CEO.

Fabbaloo: You’ve shipped the first production machine. What have you done internally to prepare the company to be production ready for clients.

Hanan Gothait: First, we’ve shipped the machine to Oerlikon [a 3D print service]. We’ve been working the lab for the past many years in order to make this technology work.

We are the first ones to do metal material jetting. We are jetting the material; we’re not doing lasers or powder, we do it without doing glue or binder. We are actually jetting material directly. So we’e been working in the lab, I would say 60 people, smart PhD’s, for six-seven years in order to make it work. Once it started working, 18 months ago, we started looking for first customers to launch the product.

We’ve done a lot of work in ink production, the material production too. We put people in for customer support. Hiring people, and training them. It’s extremely important for us to have happy customers, working customers. The first customers are the most important, the first 30 customers. We really treat them personally in order to make it a big success. Later on we will expand and have more and more people to copy the same ideas into additional customers.

Fabbaloo: The first customers will be your references for your future customers?

Hanan Gothait: Absolutely! First customers, we will be working closely with them. Many people will want to buy quickly, but we are choosing them carefully, based on our ideas of how closely we can work with them. We could sell so many more, but we are going slowly.

Fabbaloo: That’s very wise. Last year we were here and we saw the XJET machine and you were talking a lot about metal. Then when the first machine came out it’s talking about ceramics. What happened to metal?

Hanan Gothait: Metal: we continue and we will introduce metal probably next year. We had a lot of interest for the past years both ceramics. People really want to do ceramics and start working on certain applications. And we saw that we are able to introduce ceramics much faster than we originally anticipated. In the lab we had several materials going in parallel, which is much faster. But also the interest from specific applications in the market (which we cannot disclose to you now). But some of them are really rushed to us. So we saw a great match and said, let’s do ceramics first. Metals, many metals, will be introduced next year and the year after. We took the privilege would be a little flexible with these companies. We said, let’s go faster with ceramics and do the metal later.

Fabbaloo: You were matching customer demand to your product?

Hanan Gothait: Yes, and also our R&D and product development capabilities. We saw that it’s going really well.

Fabbaloo: This machine prints ceramic but could it also do metal?

Hanan Gothait: Yes, and the same printer with metal, ceramics, it can do anything. By the way, regarding changing materials, the machine is not designed simply for putting a cartridge in. We investigated changing materials by the customers. Usually they work with ceramics, so for them changing to metal for them will be kind of radical. But they can do it. We send an engineer and they’ll do the change.

Fabbaloo: The change from one material to another, it takes an engineer to come and do that or the customers can do that?

Hanan Gothait: This is what we say now. Maybe in the future it will be possible. It all depends on the level of purity you want in the material. Because it’s liquid; you need to wash the tubes or change a few pipes. If it’s a general application, maybe it’s OK, but if it’s a medical application, you want to send an engineer from Israel. You want to make sure it’s perfectly fine and qualified and approved. This is why we say an engineer should do it.

Fabbaloo: Is there more than one kind of ceramic?

Hanan Gothait: We currently introduced zirconia. It’s probably the most common high-end ceramic, useful for medical devices, dental, implants, military, automotive, jewelry. So it has a pretty wide usage, high-end. We will introduce additional ceramics next year. Alumina and other widely used ceramics. And metals as well. Later on even titanium.

Fabbaloo: Are there any constraints on the types of metals that you could use? Are there some metals you could not use?

Hanan Gothait: No. Actually for our case it is much easier. If you take lasers, they have some limitations, because some metals are reflective. Some metals oxidize really easily or carbonize. In our case we actually print and then go into the furnace. No specific limitations.

Fabbaloo: Because the heating step is separate separate?

Hanan Gothait: It’s whatever each metal needs. It’s a standard process. This is something developed over 150 years ago. No constraints.

Fabbaloo: If someone were to ask to buy a machine would there be a delay now because you are limiting the number of customers? Do you have a long waiting list?

Hanan Gothait: We are working with all our customers, trying to fit their environments, meet their requirements. This year, probably already fully booked. For next year we are ready to execute. But we still have to open and some customers are willing to wait. Maybe someone wants to go fast, and we can we work with them. But it also depends. Customers that want to go with ceramics, it will be next year more mature. Or metal that will be new. There are many parameters.

Fabbaloo: Once you get through your initial set of clients, and you’ve sorted out your support and all of the customer interaction stuff are you going to be ramping up your production?

Hanan Gothait: Next year is a big ramp up. We are not going for huge numbers, but we are going for “nice” numbers. The year after will probably be much larger.

Fabbaloo: Initially a little bit and then a big expansion. At that point I suspect you’ll have many more materials available materials and therefore many more customers.

Hanan Gothait: Many customers, many mature customers, and many more coming. Everything’s accelerating. We’ll have much wider capabilities and with years, we’ll be able to introduce many more materials and applications. Each application is a big project for us

. This is a specific project in the company, and there is a team dedicated to that. They make sure everything is addressed and all resources are assigned to match the specific requirements.

Fabbaloo: One question we always ask companies is to try and get some hints about the next machine, but in your case, I don’t know that you need the next machine; you need more materials! Wouldn’t your focus be on materials and not so much on the machine at this point?

Hanan Gothait: Absolutely right. We need more materials. And it will happen. But also we are thinking about the next generation of product. This technology is really flexible. Quite easily we can make larger tray. We can add inkjet heads and make it faster. Or reducing inkjet heads and making it low cost. We can bring some variations on materials and have a family of products. It’s easy to do that with inkjet heads. We are thinking: What to do next. We have strong teams with lots of experience; they are really capable.

Via XJET