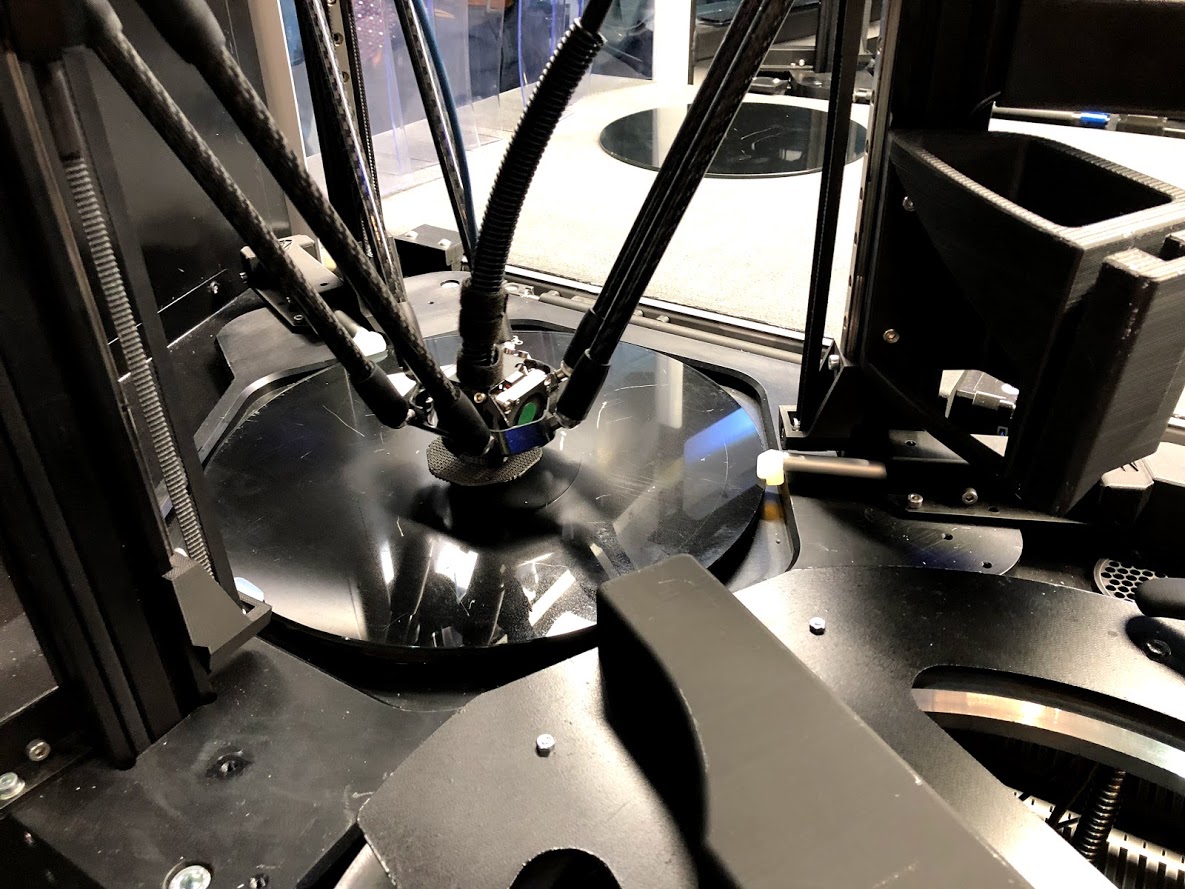

![AMCELL running at formnext 2018 [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/IMG_20181115_151628_img_5eb09fdd813a2.jpg)

Automation is coming to 3D printing, and a new system is designed with productivity in mind.

Spain-based TRIDITIVE has created AMCELL, a “fully automatic 3D printing machine capable of both polymer and metal materials” that is “as automated as possible to create a farm with high productivity,” CEO Mariel Díaz Castro explained when we spoke next to the running system.

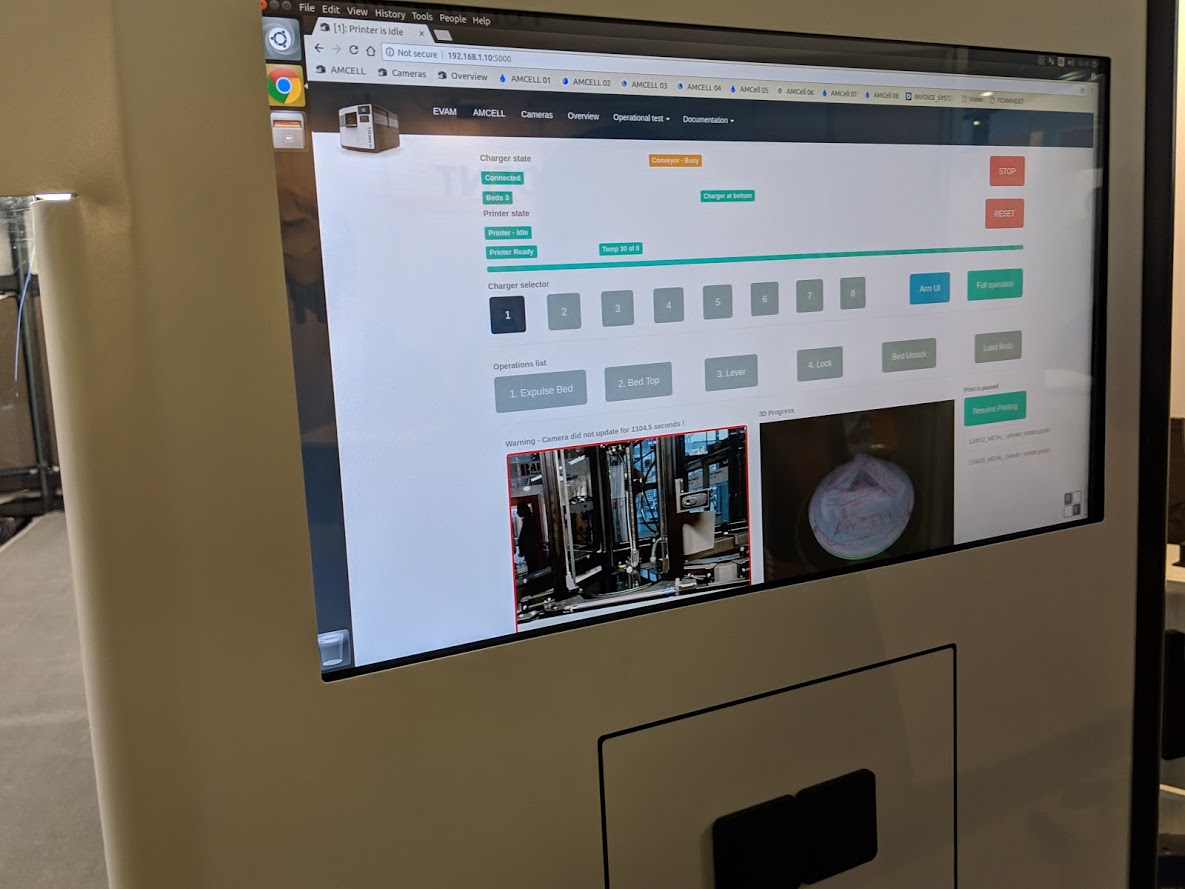

The Additive Manufacturing Cell (aha, “AMCELL) is a large machine including several delta-style extrusion-based 3D printers. The company explains that AMCELL is powered by its EVAM software, which “allows managing manufacturing queues taking into account urgent orders, minimizing machine downtime and remotely monitoring the production process.”

Automation is a major benefit in scaling up additive manufacturing processes, and incorporating a 3D printer farm into an integrated system allows for a smoother end-to-end experience.

![Mariel Díaz Castro [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/IMG_20181115_151605_img_5eb09fde174d9.jpg)

Up to 10,000 parts can be 3D printed each month, Díaz Castro noted: this is “mass production for real.”

“We are based in northern Spain, where there are a lot of heavy metal industry participants looking for high-volume manufacturing at a low cost,” she continued. “This is our idea for reducing this cost.”

When a print job is done on each 3D printer, the plate with the completed build lifts off the print bed onto a conveyor belt, and a robotic arm places a new plate ready for the next build. The easy-to-use interface allows for manual intervention in which an operator can select any robotic arm to focus on a printer, or EVAM can manage everything, allowing for highest levels of automation.

“The machine manages the operator, not the operator managing the machine,” Díaz Castro said of the depth of automation.

The system continuously monitors material levels and plate supply.

“We don’t need the highest skilled operator with the machine, so it is ready to introduce to the market today. You can have engineering in one country and the factory in another. It can be a delocalization of factory,” she said.

Because the skills gap in advanced manufacturing technologies is a major issue at present, the allowance for operators to be easily trained enables a smoother potential adoption.

AMCELL can be configured to meet needs; while the system I saw featured eight 3D printers, fewer can be installed. Each printer has a build area with 220mm diameter and 330mm height and can go up to 180C.

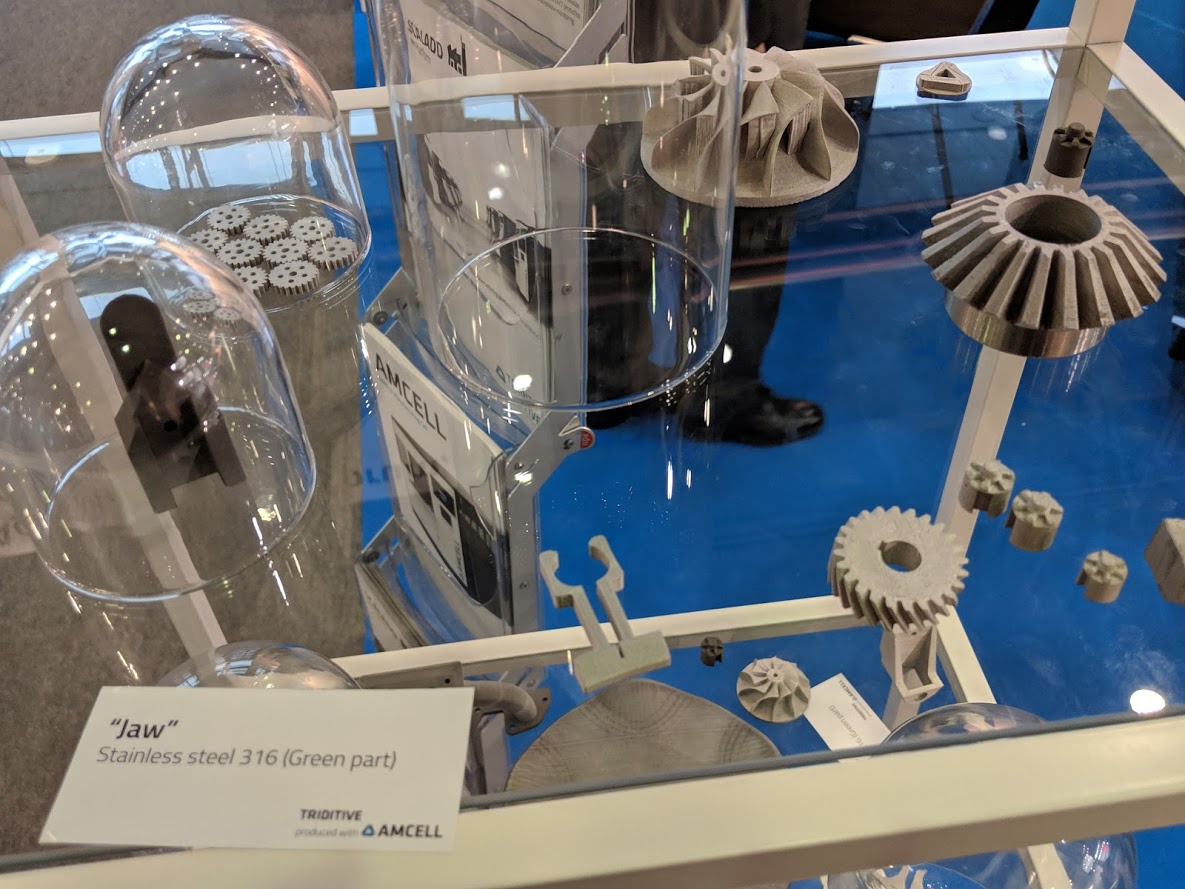

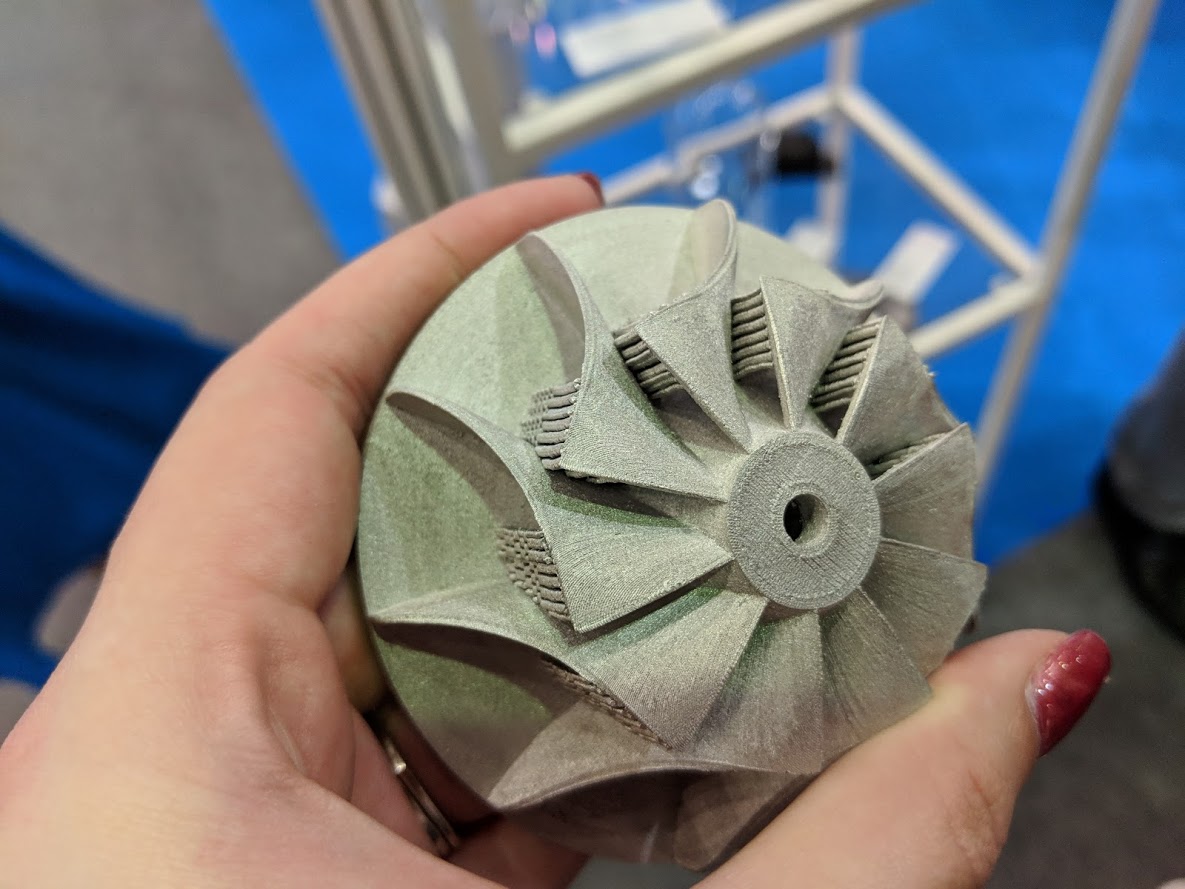

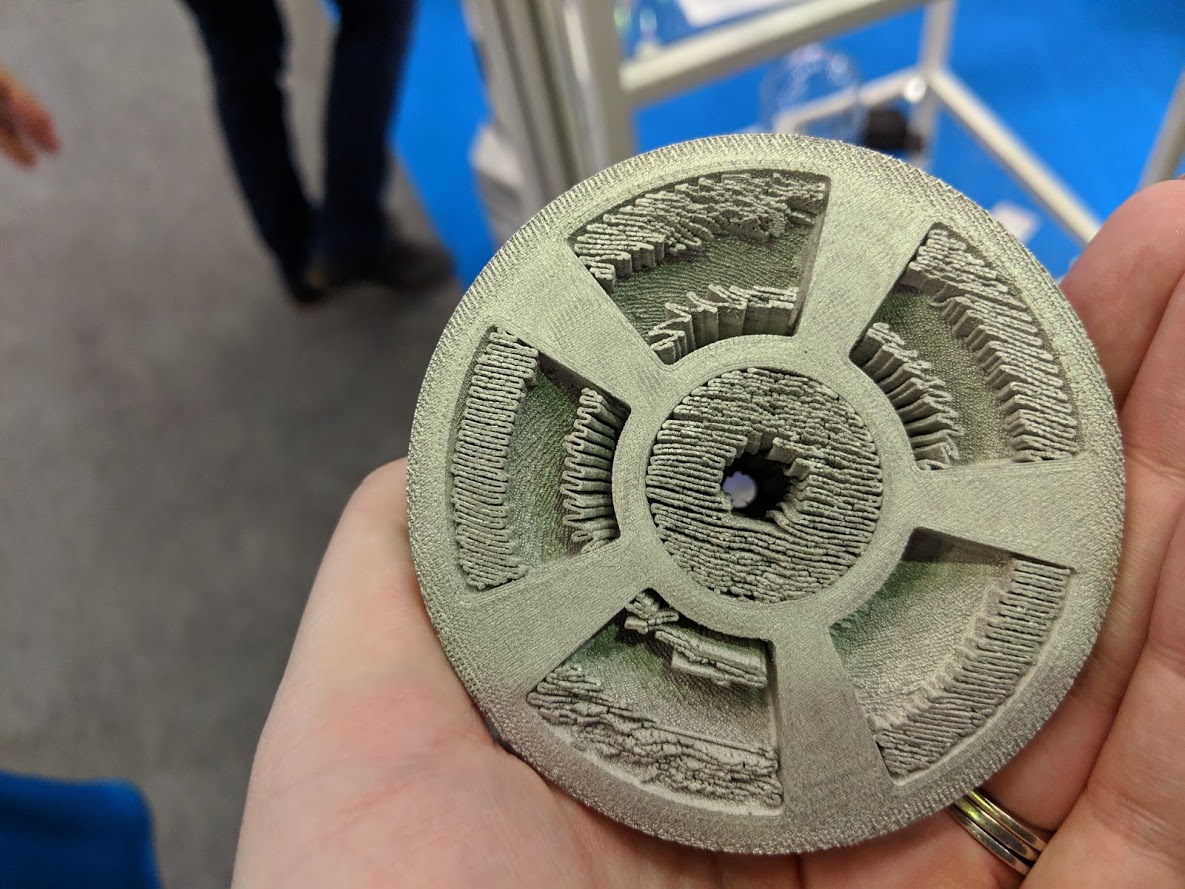

The system is compatible with both polymer and metallic filament types. TRIDITIVE notes that it currently works with:

-

316 stainless steel

-

Polymers: PLA, ASA, ABS, HIPS, Polyamide 12

-

Polyamide reinforced with carbon fiber

The stainless steel is an Ultrafuse material. Díaz Castro noted that the team is “looking forward to having more materials in the near future.”

For polymers, she continued, the company is working with Filamentum and focusing on “working with tech polymers; it’s what customers want for mass manufacturing of final parts.

“We have been working on this for years,” Díaz Castro said of the inception of AMCELL.

“I studied engineering, did a startup, and then came up with the idea of automization for printers for a lot of parts. We want to grow, and are looking for funding.”

TRIDITIVE was printing live as we spoke, with the AMCELL system hard at work with several printers while others served to show how additional build plates could be added quickly and easily.

Reservations for AMCELL systems are open; shipments are targeted for Q2 of 2019.

Via TRIDITIVE

A blog post reveals much of what happens behind the scenes at 3D print service Shapeways.