![All smiles for the J720 [Image: Stratasys]](https://fabbaloo.com/wp-content/uploads/2020/05/j720_img_5eb09c22a1ab4.jpg)

It’s not Stratasys’ first dental-targeted 3D printer, but it is its most advanced.

The J720 debuted last week at the ever-important LMT Lab Day. The event is often home to interesting announcements in dental 3D printing, and this year’s edition was no exception.

We see a lot of solutions in dental 3D printing arising, and there are many reasons for that. Dentistry is a market where one size fits none; every solution has to be patient-specific because every mouth is different. As additive technologies continue to advance, more is coming straight to the dental lab.

In 2016, Stratasys unveiled its highly advanced full-color multi-material J750. That 3D printer is capable of remarkable detail and leads to legitimate reactions of “this was 3D printed?” Stratasys is keeping it in this multi-material family with the new dental introduction, adding to the company’s existing portfolio of options for dentistry.

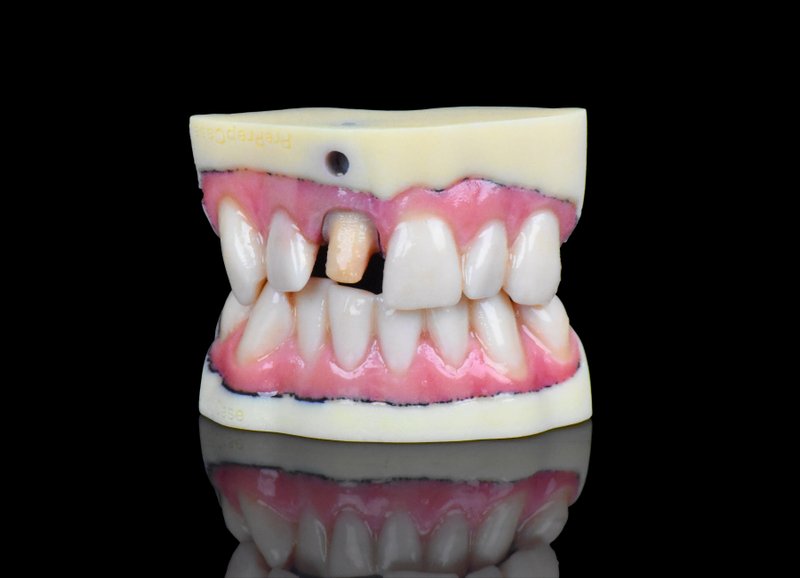

There are two interesting aspects at play with the J720: color and speed.

Stratasys says of these:

“Backed by more than 500,000 color combinations, the multi-material 3D printer produces extremely high resolution, patient-specific models with precise accuracy – at 1.75x the daily throughput of high-end DLP and SLA dental 3D printers.”

![The J720 dental 3D printer [Image: Stratasys]](https://fabbaloo.com/wp-content/uploads/2020/05/Render_StratasysJ720_LeftView_0219a_img_5eb09c231a547.jpg)

The company notes the machine’s large build tray as a particular enabler for busy dental labs, capable of working on several patient models in a single build.

Specs include:

-

Build volume: 490 x 390 x 200 mm

-

Layer thickness: Horizontal build layers down to 14 microns

-

Accuracy: Up to 200 microns for full model size (for rigid materials only, depending on geometry, build parameters and model orientation)

That build volume can see more work done more quickly — and reduce the manual intervention needed for smaller 3D printers to swap out between print jobs. Automation is key for digital dentistry solutions, so any hands-off productivity is a plus.

The color comes into play for more realism. Patients don’t always know what they’re seeing when they look at dental models; I know mine have always been simple plaster casts made from those terrible bite trays. Looking at a more realistic treatment model before beginning work can help to increase patient acceptance of case presentations, Stratasys proposes.

“Labs today operate in a very competitive space where differentiation counts on mastering the digital workflow and expanding into new products and services,” said Barry Diener, Dental Segment Sales Leader, Stratasys.

The J720 operates with GrabCAD Print software. Compatible materials include those in the VeroDent and other Vero families; Tango and Agilus 30 flexible families; and both soluble and water jet removable supports.

Availability is slated for Mary 2019; pricing has not yet been announced.

Via Stratasys

Formlabs has struck a deal with a dental resin provider that could stealthily grow their business significantly.