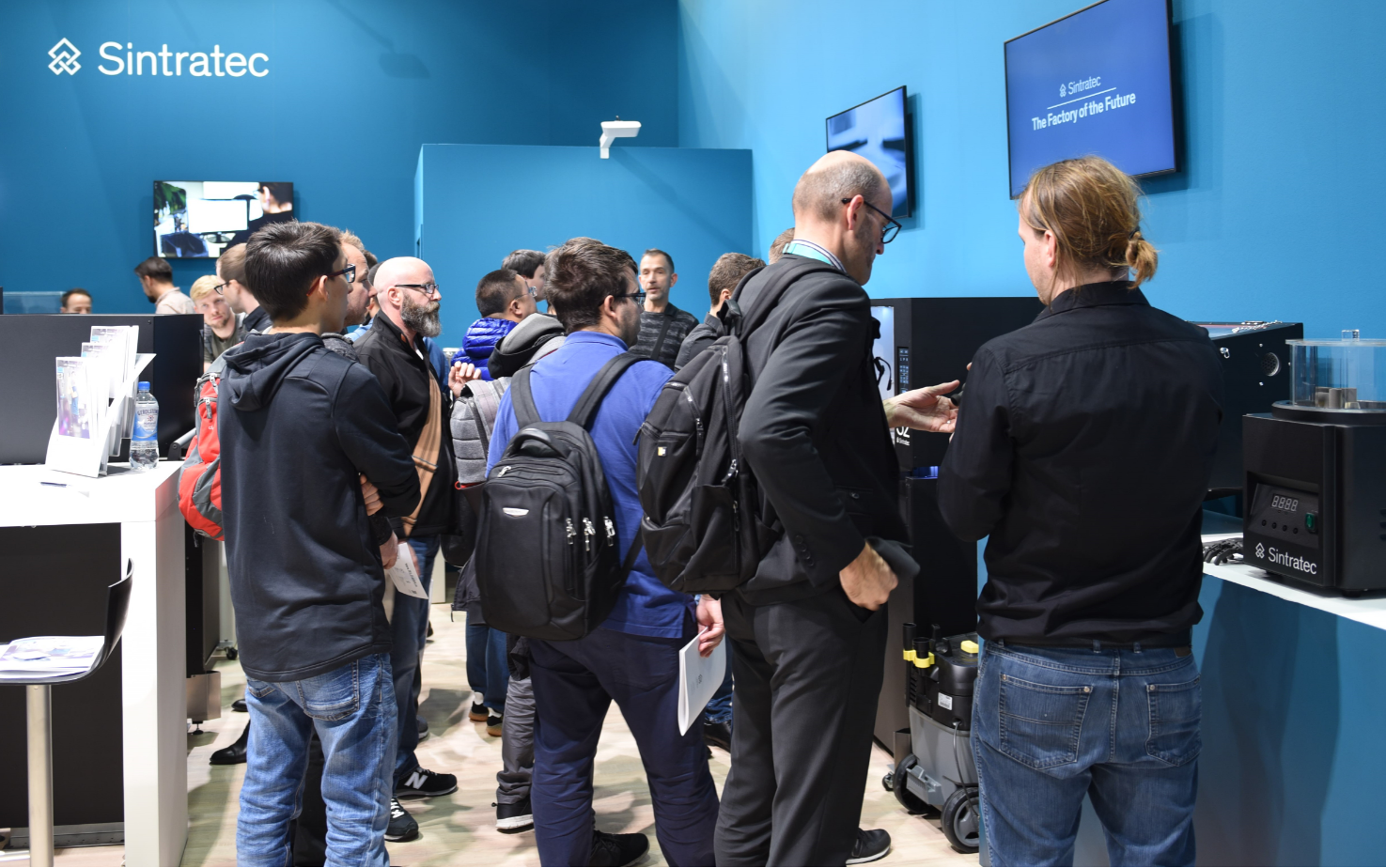

![Sintratec at Formnext 2018 [Image: Sintratec]](https://www.fabbaloo.com/wp-content/uploads/2020/05/222_img_5eafb497593c2.png) Sintratec at Formnext 2018 [Image: Sintratec]

Sintratec at Formnext 2018 [Image: Sintratec]

SPONSORED CONTENT

Sintratec looks back at a successful Formnext 2018.

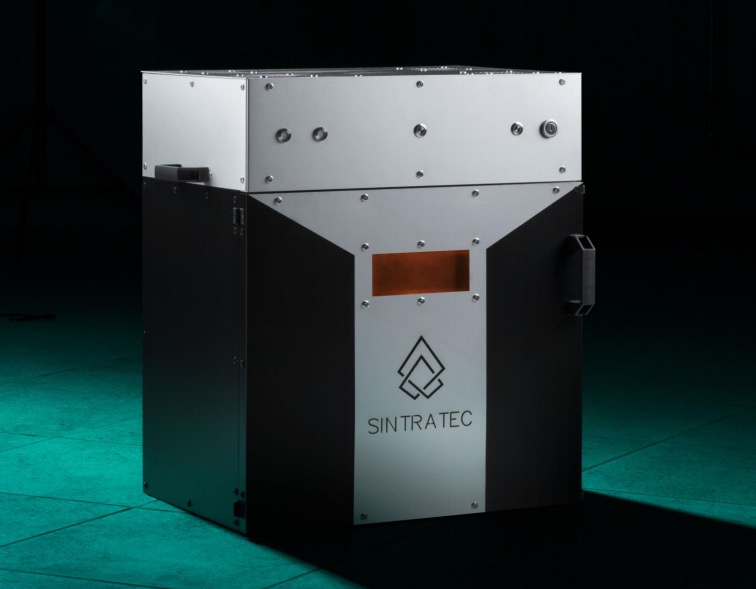

A big bang at Formnext – The new 3D printing system “Sintratec S2” raised a lot of attention among the exhibition visitors. Built for scalability, the modular compact system closes a gap in the additive manufacturing market. Why is there such a demand for the S2?

A scalable system for additive manufacturing with an attractive price-performance ratio? Non-existent in the field of selective laser sintering (SLS), until now. At Formnext 2018 and for the first time ever, Sintratec, the leading Swiss developer and manufacturer of 3D printers for professional use, introduced an innovative, fully integrated SLS system, that excels in many ways.

The main advantages at a glance

The Sintratec S2 solution stands out by its closed-loop workflow. Users benefit from a complete 3D printing system covering the entire processes from printing to post-processing. The system allows printing almost without interruption. Inserting ready Sintratec Material Units for the next print job takes only a few seconds. Furthermore, a semi-automatic de-powdering system and two additional modules for post-processing (a sand blasting module and a polishing module) ensure fast finishing work. With this, tedious cleaning processes are a thing from the past.

The Sintratec S2 is scalable according to the user’s needs. Additional modules can easily be integrated. In doing so the solution allows running a wide variety of materials on in a production line at the same time. These advantages are based on the main principle of the brand-new system, which is thoroughly new in the SLS field: Users can not only print prototypes but also small series. Last but not least, in its basic configuration the Sintratec S2 is available for an unusually affordable price.

Interested crowd from all over the world

The demand at the Sintratec booth at Formnext was high. Customers running a predecessor system (Sintratec Kit or Sintratec S1) as well as a large number of other interested professionals informed themselves about the functions of the new end-to-end solution.

Dominik Solenicki, CEO at Sintratec AG, summarizes: “We were overwhelmed by the activity at our booth. We had over 300 in-depth discussions per day and a surprisingly high amount of reservations for the Sintratec S2 were made right on the spot. We are now more than ever excited to bring the S2 solution to market and power new applications all over the world.”

![[Image: Sintratec]](https://www.fabbaloo.com/wp-content/uploads/2020/05/555_img_5eafb49b22d48.png) [Image: Sintratec]

[Image: Sintratec]

Technically clever

From the technological perspective, the Swiss engineers have equipped the Sintratec S2 with some clever features. For example the cylindrical printing area and the ring lamps guarantee a better heat distribution during the printing process. Thanks to a 4K camera the printing process can also be monitored in detail. Especially ergonomics were considered: The Material Handling Stations allows a comfortable and efficient unpacking of prints and recycling of printing materials. Easy to access, this module was constructed to be operated at the user’s arm level.

What’s more, the intelligent powder recycling concept also increases economic efficiency. With the Sintratec S2, the Swiss machine manufacturer serves a fully integrated end-to-end solution to the community of additive Manufacturing with a promising future!

Reservations recommended

Sintratec users benefit from a rapidly growing global network of resellers and service partners. In order to reduce waiting times for the S2 system, the Swiss technology company recommends prospect customers to place system reservations.

Via Sintratec