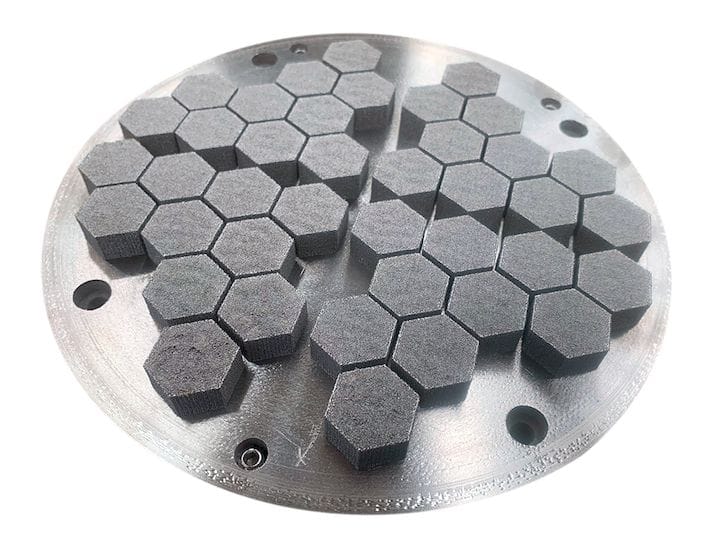

![A relatively complex titanium 3D print made with the MCP process [Source: Aurora Labs]](https://fabbaloo.com/wp-content/uploads/2020/05/Fasthexagons_result_img_5eb099ea98d23.jpg)

Australia-based Aurora Labs has performed a complex test of their new parallel metal 3D printing process.

They first announced the secretive process back in November at formnext 2018, where we were able to speak to the company’s representatives directly about the project. It’s a fascinating process that essentially parallelizes the traditional powder bed / laser approach used by so many other metal 3D printer manufacturers.

The secret sauce in this process is a grating through which layers of powder material are cascaded successively, and through which lasers fuse selected areas. The company believes this approach will enable them to meet their long-term goal of producing a metal 3D printer capable of printing 1000kg objects in less than 24 hours.

![The MCP process involves firing sintering laser through a grating [Source: Aurora Labs]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb099eac4684.jpg)

While their first tests were attempting to 3D print straightforward basic objects, a question remained as to whether their process, called Multilevel Concurrent Printing, or MCP, would be able to handle fine details and more complex geometries.

The most recent test attempted to address those concerns by 3D printing a 10mm tall titanium object with a lot more detailed features. As you can see in the image, they seem to have succeeded.

Even better, this print, which appears to be 20cm across, was apparently completed in only 20 minutes of print time. That’s an astoundingly fast metal 3D printing operation. A video of the operation shows that the MCP “grating” needed only two passes to complete the entire object, as each opening in the grating corresponded to a new metal layer.

![Aurora Labs has 3D printed complex aluminum parts using their new MCP process [Source: Aurora Labs]](https://fabbaloo.com/wp-content/uploads/2020/05/aurora-labs-aluminum_result_img_5eb099eaebeed.jpg)

Another test involved high-density aluminum, where another complex part was produced using MCP. Aurora Labs says the aluminum part had a density of 99%, suggesting the MCP grate approach does not introduce air gaps when distributing powder over the print bed.

We’ve been following Aurora Labs for several years now, and they have been following a success trajectory on this project quite closely. Based on the results of this test and their previous work, it seems they should be able to meet their now-not-so-ridiculous goal of building a 3D printer capable of producing 1000kg prints in less than a day.

Via Aurora Labs

Aurora Labs announced an important milestone in the development of their rapid metal 3D printing process.