![[Image: Dyndrite]](https://fabbaloo.com/wp-content/uploads/2020/05/DyndriteMonitorMockup_img_5eb09a233dc9d.jpg)

A new player in the field is going to be a very big deal for additive manufacturing.

A lot of new companies say they’ve developed a game-changing world first, and those ambitions are good for any entity hoping to make actual impact. Sometimes the industry gets lucky and there’s something behind the marketing speak.

After about 3.5 years in stealth, Seattle-based Dyndrite emerges today.

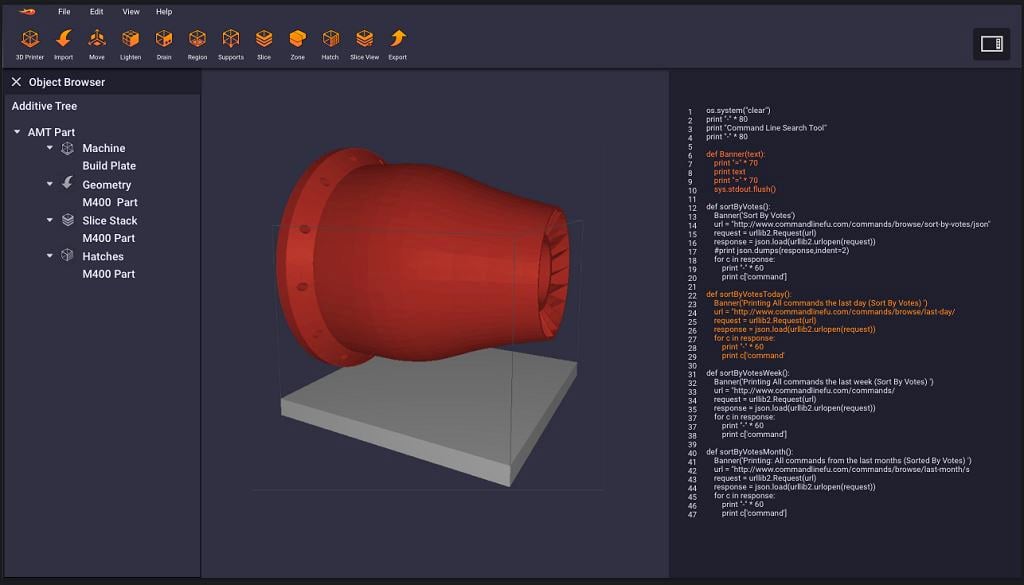

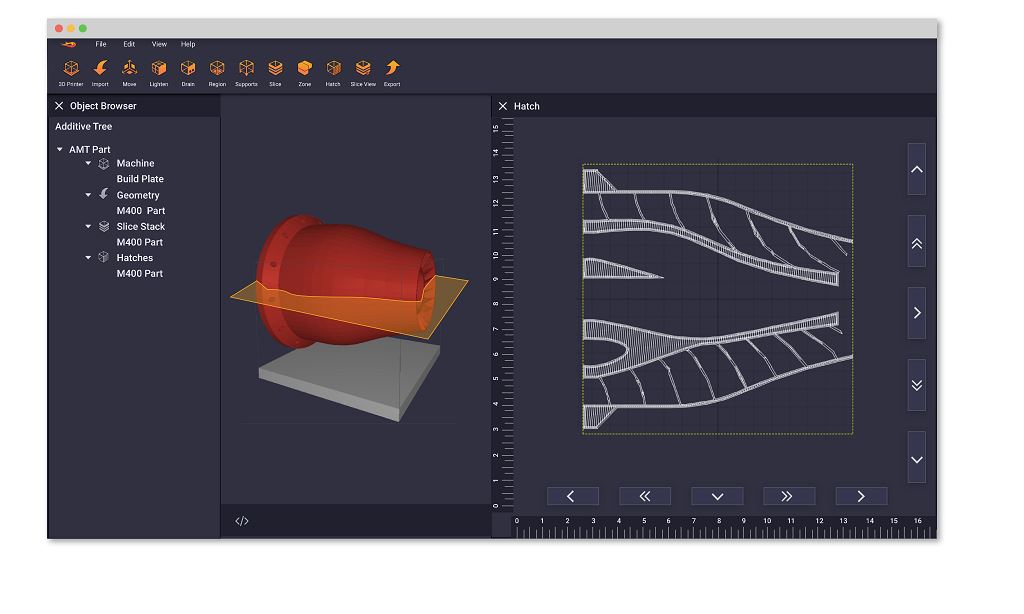

The software company is promising a new approach to software with the Dyndrite Accelerated Geometry Kernel (AGK), which they call the “world’s first fully GPU-native geometry kernel.” They are also introducing the Dyndrite Additive Toolkit built on that kernel.

I spoke with Dyndrite CEO Harshil Goel and Chief Marketing Officer and Head of Developer Relations Shawn Hopwood for a demo and some insight.

It wasn’t long into our chat that I realized there’s something significant happening here: we’ll have a lot more coming soon about Dyndrite. So as their name comes up more, good to note that it’s “Den-drite,” not “Dine-drite.”

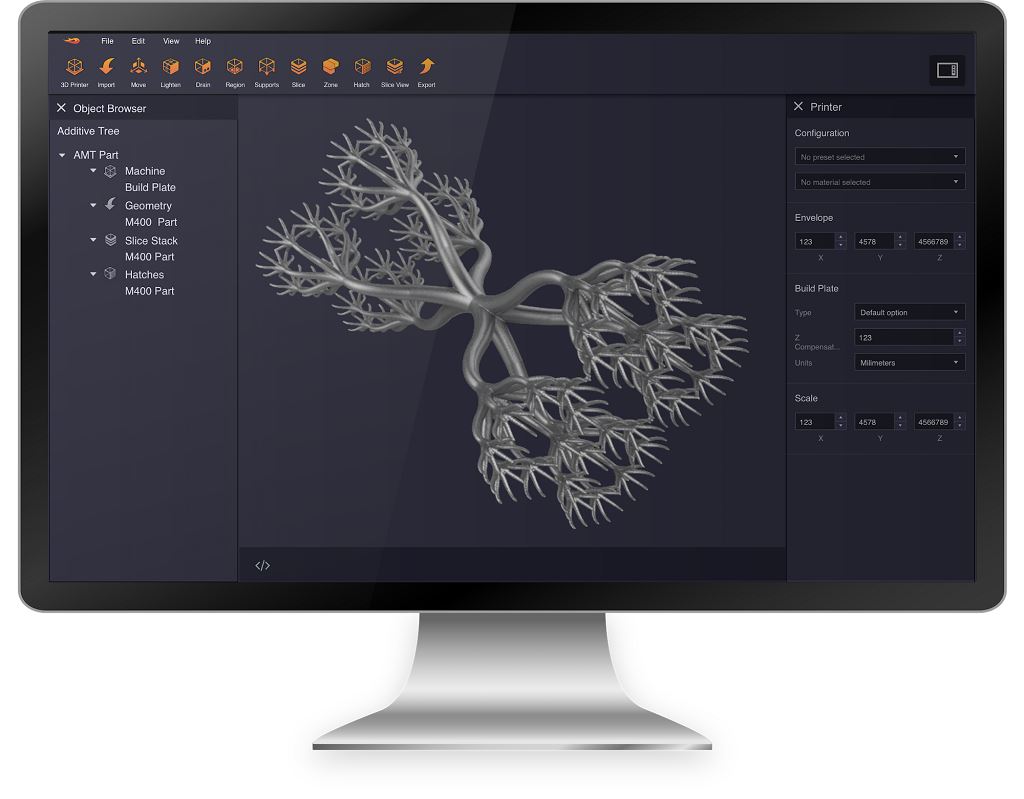

As Goel walked through the demo — which he was running on a pretty basic business laptop — he also had another demo running simultaneously. That demo was set to generate a lattice using a very well-known software suite familiar to pretty much anyone working in additive manufacturing today. As he set that one to run, he then turned to Dyndrite’s offering to generate its own lattice, saying boldly, “Let’s do something no one else can do and make it 5x finer.”

The lattice came up quickly, set to fit the resolution of any DMLS machine on the market today, then sizing and resizing it, all while the other software was working on a first design.

Dyndrite is set out to offer next-generation efficiency in additive manufacturing, Goel said: “The key word is efficiency.”

The company has just finished a substantial Series A funding round to the tune of more than $10 million. Google’s AI-focused investment fund Gradient Ventures leads the round, participating with Cota Capital and existing investors Amplify Ventures and The House Fund as well as private investor and former Autodesk CEO Carl Bass. The funding is set to see Dyndrite grow, with a goal of 30 employees by year-end; they currently have just over half that number in place.

The goal, Goel continued, is to “gain control over the CAD to additive workflow.”

“The industry is currently in a chokehold with STL. There are all kinds of issues and Band-Aids needed, where you have to corral ideas to fit into the workflow. We had this idea of, if an engineer spends so much time designing something beautiful, why is the first thing we do destroy it changing file types to mesh it and slice it and ready it to print? The key is that it needs to be fast, it needs to be sophisticated, users need to rapidly iterate. No engineer is going to design something just once, they’re going to design it three or four times. When I talk about slicing, I don’t mean slicing the mesh, which is what every other software does, but slice the native geometry, what controls the quality of the print,” Goel continued. “Wouldn’t it be lovely if the same piece of software could automatically optimize and set laser speeds and prints?”

The key to all that Dyndrite is doing is this geometry kernel.

Goel and Hopwood liken the kernel to what happened in the 1980s for 2D printing.

“We’re essentially replicating what happened with Adobe and PostScript from the desktop printing revolution. One of the biggest drivers was the PostScript format. We should hopefully be viewed in the same light, in that STL is dot matrix and we’re hoping to move toward something lean and mean, removing all those bottlenecks,” Goel told me.

The team recognized that existing kernels upon which other systems and software were built were written in the 1980s, “so they were for legacy design needs,” Goel said. With new processes come new design needs (hence the frequent focus in this and other publications on design for additive manufacturing, or DfAM). So Dyndrite developed a kernel, “consumed our own dog food, and wrapped it up in Python API.”

Hopwood continued, “The fact is that manufacturing hardware has outpaced the software. The software industry has been behind while hardware has been growing by leaps and bounds. We’re turning that on its head, providing capabilities that printers can’t keep up with. We expect to see an additional revolution in what printers can do based on what we provide.”

That’s a big, bold claim in an industry already playing a major role in the current Industrial Revolution / Industry 4.0. But this is, after all, an industry built on bold claims and bold moves.

We’ll have more to come soon on Dyndrite’s kernel as well as launch partners for its Dyndrite Developer Program and Council. If the familiar names of the Series A investors weren’t enough, the Developer Program includes more well-known names in 3D printing:

-

Aconity3D

-

EOS

-

HP

-

NVIDIA

-

Plural Additive Manufacturing

-

Renishaw

A high level look at the new kernel:

-

Hybrid kernel

-

Turbocharged math engine capable of splicing splines and complex geometries

-

-

GPU acceleration

-

Iterations go from minutes to seconds

-

-

Python API interface

-

High level of accessibility simplifies complex workflow

-

As a quick note on the second point going back to the lattice generation where we began, during the half hour we spoke, Goel showed several versions of several designs beyond the initial lattices. The other, well-known software never finished a first version of a lattice.

Select developers and OEMs are now working with the Dyndrite Kernel, with broader availability slated for this summer. The Dyndrite Additive Toolkit is now in limited release, with a public beta set for this summer.

There are many more details following Dyndrite’s unveiling, including IP protection, scalability, speed, workflow, and strategy — but today, the overarching message is one of introduction.

Meet Dyndrite: you may just get to know them very well now that they’re out of stealth.

Via Dyndrite

MiniFactory’s new software produces a very useful report for each 3D print that may be important for clients. We had a close look at one.