![[Image: NIAR]](https://fabbaloo.com/wp-content/uploads/2020/05/niaram_img_5eb093a2a4fb5.jpg)

America Makes has announced its third Satellite Center.

The organization’s mission is both simple and ridiculously complex: accelerate additive manufacturing in the United States. It’s straightforward, and elegant for being so; but when it comes to the practicalities of fulfilling the vision, complexities arise.

How do you “accelerate” something that’s already happening? Additive manufacturing is a rising force in industry, and the US is among the countries leading that charge. When America Makes was founded, it was with the understanding that that adoption needs government support, as seen in the most successful Industry 4.0 leaders around the world.

America Makes Satellite Centers

The accelerator itself is based in Youngstown, Ohio.

The city was a giant in the heyday of the steel industry, and maintains a significant legacy in traditional manufacturing. Downturns have seen a significant change in the city, though, and it’s not what it was — but much like many of the cities hardest hit in the US’ formerly thriving Steel Belt, it’s rising from those ashes as part of the Tech Belt.

Youngstown is only about 90 minutes’ drive from my home base outside of Cleveland, and I’ve appreciated a few opportunities to visit America Makes to speak with the team and see the growing additive manufacturing installations housed there. That convenience factor isn’t there for everyone, though, and for a nationally-focused program, America Makes has needed to broaden its concrete reach.

In 2015, the program announced its Satellite Center (SC) model, which debuted with The University of Texas at El Paso (UTEP) housing the first SC at its W.M. Keck Center. This year, the AM-SC program expanded in March with a second SC established at the Texas A&M Engineering Experiment Station (TEES) in College Station, a part of The Texas A&M University System.

America Makes explains of its Satellite Center program:

“The objective of a America Makes Satellite Center (AM-SC) is to extend the reach of the existing America Makes mission – to complement and expand America Makes’ current regional, industrial, and technological footprint.

The AM-SC engages with local companies and educational institutions to supply education and training in additive manufacturing technologies, and focuses on the transition of additive technology from the research lab to commercialization.”

Now it has expanded again mere months later, with the third AM-SC.

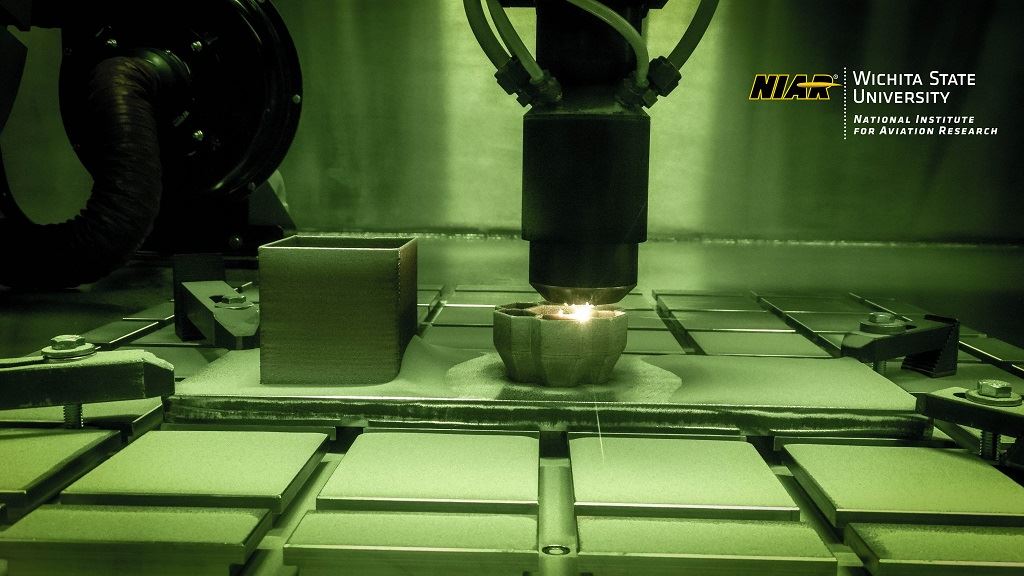

NIAR

The National Institute for Aviation Research (NIAR) is located on the campus of Wichita State University (WSU) in Kansas.

Youngstown, El Paso, College Station, and Wichita: America Makes’ official locations are all rooted in areas with significance to US manufacturing.

While, again, Kansas may not seem the obvious choice for a major government program focused on advanced manufacturing, it makes a great deal of sense. Wichita has a deep legacy in aerospace, and NIAR in particular is remarkably advanced with new capabilities in the heart of an aviation mecca.

Again a place I have had the good fortune to visit in the past — a few years ago, Dassault Systèmes opened a 3DEXPERIENCE Center at NIAR — the facility is large and growing. Students and professionals work side by side with many of the latest technologies.

In addition to additive manufacturing, NIAR houses labs dedicated to work in CAD/CAM, advanced coatings and materials, mechanical testing, nondestructive testing, reverse engineering, robotics and automation, VR, a wind tunnel, and more.

Like the two AM-SC locations to precede it, NIAR is a platinum member of America Makes, and thus very familiar with the objectives and aims of the institute.

AM in Aerospace

NIAR as an AM-SC is bringing something else to the table: application-specific focus.

“As our next America Makes Satellite Center, NIAR will have the unique distinction of being our first industry-specific Satellite Center solely focused on advancing the use of additive manufacturing within the aerospace industry. We are excited for this enhanced collaborative partnership with NIAR to get underway,” said America Makes Executive Director John Wilczynski.

Aerospace is, of course, one of the major application areas today for additive manufacturing. Lightweighting, design complexity, and low-volume/high-margin parts creation are among the key benefits to these technologies that strike a chord with high-flying usage.

Wichita styles itself the “Air Capital of the World,” and adding capabilities in advanced manufacturing are set to further cement that moniker. This extends to both civilian and defense aviation.

“If we want to stay cutting-edge, we want to make sure that we make the lightest, strongest, most efficient aircraft in the world. And if it leans to be additive, then we want to be able to make it here in Wichita, and we want to have the supply base here to make additive parts,” said John Tomblin, WSU Vice President for Research and Technology Transfer.

“We have about 100-plus machine shops that exist in the county. Lots of machines work here. If you think about utilizing that supply chain and keeping it current with what the future is doing … we want to be prepared. We’re the No. 1 manufacturing community in the United States. … If we see the industry start to shift to additive, we want to make sure that our suppliers and our people here in our region can do additive as well. We want to maintain the No. 1 ranking, we still want to be the Air Capital of the World in the future.”

Work at a dedicated aviation research center will bring in expertise specific to this application, drawing from deep regional roots.

NIAR will now have more opportunity to work closely with America Makes and the previously established Satellite Centers as together these locations draw from resources across this vast nation to further that simple, complex goal of advancing additive manufacturing.

Via America Makes and The Wichita Eagle

Eric Haddad is the founder and Pilot in Command of 3DAeroventures, a Texas-based outfit specializing in 3D printed RC aircraft.