Researchers have developed a way to create a unique material, metallic glass.

A report on PhysOrg explains new research that has led to a new method of creating bulk metallic glass.

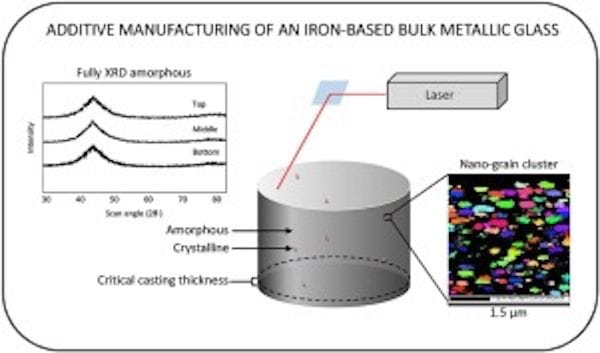

Metal made in the typical manner consists of a microscopic crystalline structure that tightly holds together the molecules, making for a strong metal piece. Metallic glass, sometimes called “amorphous metal”, however is different and does not form in this way and has a disordered atomic-scale structure.

Why metallic glass? These typically alloy materials offer engineering properties somewhat different from standard metals, including:

- Low shrinkage during cooling

- Resistance to plastic deformation

- Better corrosion and wear resistance

- Less brittle than ceramics

- High magnetic susceptibility

- Lower thermal conductivity

- Higher tensile and elastic limits

- Low ductility

- Ability to flow like glass when heated

All of these properties are quite interesting, particularly the last one, as it suggests processes such as injection molding are possible.

Metallic glass has been made previously, but it’s been quite difficult due to the lower thermal conductivity. You see, as a molten mix cools it would normally form crystalline structures and not become glass-like. Thus to make a metallic glass you must cool it extremely rapidly, faster than the rate crystalline structures can form.

In practice this means you can only make metallic glass in small, millimeter-level sizes. After that the cooling slows and regular metal forms.

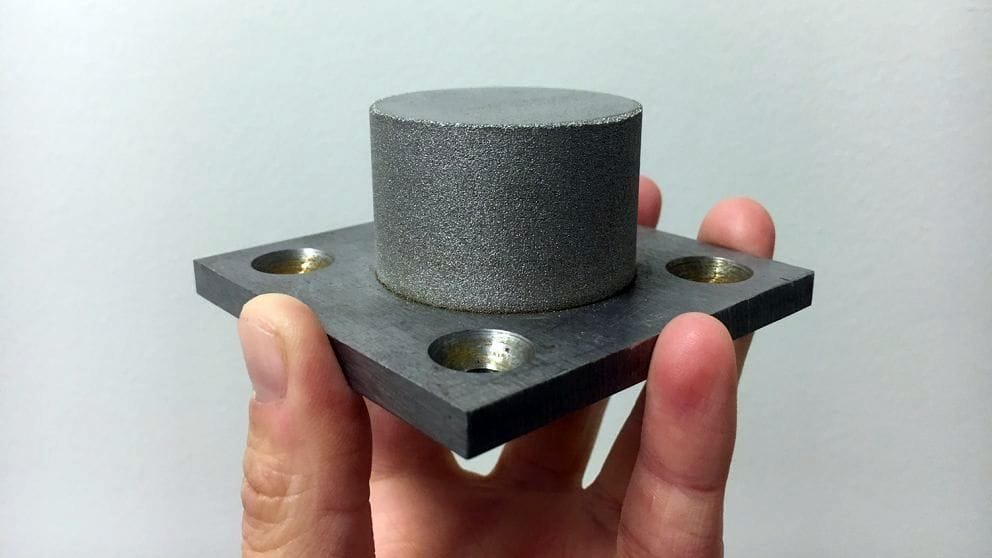

But now the researchers have shown that by tweaking a powder-bed fusion DMLS 3D printing system they can produce metallic glass object in much larger dimensions. This is because the “hot” part of the 3D print is only a single layer, as that is how the DMLS process works. By shifting the laser away the very thin molten layer can cool sufficiently quickly to become metallic glass.

Of course, this requires an appropriate powder mix. Metallic glasses usually require an alloy mix of substances with differently sized molecules. The different sizes make flow difficult and helps avoid the creation of crystalline structures.

In the end this research could, in the future, make available larger quantities of metallic glass for use in new kinds of machines that leverage its unique properties.

And those properties are quite wide, as there are no doubt a near-infinite number of alloy combinations that can be developed and produced using this process.

Via PhysOrg and Science Direct