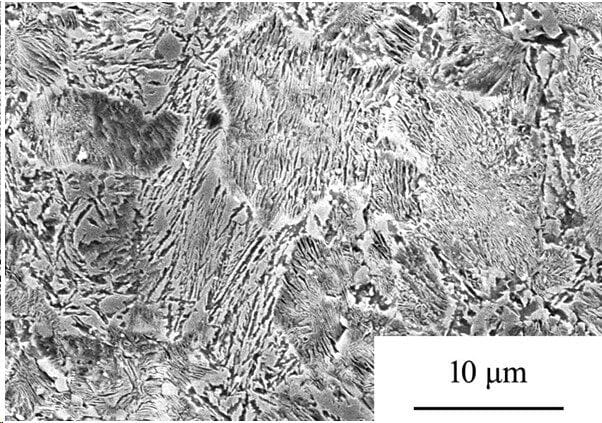

![Microscopic view of bainite, a steel alloy [Source: SUSU]](https://fabbaloo.com/wp-content/uploads/2020/05/bainite_result_img_5eb09b446c4c4.jpg)

Metal 3D printing has come a vast distance since it was first introduced some years ago.

Today we see constant innovation in the space. We see metal 3D printer manufacturers increasing the size of their machines, increasing the quality of their prints, and adding convenience features and integrating directly into factory workflows. It’s a neverending stream of innovation.

Seeing that, one would think that metal 3D printing is approaching the “end”, where it somehow meets the current state of affairs in traditional metal manufacturing. I have a suspicion that this will actually never happen.

Given the tremendous progress of metal 3D printing over the past decade, it’s easy to lose sight of happenings in the traditional manufacturing world. The truth is that traditional metal manufacturing has not stayed still; it’s also improving.

I recently read a piece on Phys.Org describing some research taking place at South Ural State University to develop a new form of steel. Steel is a crafty combination of iron and carbon to produce a very useful and strong material at relatively low cost. It’s been around for at least 4000 years, and because of that we may think it’s old news. But it’s not.

The researchers were focusing on a new alloy of steel called “bainite”. It’s quite similar to martensite, a super-hard alloy of steel produced through an unusual cooling process. However when you mix in trace amounts of nickel, chrome, manganese, and silicon you can produce bainite. Theoretically this material would have additional malleability, but be just as hard as martensite.

One thought that came to mind when I read this was simply this: “could this material be made into powder form and could it be used in 3D printing?” I have no idea when that could be, or whether 3D printing bainite would be feasible.

Whether the researchers succeed in developing this material is not the point of this post. What I’m trying to say is that metal 3D printing is always going to be playing catch-up with general metal manufacturing.

There will always be new materials for 3D printing to adopt. There will never be an end, and materials will always get better.

Via Phys.Org

No one seems to offer collaborative 3D printing modes on dual extrusion devices. We explain why this is the case.