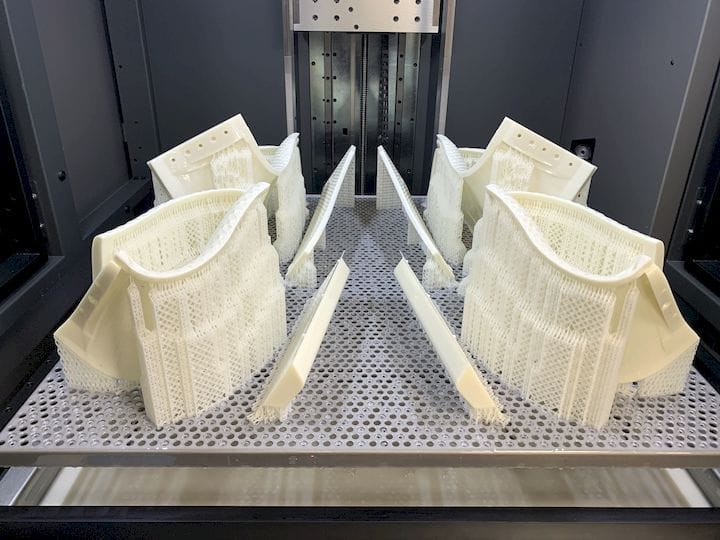

![SLA 3D prints made by the Oxford Brookes Racing team [Source: RPS]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb093c08e0a5.jpg)

Advanced 3D printing is not just the purvey of industry; it can also be done by students.

3D printing is now frequently found in schools across the world to varying degrees. The most frequently seen scenario is a classroom equipped with a basic 3D printer, where students can observe operations and learn about digital manufacturing, albeit starting at a very basic level.

A less common scenario is for students to perform advanced 3D printing with industrial-level equipment and materials. This makes sense, as most students are moving through introductory levels of 3D printing concepts.

Eventually they will graduate and some will work for companies that handle complex engineering and product design projects, increasingly using 3D printing. And that kind of 3D printing typically involves advanced high-temperature materials, unusual fabrication sequences, metals, and highly complex geometries.

That’s not a place for students, or is it?

Industrial 3D Printing For Students?

In some cases, this level of technology is appropriate for students. At senior levels there are student projects that can indeed benefit from the use of 3D printing that’s beyond the basic PLA extrusion systems you often find in classrooms.

One recent example we’ve seen of an education institution using advanced 3D print technology effectively has been Oxford Brookes University in the UK, whose students have entered a team into the Formula Student racing competition.

The Formula Student program is an engineering competition held in the UK and open to universities worldwide, in which students actually build a Formula-level racing vehicle. The competition has been held annually since 1998, and the championship has been won by teams from the US, Canada, Australia, Germany, Sweden, Switzerland, Netherlands, and of course the UK.

The Oxford Brookes Racing team (OBR) team made use of 3D print tech from nearby RPS.

RPS 3D Print Technology

![Some 3D printed parts made by the OBR - RPS collaboration [Source: RPS]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb093c0d1129.jpg)

RPS is a ten-year-old UK-based firm providing a selection of 3D printers, multiple industrial materials and associated services, including 3D printing, engineering, electronics, and computer-aided engineering. They focus primarily on SLA and SLS 3D printing processes, and even manufacture their own NEO800 stereolithography system right in the UK.

RPS explains:

“Students from the aerodynamics team worked with RPS to 3D print moulds using the NEO800 stereolithography system and DSM’s PerFORM resin. As PerFORM can withstand the heat and pressure of an autoclave, the moulds were suitable for carbon fibre layup. The benefits of using the moulds seen by the students were time savings and design freedom, superior sidewall quality and unmatched detail resolution that cannot be achieved using traditional manufacturing methods.”

It seems that the OBR team leveraged multiple capacities from RPS to produce their entry into the Formula Student competition.

Advanced 3D Printing Jobs

If this isn’t advanced use of 3D printing by students, I don’t know what is. Further, this arrangement will surely provide these students with an incredible depth of exposure into the not only the technology, but how it can be practically applied in a real-life industrial scenario.

Building a Formula car is about as advanced as you can get, and these students were able to do so. What better way could there be to prepare students for entry into an industry than this? My suspicion is that these particular students will be quickly scooped up by automotive teams when they graduate.

Via RPS

Healthcare 3D printing attempts to solve two problems that plague providing care: customization and cost.