![Using PrintSYSt’s AI system to simplify 3D printing [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a252a2ac0.jpg)

We had a chat with a company that hopes to bring the concept of “one-click printing” to the world.

The company is Israel-based PrintSYSt, founded in 2017. We spoke with CEO Itamar Yona and Co-Founder Eitan Yona to find out more.

The Yona brothers in fact come from a long line of printers. Their grandfather operated a letterpress unit in Israel for many years, and their father worked with offset and early digital 2D printing. Now the sons are working in 3D printing. CEO Itamar is actually a former member of the elite Israeli Intelligence Corps Unit 8200.

The problem they are solving is with a critical part of the 3D printing workflow: how to set the parameters to achieve a successful 3D print. This is often a highly complex matter, as there are literally hundreds of possible parameters that could be set, ranging from temperatures to speeds to flow rates, all of which may need to vary under specific geometric circumstances.

![Itamar and Eitan Yona, the brothers behind PrintSYSt [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a2531f04b.jpg)

Early adopters of 3D printing are well acquainted with this dilemma, including myself: my first 3D print was effectively a shapeless blob, and I spent six weeks of fiddling with parameters to get it to roughly approximate a cube.

But those days are now gone, as many manufacturers provide some standard generic settings for their equipment, and this more or less assures that your print probably succeeds.

But there’s that word, “probably”. That means the generic pre-made parameters approach does not always work. Some 3D models have geometries that simply don’t work with generic parameters and require iteration and experimentation to get them to print correctly.

This is time consuming, frustrating, wasteful, unproductive and generally not fun. For some 3D printer operators, it’s also impossible if they do not sufficiently understand the principles behind 3D printing processes to intuit towards the optimum settings.

But now PrintSYSt has developed an approach that just might overcome this barrier, and it’s quite ingenious.

Essentially they have a very large database of 3D print jobs, including information on the geometry of the part, print parameters and the success or failure of the attempt. Their system leverages this information through sophisticated AI techniques.

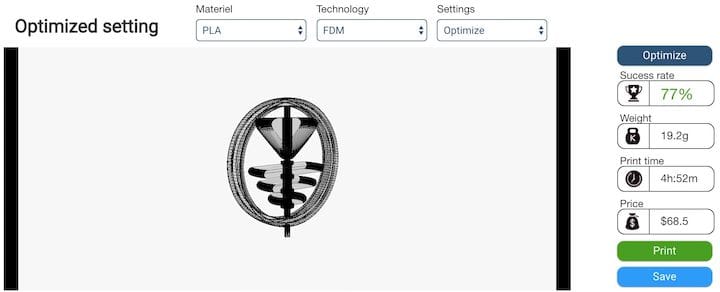

Here’s how it works: you upload a 3D model and they search through the database to find similar geometries and work out the print parameters that would most likely succeed for it, based on previous experience.

Thus they have a sort of one-click experience, at least for the print parameters. You still have to set up your 3D printer and post-process the print, of course. To use PrintSYSt you simply upload the 3D model and answer a couple of simple questions. It then fixes any 3D model problems, slices the 3D model, and provides a GCODE file that you can print.

The PrintSYSt system can recommend a specific 3D printing process. For example, if you had expected to 3D print a particular 3D model using a desktop filament machine, it may suggest that it would be far better to use an SLS machine.

The system can also include constraints on target machines. For example, if your workshop included only certain machine models, it could restrict the results to GCODE for those models only.

I suspect that as the system is used more and more, additional data is gathered that will make the system increasingly accurate at its suggestions.

Their system is also said to be expandable. For example, additional parameters beyond the norm might be included, such as “ambient air temperature”, etc. There are quite a few of these variables that are always at play during printing that are never accounted for.

Today the service is offered to the public at US$290 for 100 prints (business) and US$180 for individuals. For some this might seem expensive, but on the other hand, what is the cost of typically 3-6 failed prints before you get it right? I think PrintSYSt does have a bit of challenge here to explain this benefit to potential clients.

They’re also working with 3D printer manufacturers to integrate PrintSYSt into their equipment directly, so that simplified 3D printing can take place.

3D printing has been a very challenging technology right from the beginning, but hopefully with initiatives like PrintSYSt we may begin to see things become sufficiently simple for many more people to make use of it.

Via PrintSYSt

MakerOS has a brilliant hidden feature in their online service: a sophisticated 3D print pricing calculator that allows operators to determine exactly how to price prints.