Researchers at CMU have developed an interesting technique for micro-printing electrodes for batteries.

Battery storage capacity is an issue of increasing interest with the gradual switch to electric devices, and any developments from the 3D printing would be greatly appreciated.

This development deals with the electrode of the battery, which has been 3D printed previously. However, those previous attempts have used an extrusion process that required a rather coarse result.

The problem is that electrical activity happens on a microscopic scale, and the coarse nature of the previous 3D printed electrodes was not optimal. In fact, in spite of using the most appropriate shape possible with this 3D printing technology, the researchers say 30-50% of the total electrode volume is un-utilized.

The new technique should overcome this limitation almost entirely.

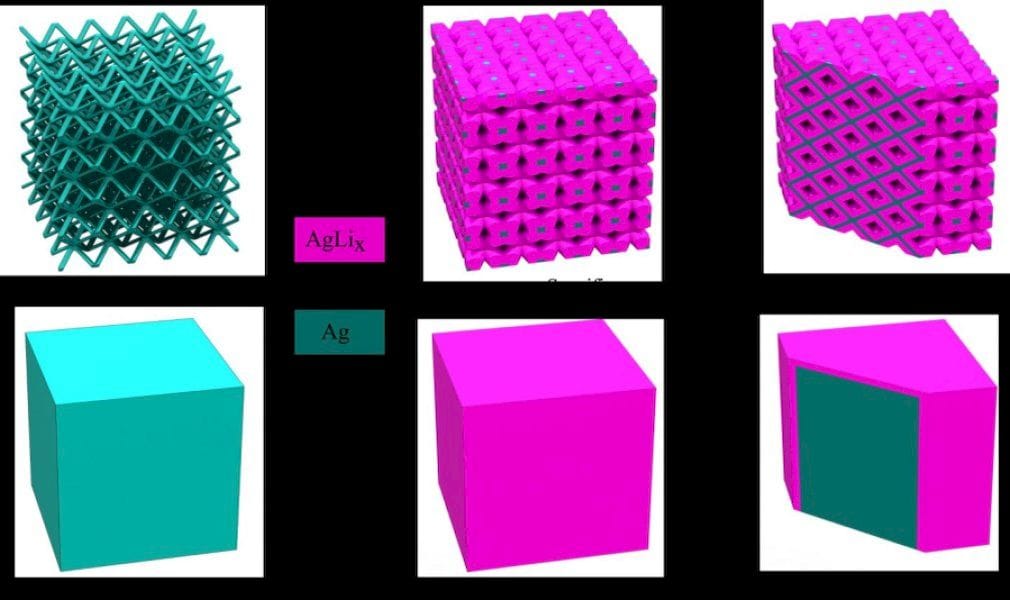

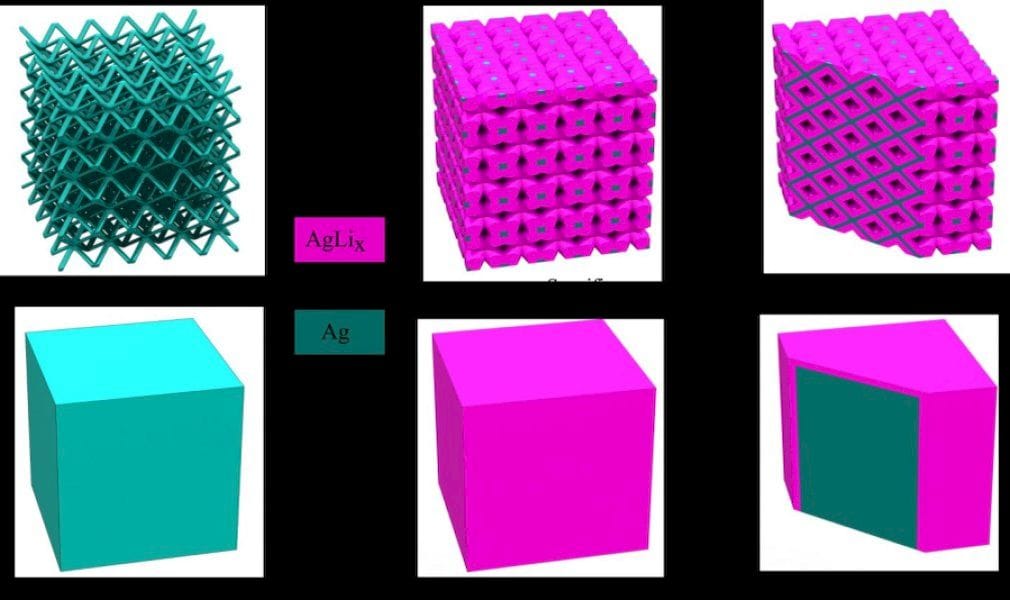

What is the new approach? Apparently they’re leveraging a different 3D printing process, the Aerosol Jet process from Optomec. This process involves atomizing a liquid ink, which is then pushed through a fine nozzle for deposition. The process is typically used to lay down electrical circuits, for example.

But in this case they are using the technique to create unusual 3D structures that are more optimal for electricity transmission. Evidently the new complex structure allows electrolyte to flow around the material, making it far more efficient.

Science Daily explains the benefits:

The microlattice structure (Ag) used as lithium-ion batteries’ electrodes was shown to improve battery performance in several ways such as a fourfold increase in specific capacity and a twofold increase in areal capacity when compared to a solid block (Ag) electrode. Furthermore, the electrodes retained their complex 3D lattice structures after forty electrochemical cycles demonstrating their mechanical robustness. The batteries can thus have high capacity for the same weight or alternately, for the same capacity, a vastly reduced weight — which is an important attribute for transportation applications.

Should this approach be successful, it’s likely it could be used in production for future battery systems.

I’m wondering how much more exploration could be attempted for such micro-scale 3D printing applications. It seems to me that this is an area that has not been particularly well investigated, as there could be countless new applications.

Via Science Daily