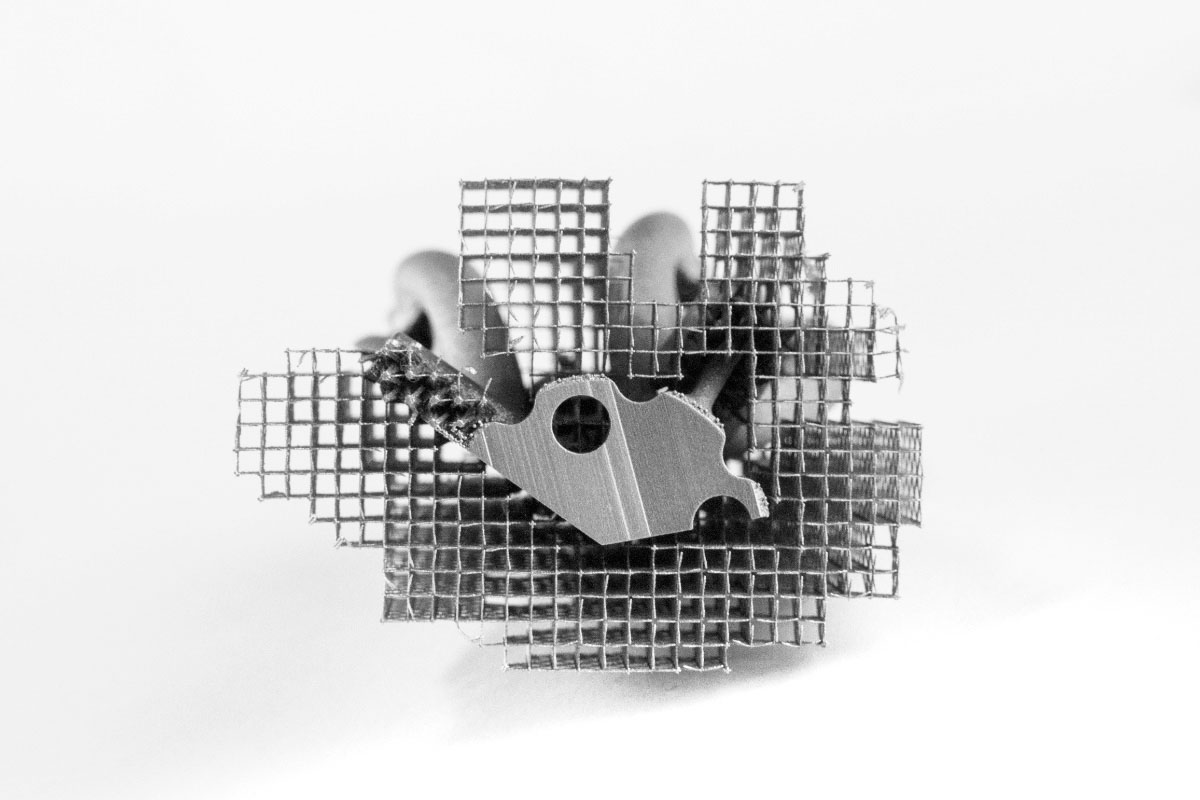

![Stainless Steel part 3D printed with e-Stage support structure [Image: Materialise]](https://fabbaloo.com/wp-content/uploads/2020/05/MaterialiseeStage_img_5eb0a901e919a.jpg)

In part two of my interview with Vice President and General Manager of Software at Materialise Stefaan Motte, we explore recent and upcoming releases geared toward the next stage of 3D printing.

Read part one here.

While stages one and two of 3D printing — making it possible and realizing impactful applications, respectively — provided a strong foundation for the first two decades of Materialise’s industry participation, going forward the third stage sees a focus squarely on productivity. As additive manufacturing moves into production, industry participants are examining what it will take for adoption to see success at scale. Software is a vital part of this process, and Motte’s perspective allows us a glimpse at what’s in store.

“Our software enables users to think of the impossible and make it possible; it is also making it possible for managers to do this in a profitable way. The reality of the 3D printing industry in this moment is that a lot of smaller and mid-sized companies are running their operations near break-even and they need to make this profitable, especially if you look to commodity products. We look at evolutions in our software and features: it’s geared toward exactly that,” Motte told me.

At formnext 2017, the company introduced Materialise e-Stage for Metal, a software solution offering automated support generation that Motte referred to in our recent chat as “a technical marvel” that arose from internal and co-creator analysis of the market.

In analyzing where the costs of production originate, Materialise discovered three primary drivers of cost, which Motte laid out as:

-

Human labor

-

Materials

-

Machine costs

“3D printing is still a pretty labor-intensive industry,” Motte said of the first factor, touching on preparation and post-processing needs. “Materials costs, we see that especially on the metal side, but also on plastic, are still expensive. Additionally, up to 50% of costs are still attributable to machine costs. There are a relatively limited number of builds, so the cost is distributed over not that many parts over the lifespan of a machine. Our R&D program, our innovation program, is really geared at looking at these, to improve the reality for production companies. We are looking to maximize productivity.”

Reduction in the need for human labor, he noted, could have a cost impact in allowing a producer to scale more easily through efficient capacity expansion. That is, he said, “you don’t need to triple your workforce to produce three times more.” Software enables this through such design techniques as nesting, which allows for a fuller use of more of the build volume of a 3D printer, creating the greatest number of parts on one machine. “The more parts, the more productive you are, and this is crucial,” Motte added. Materialise’s automation tools can automate this process, nesting parts for 25% more parts on the same build, accomplished with 40 minutes of software use rather than 8 hours of human labor.

Along with automated solutions, Materialise is looking toward simulation, which last year was announced as a portfolio addition. Motte says this addition is for “exactly the same reason, to maximize productivity of your machine.” An internally optimized workflow scenario saw the team produce the same parts at the same quality with a 42% reduction in timing due to optimization of the build process via simulation.

“A machine is basically almost doubling productivity thanks to simulating. We are looking at the best way of producing a part in the virtual world and applying this to the real world. We will be introducing this to Magics later in the year,” Motte said.

Simulation allows for virtual learning to be applied to real-world circumstances — without using real-world resources. This enables users to make any mistakes virtually, Motte said, noting that a reality of production is that 10-15% of builds require rebuilds following various errors. Simulation allows for prediction of and solutions for errors before using machine time and material on print failures.

“Using simulation, Magics will allow our customers to try various things before they put it on the machine, to see for example what will happen when you orient a part this or that way. Simulate in the virtual world and errors can be predicted in the virtual world; by our estimation and with external testers, estimations say we can cut the failure rate in half by doing so. This can cut labor costs by 90% and reduce failure rates by 50%,” he said.

Because manufacturing is not a high-margin industry, with a typical production setup running at break-even and a minority (“the lucky ones”) running at a 5% profitability rate, Motte noted that translating these simulation figures into actual money can cut costs enough to potentially bring operations toward profitability more easily.

“If we look at actual euro or dollar figures, operating one machine for a year with depreciating costs typically costs around US$400,000 to US$500,000. Using our software, the dollar gains in using automated support generation equates to 10% cost — let’s say US$40,000 less cost in that,” he detailed. “Simulation allows you to reduce failure rate, again costing tens of thousands of dollars, depending on geometries of parts. All in all, using these software tools, you can bring down by 10% or even more the costs on a machine. If you have a production facility running at a 5% margin — and not many are running on a 5% margin — that means doubling profitability or more than doubling profitability. That can move from a loss-making situation to a break-even, or even a profitable, situation.”

Materialise is looking ahead to simulation — and beyond that to integrating artificial intelligence / machine learning.

“We look at all the data from machines from previous iterations. We have all this data coming in, pumping into our backbone and translating it in such a way that artificial intelligence can work with it and improve the situation even further. This will reduce the failure rate, increasing productivity even further. This can basically continue us on this trajectory of making this a mass volume, mass production technology for our users,” Motte said.

Following the announcements at last year’s formnext, I asked whether that was the same timeline we could expect this year — and it turns out I was perhaps overestimating. We’ll see announcements coming in earlier this year, likely in about a month’s time.

“It’s a great journey to be on,” Motte told me as we wrapped up.

“We use our decades of experience, incorporate this into our backbone, incorporate this into what artificial intelligence can use. We work with all our partners, and that is really what this age is about: making this a mainstream, profitable technology used as a normal thing.”

Via Materialise