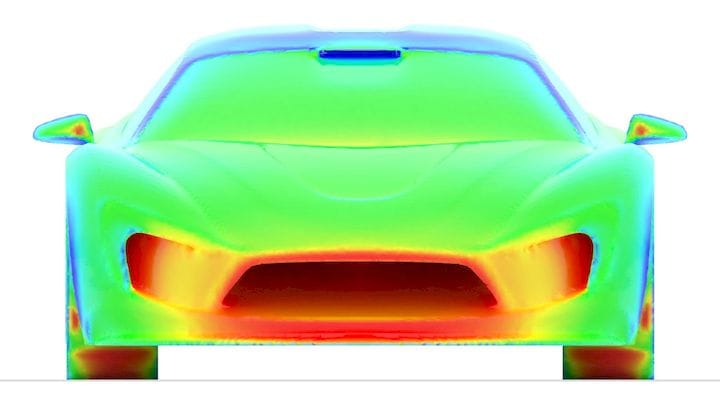

![A surface pressure simulation analysis made by AirShaper [Source: AirShaper]](https://fabbaloo.com/wp-content/uploads/2020/05/airshaper-ov_result_img_5eb0a8e2df280.jpg)

I’m looking at a new 3D service called AirShaper.

It is a virtual wind tunnel with which you can test proposed 3D models, just as if you were putting them into a physical wind tunnel. Except you skip the 3D printing part and do the testing first!

There are some similar simulations available in certain pricey 3D modeling systems, but AirShaper is a standalone service that works independently of your CAD tool. You first develop the 3D model in a CAD tool, then export the design for importation into AirShaper.

Belgium-based AirShaper then accepts your inputs as to wind velocity and direction, after which it can run a full simulation of air flow around your object.

They produce a detailed report that shows quite a few very interesting charts and tables based on the simulation. They produce, for example, charts of drag force and power required by velocity, as shown in this example:

![AirShaper simulation report on force and power [Source: AirShaper]](https://fabbaloo.com/wp-content/uploads/2020/05/airshaper-chart_result_img_5eb0a8e34b2a8.jpg)

Several charts show underpressure zones by degree. Identification of these areas could be a critical factor in the design of certain objects.

![AirShaper's analysis shows underpressure zones on a 3D model [Source: AirShaper]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8e391d94.jpg)

Surface pressure is also examined, as shown here and at top:

![AirShaper 3D view of surface pressure simulation [Source: AirShaper]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8e3e208d.jpg)

A very interesting analysis is the friction report, shown here in a top view. The lines indicate friction and shear forces.

![Friction lines are visible on this simulation from AirShaper [Source: AirShaper]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8e4450dd.jpg)

There’s much more in the report, and we encourage you to take a look at their sample report to see exactly what you get.

But the important thing here is that this tool allows you to optimize your design before you commit to building or 3D printing it. For certain types of designs that would otherwise require multiple design and build iterations, this simulation could save considerable time and money.

That said, there is a cost for using AirShaper. The company offers three levels of analysis detail, with increasing prices at each step. The least expensive and most coarse analysis is priced at €199 (USD$230), and more detailed options are available for €499 (USD$578) and €1499 (USD$1,735). AirShaper says that after the initial fee, subsequent re-runs are discounted by 50%, so using AirShaper is a bit less expensive than you might think.

Via AirShaper